Content Menu

● Key Industrial Applications of Calcium Carbide

● Expanded Industrial Applications of Calcium Carbide

● Innovative Products Containing Calcium Carbide

● Additional Safety Measures

● Safety and Environmental Considerations

● Environmental Impact and Sustainability Efforts

● Future Trends

● Future Research and Development

● Conclusion

● FAQs About Calcium Carbide in Industrial Products

>> 1. What industrial products rely on calcium carbide?

>> 2. How does calcium carbide improve steel quality?

>> 3. Is calcium carbide safe to handle in industrial settings?

>> 4. Can calcium carbide be used in environmentally sensitive industries?

>> 5. What emerging industries use calcium carbide?

Calcium carbide (CaC₂) is a cornerstone of modern industrial chemistry, enabling advancements across sectors from metallurgy to agriculture. As a high-tech enterprise specializing in carbide product development, production, and sales, we recognize its pivotal role in creating durable, efficient solutions for industries like steelmaking, oil drilling, mining, and construction. Below, we explore the diverse applications of calcium carbide in industrial products and its transformative impact on global manufacturing.

Key Industrial Applications of Calcium Carbide

Acetylene Gas Production

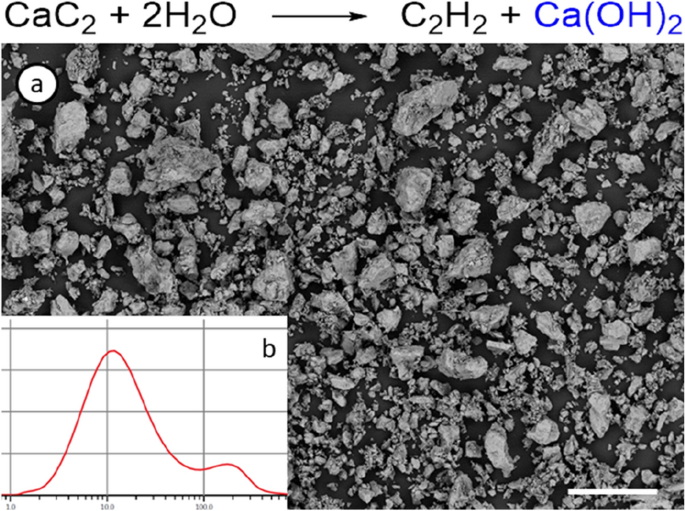

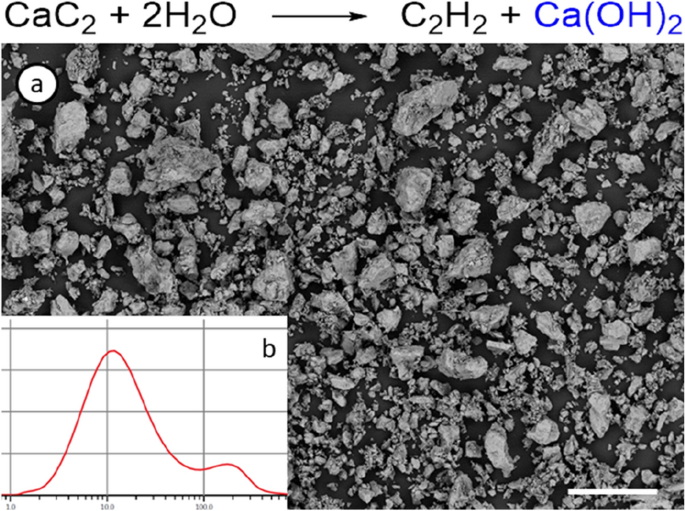

Calcium carbide's most iconic use lies in generating acetylene gas (C₂H₂) through its exothermic reaction with water. Acetylene serves as a critical fuel for:

- Welding and cutting torches in metal fabrication.

- Portable lighting systems for mining and emergency operations.

- Chemical synthesis of plastics, solvents, and synthetic rubber.

Products containing calcium carbide, such as compact acetylene generators, are indispensable in workshops and remote industrial sites where electricity is limited.

Steel and Metallurgy

In steelmaking, calcium carbide acts as a desulfurizing and deoxidizing agent, refining molten iron by removing sulfur and oxygen impurities. This process enhances steel ductility, corrosion resistance, and overall quality. Specific applications include:

- Ladle treatment additives to purify high-grade steel.

- Slag modifiers that recover valuable metals like chromium and manganese.

- Deoxidizers for producing low-oxygen steel alloys.

Industrial products containing calcium carbide, such as powdered desulfurization agents, are vital for manufacturing automotive components, machinery, and construction steel.

Chemical Manufacturing

Calcium carbide is a precursor for numerous chemicals:

- Polyvinyl chloride (PVC): Acetylene derived from CaC₂ is used to produce vinyl chloride monomer, the building block of PVC pipes, cables, and packaging.

- Calcium cyanamide: A nitrogen-rich fertilizer synthesized by reacting calcium carbide with nitrogen.

- Acetic acid and solvents: Key ingredients in pharmaceuticals, textiles, and adhesives.

Mining and Oil Drilling

In mining, calcium carbide-based acetylene lamps provide reliable illumination in underground tunnels. For oil drilling, it aids in well-completion fluids to stabilize boreholes and control pressure.

Construction and Infrastructure

Calcium carbide improves concrete durability by accelerating setting times and reducing water permeability. It also neutralizes acidic soils in land development projects.

Expanded Industrial Applications of Calcium Carbide

Agricultural Uses

Calcium carbide is widely used in agriculture to promote fruit ripening. When calcium carbide reacts with moisture, it releases acetylene gas, which acts as an artificial ripening agent. This application is particularly valuable in regions where natural ripening conditions are not optimal, helping to reduce post-harvest losses and improve marketability of fruits like mangoes, bananas, and tomatoes.

Water Treatment

Calcium carbide derivatives are employed in water treatment processes to remove impurities and neutralize acidic water. Its ability to generate calcium hydroxide upon hydrolysis makes it effective in adjusting pH levels and precipitating heavy metals, thus contributing to safer drinking water and industrial wastewater management.

Electronics and Battery Industry

Emerging uses of calcium carbide include its role in the production of advanced materials for electronics and batteries. Calcium carbide-derived carbon materials are being researched for use in supercapacitors and lithium-ion batteries, offering potential improvements in energy storage capacity and charge-discharge rates.

Innovative Products Containing Calcium Carbide

Modern industries rely on specialized calcium carbide derivatives:

- CaD®: A desulfurization agent for pig iron.

- CalciPro®: Cored wire additives for precise steel treatment.

- Calzot®: Nitrogen-alloying agents for stainless steel.

- Acetylene generators: Portable units for welding and cutting.

- Soil conditioners: Granular products for agricultural use.

Additional Safety Measures

Handling calcium carbide requires strict adherence to safety protocols due to its reactive nature. Industrial facilities implement rigorous training programs for workers, use moisture-proof packaging, and maintain controlled environments to prevent accidental acetylene release. Emergency response plans are also established to address potential fire hazards.

Safety and Environmental Considerations

While calcium carbide is non-toxic, its reaction with water releases flammable acetylene gas. Proper storage in moisture-proof containers and adherence to ventilation protocols are critical. Environmentally, innovations in electric arc furnace technology and closed-loop systems minimize dust and energy waste during production.

Environmental Impact and Sustainability Efforts

The calcium carbide industry is increasingly focused on reducing its environmental footprint. Innovations include the development of cleaner production technologies that minimize greenhouse gas emissions and waste generation. Recycling of calcium hydroxide byproducts into construction materials and soil amendments exemplifies circular economy principles.

Future Trends

The calcium carbide industry is shifting toward sustainable practices, including:

- Recycling byproducts like calcium hydroxide.

- Integrating renewable energy in manufacturing.

- Expanding applications in hydrogen production and battery materials.

Future Research and Development

Research is ongoing to enhance the efficiency of calcium carbide production and expand its applications. Novel catalysts and process optimizations aim to lower energy consumption. Additionally, the exploration of calcium carbide in hydrogen generation aligns with global efforts to transition to clean energy sources.

Conclusion

From refining steel to fueling chemical synthesis, calcium carbide remains a linchpin of industrial innovation. Its versatility in products like desulfurizers, PVC, and construction materials underscores its irreplaceable role in advancing technology and infrastructure. As industries evolve, calcium carbide will continue to drive efficiency, sustainability, and growth.

FAQs About Calcium Carbide in Industrial Products

1. What industrial products rely on calcium carbide?

Products include acetylene generators, steel desulfurizers, PVC plastics, soil conditioners, and mining lamps.

2. How does calcium carbide improve steel quality?

It removes sulfur and oxygen impurities, enhancing strength and corrosion resistance in alloys.

3. Is calcium carbide safe to handle in industrial settings?

Yes, with proper storage and handling to prevent unintended reactions with moisture.

4. Can calcium carbide be used in environmentally sensitive industries?

Advanced production methods and recycling reduce its environmental footprint, making it viable for eco-conscious applications.

5. What emerging industries use calcium carbide?

Hydrogen fuel production and energy storage systems are exploring calcium carbide-derived materials.