Content Menu

● Traditional Production Methods

>> Direct Metal Carbonization

>> Carbothermal Reduction

● Modern Production Techniques

>> Catalyst-Assisted Synthesis

>> Vapor-Phase Halide Method

>> Mechanical Alloying

● Advanced Characterization Techniques

>> Quality Control in Aluminium Carbide Production

● Industrial Applications of Aluminium Carbide

>> Metallurgical Uses

>> Defense Applications

>> Energy Storage Breakthroughs

● Environmental and Safety Considerations

>> Emission Control

>> Waste Management

>> NFPA Hazard Ratings:

● Future Directions in Aluminium Carbide Production

● Conclusion

● FAQ

>> 1. What's the maximum production scale for vapour-phase Al₄C₃?

>> 2. How does particle size affect aluminium carbide reactivity?

>> 3. What PPE is required when handling Al₄C₃?

>> 4. Can aluminium carbide production be automated?

>> 5. What's the typical shelf life of Al₄C₃ powder?

● Citations:

Aluminium carbide (Al₄C₃) is a critical industrial compound with applications spanning metallurgy, military hardware, and advanced ceramics. Its production involves precise chemical reactions and advanced manufacturing techniques to achieve high purity and structural integrity. This article explores traditional and modern methods of aluminium carbide production, their technical nuances, and industrial applications.

Traditional Production Methods

Direct Metal Carbonization

The most straightforward method involves reacting pure aluminium with carbon at extreme temperatures (1,200–1,400°C) in an electric arc furnace:

4Al+3C→Al4C3

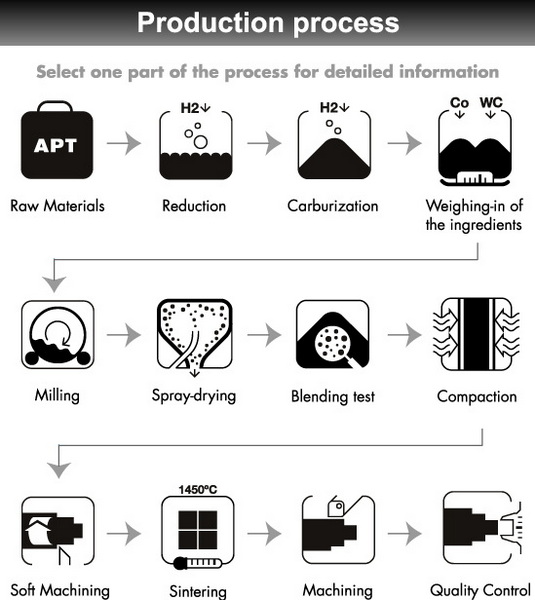

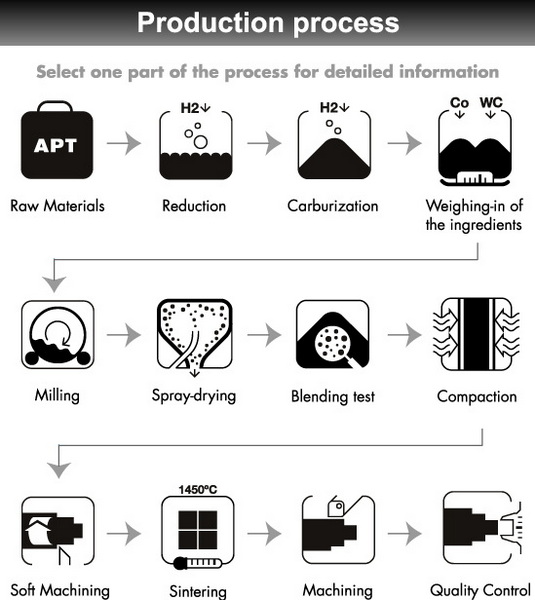

Key stages in aluminium carbide production:

1. Material Preparation

- Aluminium powder (99.9% purity, 50-100 μm particle size)

- Carbon sources: Graphite flakes (preferred) or carbon black

- Mixing ratio: 3:1 molar (Al:C) homogenized via ball milling

2. Reactor Configuration

- Graphite-lined crucibles with water-cooled copper electrodes

- Inert gas purge (Argon flow rate: 5-10 L/min)

3. Thermal Profile

- Ramp-up: 10°C/min to 1,200°C

- Hold time: 24-48 hours

- Cooling: Controlled at 5°C/min to prevent crack formation

Quality Indicators:

- X-ray diffraction (XRD) purity: ≥95%

- Bulk density: 2.36 g/cm3

- Grain size: 10-50 μm

Carbothermal Reduction

This cost-effective method uses aluminium oxide (Al₂O₃) instead of metallic Al:

2Al2O3+9C→Al4C3+6CO

Process Innovations:

Feedstock Optimization:

Alumina/carbon blend with 10% excess carbon compensates for CO loss

Vacuum Furnace Design:

- Operating pressure: 102 Torr

- Zirconia-based insulation withstands 1,800°C

Byproduct Management:

- CO gas scrubbed through NaOH solution (pH 12.5)

- Carbon recovery rate: 88-92%

Industrial Data:

| Parameter | Value |

| Production Rate | 50 kg/batch |

| Energy Consumption | 8.2 kWh/kg |

| Typical Impurities | Si (0.3%), Fe (0.1%) |

Modern Production Techniques

Catalyst-Assisted Synthesis

Process Flow:

- Catalyst loading: 5-8 wt%

- Self-propagating reaction ignition at 700°C

- Reaction completion in 3.5 hours

Vapor-Phase Halide Method

High-Purity Aluminium Carbide Production Flow:

1. AlCl₃ Generation:

2Al+3Cl2→2AlCl3

- Chlorination at 500°C

2. AlCl Formation:

Al+AlCl3→2AlCl

- Vapor transport at 1,100°C

3. Carburization:

4AlCl+3C→Al4C3+3Cl2

- Fluidized bed reactor with 0.5-1 mm carbon granules

Key Advantages:

- Purity: 99.97% (SEM-EDS verified)

- Crystal structure: Hexagonal platelets (10-20 μm)

Mechanical Alloying

Nanostructured Aluminium Carbide Production:

Ball Milling Parameters:

| Variable | Specification |

| Milling Media | WC-Co balls (10 mm) |

| Speed | 300 RPM |

| Atmosphere | Argon (O₂ < 5 ppm) |

| Duration | 18-24 hours |

Phase Evolution:

- 0-6h: Al/C mechanical mixing

- 6-12h: Amorphous phase formation

- 12-18h: Crystalline Al₄C₃ nucleation

Structural Properties:

- Grain size: 35-80 nm (TEM confirmed)

- Microhardness: 1,850 HV

Advanced Characterization Techniques

Quality Control in Aluminium Carbide Production

1. Chemical Analysis:

- LECO combustion for carbon content

- ICP-OMS for metallic impurities

2. Morphological Study:

- SEM imaging of fracture surfaces

- BET surface area analysis

3. Thermal Stability:

- TGA up to 1,500°C in N₂ atmosphere

Industrial Applications of Aluminium Carbide

Metallurgical Uses

Case Study: Titanium Sponge Production

Reaction:

3TiO2+4Al4C3→3Ti+8Al2O3+12C

Benefits:

- 98.5% Ti purity vs 94% with conventional Mg reduction

- 22% lower energy consumption

Defense Applications

Armor Composite Formula:

- 60% Al₄C₃

- 30% SiC

- 10% epoxy resin

- Ballistic limit: 1,850 m/s against 7.62mm AP

Energy Storage Breakthroughs

Methane Generation Efficiency:

| Parameter | Batch Reactor | Flow System |

| CH₄ Yield | 72% | 89% |

| Reaction Time | 6 hours | 1.5 hours |

| Water Consumption | 12 L/kg | 8 L/kg |

Environmental and Safety Considerations

Emission Control

CO/Cl₂ scrubbing systems:

- Packed bed towers with 15% NaOH solution

- 99.8% gas neutralization efficiency

Waste Management

Spent crucibles processed via:

- Acid leaching (HCl 6M, 80°C)

- Al recovery rate: 97.3%

NFPA Hazard Ratings:

- Health: 3 (Severe)

- Flammability: 1 (Mild)

- Reactivity: 2 (Moderate)

Future Directions in Aluminium Carbide Production

1. Plasma-Assisted Synthesis

- Microwave plasma (2.45 GHz) reduces reaction time to <30 minutes

2. Additive Manufacturing

- Binder jet 3D printing of Al₄C₃-SiC composites

3. Green Chemistry Approaches

- Biomass-derived carbon sources (e.g., coconut shell char)

Conclusion

Modern aluminium carbide production combines precision thermodynamics with advanced material engineering, yielding tailored products for extreme environments. While traditional carbothermal methods remain industry staples, emerging techniques like catalyst-assisted synthesis and mechanical alloying open new frontiers in nano-structured materials. Ongoing R&D focuses on energy efficiency gains and circular economy integration through improved recycling protocols.

FAQ

1. What's the maximum production scale for vapour-phase Al₄C₃?

Current systems achieve 200 kg/day using multi-zone fluidized bed reactors.

2. How does particle size affect aluminium carbide reactivity?

Sub-50 μm powders increase hydrolysis rates by 3x compared to 100-200 μm grades.

3. What PPE is required when handling Al₄C₃?

Essential gear includes:

- N95 respirators (for dust)

- Acid-resistant gloves

- Face shields during high-temperature processing

4. Can aluminium carbide production be automated?

Yes – modern plants use AI-controlled furnaces with ±2°C temperature accuracy.

5. What's the typical shelf life of Al₄C₃ powder?

12 months in argon-filled sealed containers, with <0.1% moisture ingress.

Citations:

[1] https://patents.google.com/patent/US2640760A/en

[2] https://www.nanotrun.com/article/preparation-methods-and-application-of-aluminum-carbide-i00101i1.html

[3] https://en.wikipedia.org/wiki/Aluminium_carbide

[4] https://www.youtube.com/watch?v=95yS7W66-BI

[5] https://patents.google.com/patent/US2942951A/en

[6] https://testbook.com/question-answer/aluminium-carbide-on-hydrolysis-gives-a-compound--60ae0a9776162bb0ee6bd90e

[7] https://www.vedantu.com/question-answer/aluminium-carbide-reacts-with-water-to-form-a-class-11-chemistry-cbse-5f1a1e7114b5e05976ab1490

[8] https://www.americanelements.com/aluminum-carbide-1299-86-1

[9] https://jmmab.com/wp-content/uploads/2020/12/1450-53392000023W-cc1.pdf

[10] https://www.nanorh.com/product/aluminium-carbide-powder/

[11] https://www.practicalmachinist.com/forum/threads/steel-grade-carbide-on-aluminum.85961/

[12] https://www.albmaterials.com/high-purity-materials/1227-high-purity-aluminum-carbide-al4c3.html

[13] https://www.goodfellow.com/global/aluminium-carbide-powder-group

[14] https://www.istockphoto.com/photos/aluminum-machining

[15] https://www.sigmaaldrich.com/US/en/search/aluminium-carbide?focus=products&page=1&perpage=30&sort=relevance&term=aluminium+carbide&type=product_name

[16] https://www.shutterstock.com/search/alumina-production

[17] https://www.britannica.com/science/aluminum-carbide

[18] https://pubchem.ncbi.nlm.nih.gov/compound/16685054

[19] https://www.t3db.ca/toxins/T3D1492

[20] https://www.linkedin.com/pulse/understanding-aluminium-carbide-production-costs-enhanced-gautam-cgiuc

[21] https://melscience.com/US-en/articles/hydrolysis-aluminum-carbide-equation-and-nature-re/

[22] https://www.istockphoto.com/photos/carbide

[23] https://www.linkedin.com/pulse/answering-25-most-asked-questions-aluminum-casting-iaj6c