Content Menu

● Introduction to Calcium Carbide

>> Calcium Carbide Production Process

● Calcium Carbide Production in China

>> Economic Factors

>> Environmental Challenges

● Applications of Calcium Carbide

● Challenges and Future Developments

>> Modernization Efforts

>> Environmental Initiatives

● Global Market Trends

>> Regional Insights

● Conclusion

● FAQs

>> 1. What is the primary use of calcium carbide in China?

>> 2. How is calcium carbide produced industrially?

>> 3. What are the environmental challenges associated with calcium carbide production?

>> 4. What role does calcium carbide play in steel production?

>> 5. How does China's resource availability influence its calcium carbide production?

● Citations:

Calcium carbide, with the chemical formula CaC₂, is a crucial industrial chemical used in various sectors, including the production of acetylene gas, polyvinyl chloride (PVC), and as a desulfurizing agent in steelmaking. In China, calcium carbide production is a significant industry, driven by the country's vast coal and lime resources. This article will delve into the process of calcium carbide production in China, its applications, and the challenges faced by the industry.

Introduction to Calcium Carbide

Calcium carbide is a greyish-black solid that is insoluble in water. It is produced by reacting calcium oxide (lime) with carbon at high temperatures in an electric arc furnace. The reaction is as follows:

CaO+3C→CaC2+CO

This process requires temperatures around 2,200°C, which cannot be achieved through conventional combustion methods, hence the use of electric arc furnaces.

Calcium Carbide Production Process

The production of calcium carbide involves several key steps:

1. Raw Material Preparation: The primary raw materials are calcium oxide (lime) and carbon, typically in the form of coke. These materials are crushed and mixed in a specific ratio. Lime is usually produced by calcining limestone in a kiln at high temperatures, typically above 900°C, to decompose calcium carbonate into calcium oxide[1][4].

2. Heating in an Electric Arc Furnace: The mixture is then heated in an electric arc furnace at temperatures exceeding 2,000°C. This high temperature is necessary for the reaction between calcium oxide and carbon to occur[1][4].

3. Cooling and Solidification: After the reaction, the molten calcium carbide is cooled and solidified. This process involves tapping the molten carbide into chills where it solidifies[4].

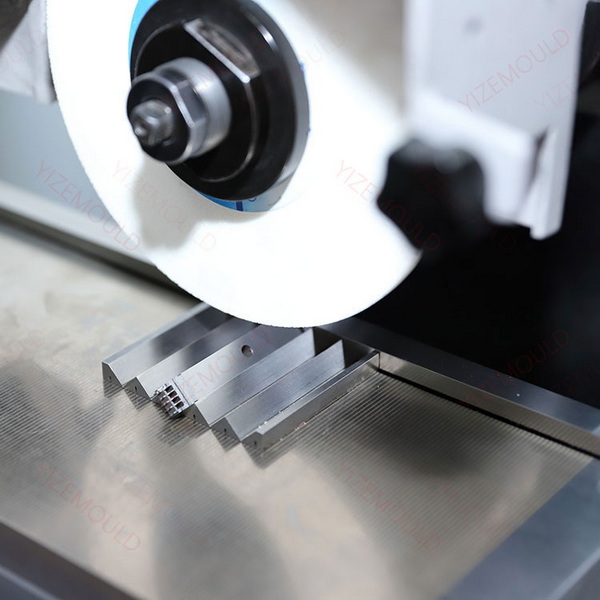

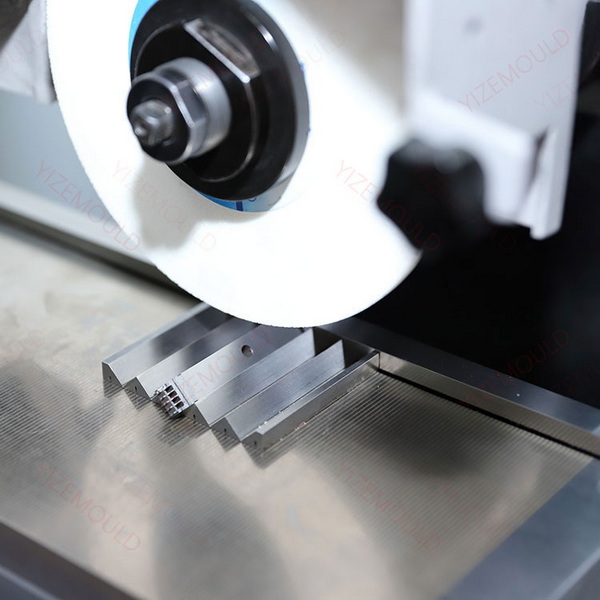

4. Crushing and Grinding: The solidified calcium carbide is then crushed into smaller lumps, typically ranging from a few millimeters to 50 mm in size. This step is crucial for increasing the surface area for subsequent reactions[7].

5. Impurity Removal: The crushed calcium carbide undergoes further processing to remove impurities, enhancing its purity and quality. Impurities such as calcium phosphide can be present and are concentrated in finer fractions[7].

Calcium Carbide Production in China

China is one of the world's largest producers of calcium carbide, leveraging its abundant coal and lime resources. The country's calcium carbide industry has grown rapidly over the past two decades, driven by increasing demand for PVC and other chemicals.

Economic Factors

China's reliance on calcium carbide for PVC production is largely due to economic factors. The country lacks sufficient ethylene resources, which are required for the petrochemical route to PVC. However, it has ample coal and lime, making the calcium carbide route more cost-effective.

Environmental Challenges

Despite its economic advantages, the calcium carbide process poses significant environmental challenges. The production generates large amounts of calcium hydroxide slag, which must be disposed of or reused. Efforts are being made to utilize this slag in cement production, supported by government policies[3].

Applications of Calcium Carbide

Calcium carbide has several key applications:

- Acetylene Production: Calcium carbide reacts with water to produce acetylene gas, which is used in welding and metal cutting. Acetylene is a key component in oxyacetylene welding and cutting processes[2].

- PVC Production: Acetylene derived from calcium carbide is used as a raw material for PVC production in China. PVC is a widely used synthetic plastic in construction and consumer goods[2].

- Steel Making: Calcium carbide is used as a desulfurizing agent in steel production. It helps remove sulfur from iron and steel, improving their quality and strength[2].

- Fertilizers: It is also used to produce calcium cyanamide, a nitrogen fertilizer that helps improve soil quality and promote plant growth[2].

Challenges and Future Developments

The calcium carbide industry in China faces challenges related to energy consumption and environmental impact. However, the sector is expected to continue growing, driven by demand for PVC and other chemicals. Efforts are being made to modernize production processes and improve efficiency.

Modernization Efforts

Chinese firms are investing in larger-scale facilities and more efficient technologies to reduce waste and energy consumption. The proximity of many PVC plants to coal mines allows for cost-effective electricity generation, mitigating some of the energy-related challenges.

Environmental Initiatives

To address environmental concerns, companies like TYWH are implementing advanced dust control systems and moisture prevention measures. These strategies help minimize dust emissions and chemical risks associated with calcium carbide production[3].

Global Market Trends

The global calcium carbide market is experiencing considerable growth, with the Asia-Pacific region dominating due to rapid industrialization and expanding construction activities in countries like China and India[6]. However, the market faces challenges from environmental regulations and the emergence of alternative technologies.

Regional Insights

- Asia-Pacific: This region accounts for over 50% of the global calcium carbide market, driven by industrialization and infrastructure development[6].

- North America: The demand here is driven by the automotive and construction sectors, with moderate growth due to advancements in chemical synthesis technologies[6].

- Europe: Europe faces stringent environmental regulations, impacting calcium carbide production. However, steady demand from steelmaking and chemical sectors continues[6].

Conclusion

Calcium carbide production in China is a significant industry, driven by the country's strategic resource advantages and economic considerations. Despite environmental challenges, the sector continues to grow, with ongoing efforts to modernize and improve efficiency. As demand for PVC and other chemicals increases, calcium carbide will remain a crucial component of China's industrial landscape.

FAQs

1. What is the primary use of calcium carbide in China?

Calcium carbide is primarily used in China for the production of acetylene, which is then used to manufacture polyvinyl chloride (PVC) and other chemicals.

2. How is calcium carbide produced industrially?

Calcium carbide is produced industrially by reacting calcium oxide (lime) with carbon in an electric arc furnace at temperatures around 2,200°C.

3. What are the environmental challenges associated with calcium carbide production?

The production of calcium carbide generates large amounts of calcium hydroxide slag and poses risks from dust emissions and chemical hazards. It also contributes to greenhouse gas emissions due to its energy-intensive nature.

4. What role does calcium carbide play in steel production?

Calcium carbide is used as a desulfurizing agent in steel production, helping to remove sulfur from iron and steel.

5. How does China's resource availability influence its calcium carbide production?

China's abundant coal and lime resources make the calcium carbide route more economical than the petrochemical route, which relies on ethylene. This resource availability is a key factor in China's reliance on calcium carbide for PVC production.

Citations:

[1] https://www.tjtywh.com/a-step-by-step-guide-to-making-calcium-carbide-at-home.html

[2] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-processes-and-applications.html

[3] https://www.tjtywh.com/environmental-challenges-in-calcium-carbide-production-and-tywh-s-solutions.html

[4] https://www3.epa.gov/ttnchie1/ap42/ch11/final/c11s04.pdf

[5] https://www.carbidellc.com/solutions.html

[6] https://www.linkedin.com/pulse/calcium-carbide-market-set-experience-considerable-hyl8c

[7] https://en.wikipedia.org/wiki/Calcium_carbide

[8] https://www.woarjournals.org/admin/vol_issue2/upload%20Image/IJPMR021402.pdf

[9] https://www.transparencymarketresearch.com/calcium-carbide-market.html

[10] https://www.raco.cat/index.php/afinidad/article/download/413451/509559

[11] https://pmc.ncbi.nlm.nih.gov/articles/PMC8911359/

[12] https://www.diva-portal.org/smash/get/diva2:411529/FULLTEXT01.pdf

[13] https://www.eiga.eu/uploads/documents/DOC109.pdf

[14] https://www.mdpi.com/1420-3049/26/9/2568

[15] https://www.ascconline.com/img/services/project_report/Calcium_Carbide_Project_Report_Sample.pdf

[16] https://byjus.com/chemistry/calcium-carbide/

[17] https://www.pyrometallurgy.co.za/InfaconXIV/149-McCaffrey.pdf

[18] https://www.vedantu.com/chemistry/calcium-carbide

[19] https://www.chemanalyst.com/industry-report/calcium-carbide-market-2850

[20] https://www.nature.com/articles/s41598-023-31075-z