Content Menu

● What is Tungsten Carbide?

>> Properties of Tungsten Carbide

● Applications of Tungsten Carbide

● Current Market Price of Tungsten Carbide

>> Price Breakdown

● Factors Influencing the Price of Tungsten Carbide

● Historical Price Trends

● Future Outlook

● Conclusion

● FAQ

>> 1. What is the average price of tungsten carbide per gram?

>> 2. Why is tungsten carbide so expensive?

>> 3. Can tungsten carbide be recycled?

>> 4. What industries use tungsten carbide?

>> 5. How does the purity of tungsten carbide affect its price?

● Citations:

Tungsten carbide is a remarkable material known for its exceptional hardness and durability. It is widely used in various industries including manufacturing, construction, and even jewelry. Understanding its value, particularly the price per gram, is essential for businesses and individuals involved in its trade or use. This article explores the worth of tungsten carbide, its applications, market trends, and factors influencing its price.

What is Tungsten Carbide?

Tungsten carbide is a chemical compound consisting of equal parts tungsten and carbon atoms. It is a dense, hard material that is nearly twice as hard as steel. Due to its toughness and resistance to wear, tungsten carbide is used in various applications ranging from industrial tools to jewelry.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide ranks 8.5 to 9 on the Mohs hardness scale, making it one of the hardest materials available.

- Density: It has a density of approximately $$15.6 \, \text{g/cm}^3$$, which contributes to its weight and durability.

- Melting Point: The melting point of tungsten carbide is around $$2,600^\circ C$$ (4,700°F), allowing it to withstand high temperatures without losing structural integrity.

- Corrosion Resistance: It exhibits excellent resistance to corrosion and abrasion, making it suitable for harsh environments.

Applications of Tungsten Carbide

Tungsten carbide's unique properties make it suitable for a wide range of applications:

1. Industrial Tools: Used for cutting, drilling, and grinding tools due to its hardness. Tungsten carbide tools are preferred in machining operations where precision and durability are crucial.

Industrial Tools

2. Jewelry: Popular in wedding bands and fashion jewelry because of its scratch resistance and aesthetic appeal. Tungsten carbide rings are available in various finishes and styles.

3. Aerospace Components: Utilized in parts that require high strength and durability. Components made from tungsten carbide can withstand extreme conditions found in aerospace applications.

4. Mining Equipment: Employed in drill bits and other mining tools to enhance performance. The hardness of tungsten carbide allows it to cut through tough materials effectively.

5. Medical Instruments: Used in surgical tools due to its sharpness and corrosion resistance. Tungsten carbide instruments are known for their longevity and reliability.

Current Market Price of Tungsten Carbide

The price of tungsten carbide can vary significantly based on several factors including purity, form (powder or solid), and market demand. As of early 2025, the price per gram ranges from approximately $0.50 to $55.00 depending on the supplier and specific product type.

Price Breakdown

| Form | Price Range (per gram) |

| Tungsten Carbide Powder | $0.50 - $3.00 |

| Cemented Carbide Rod | $45.00 - $55.00 |

| Jewelry (e.g., rings) | $30 - $100 |

Factors Influencing the Price of Tungsten Carbide

1. Raw Material Costs: The price of tungsten itself fluctuates based on mining output and global demand. Tungsten is primarily mined in countries like China, Russia, and Canada, where geopolitical factors can influence supply.

2. Manufacturing Processes: The complexity of producing tungsten carbide products can affect pricing. Manufacturing techniques such as sintering require advanced technology and skilled labor, contributing to higher costs.

3. Market Demand: Increased demand in industries like construction or aerospace can drive prices up. Economic growth often leads to higher consumption of tungsten carbide products.

4. Geopolitical Factors: Political stability in tungsten-producing countries can impact supply chains. Trade policies, tariffs, and international relations play significant roles in determining availability.

5. Technological Advancements: Innovations in manufacturing processes can lead to more efficient production methods, potentially lowering costs over time.

Historical Price Trends

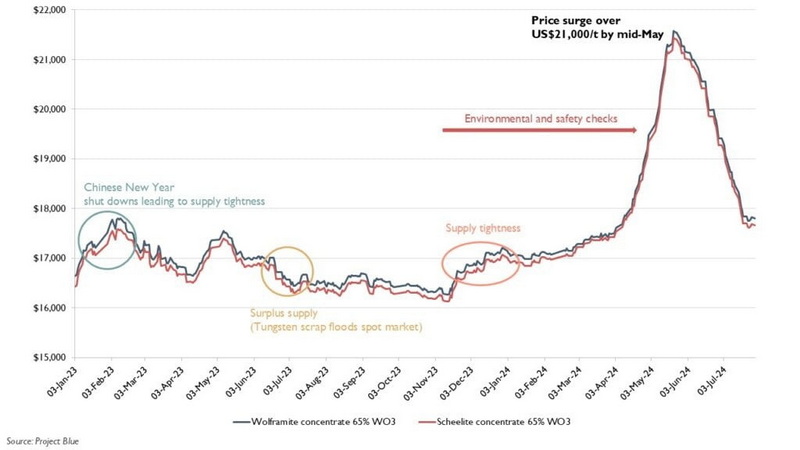

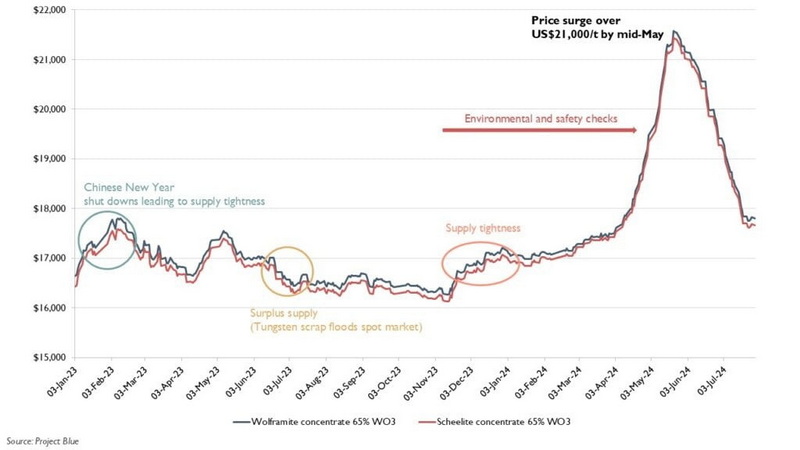

Historically, the price of tungsten carbide has experienced fluctuations due to various economic factors:

- 2000s Boom: The early 2000s saw a surge in demand for tungsten carbide as industries expanded globally.

- 2008 Financial Crisis: Prices dropped significantly during the financial crisis as construction and manufacturing slowed down.

- Recovery Phase (2010s): As economies recovered, demand for tungsten carbide increased again leading to rising prices.

- Recent Trends (2020s): The COVID-19 pandemic caused disruptions in supply chains but also led to increased investment in infrastructure projects post-pandemic.

Future Outlook

The future outlook for tungsten carbide pricing appears optimistic due to several factors:

1. Infrastructure Development: Many governments are investing heavily in infrastructure projects which will increase demand for industrial tools made from tungsten carbide.

2. Technological Innovations: Advances in technology may lead to more efficient production methods that could stabilize or reduce prices.

3. Sustainability Initiatives: As industries move towards sustainable practices, recycled tungsten carbide may become more prevalent, affecting market dynamics.

4. Global Economic Growth: Continued growth in emerging markets may lead to increased consumption across various sectors that utilize tungsten carbide products.

Conclusion

In conclusion, the value of tungsten carbide per gram varies widely based on its form and application. With prices ranging from as low as $0.50 for basic powder to over $55 for specialized industrial components, understanding these dynamics is crucial for anyone involved in purchasing or utilizing this versatile material.

FAQ

1. What is the average price of tungsten carbide per gram?

The average price ranges from $0.50 to $55 depending on the form and application.

2. Why is tungsten carbide so expensive?

Its high cost is attributed to the raw material prices, manufacturing complexities, and market demand.

3. Can tungsten carbide be recycled?

Yes, tungsten carbide can be recycled effectively which helps reduce costs and environmental impact.

4. What industries use tungsten carbide?

Industries such as manufacturing, construction, aerospace, oil & gas, and jewelry utilize tungsten carbide extensively.

5. How does the purity of tungsten carbide affect its price?

Higher purity levels generally lead to increased costs due to better performance characteristics and manufacturing processes.

Citations:

[1] https://www.alibaba.com/showroom/price-for-1-gram-tungsten-carbide.html

[2] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[3] https://almonty.com/tungsten-history/

[4] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[5] https://dir.indiamart.com/impcat/tungsten-powders.html

[6] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[7] https://www.onlinemetals.com/en/buy/tungsten-carbide

[8] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[9] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/