Content Menu

● Introduction to Calcium Carbide

>> Production Process of Calcium Carbide

● Role of Calcium Carbide in Acetylene Production

>> Advantages of Calcium Carbide in Acetylene Production

● Applications of Acetylene Gas

● Challenges and Considerations

● Environmental Solutions

>> Advanced Dust Control Systems

>> Moisture Prevention Measures

● Innovative Production Techniques

● Applications Beyond Acetylene Production

● Impact of Environmental Regulations

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary use of calcium carbide?

>> 2. How is calcium carbide produced?

>> 3. What are the advantages of using high-quality calcium carbide in acetylene production?

>> 4. What are some common applications of acetylene gas?

>> 5. What safety precautions should be taken when handling calcium carbide?

● Citations:

Calcium carbide (CaC₂) is a crucial compound in the industrial production of acetylene gas (C₂H₂), which is widely used in various sectors such as welding, chemical synthesis, and manufacturing. The reaction between calcium carbide and water is the foundation of acetylene production, making calcium carbide an indispensable raw material in this process. In this article, we will delve into the core role of calcium carbide in acetylene production, its advantages, and its applications across different industries.

Introduction to Calcium Carbide

Calcium carbide is a greyish-black solid compound produced through the reaction of quicklime (calcium oxide) and carbon in an electric arc furnace. The chemical equation for this process is:

CaO+3C→CaC2+CO

This reaction requires high temperatures, typically around 2,200 °C, and is an endothermic process, meaning it absorbs energy to proceed.

Production Process of Calcium Carbide

The production of calcium carbide involves several steps:

1. Extraction of Calcium Carbonate: Calcium carbonate is extracted from limestone.

2. Formation of Quicklime: Calcium carbonate is heated to form quicklime (calcium oxide).

3. Reaction in Electric Arc Furnace: Quicklime is combined with carbon in an electric arc furnace to produce calcium carbide.

Role of Calcium Carbide in Acetylene Production

Calcium carbide plays a pivotal role in the production of acetylene gas through its reaction with water. The chemical reaction is as follows:

CaC2+2H2O→C2H2+Ca(OH)2

This reaction is highly exothermic, releasing a significant amount of heat, and is the basis for industrial acetylene production.

Advantages of Calcium Carbide in Acetylene Production

1. Efficient Gas Yield: High-quality calcium carbide ensures a higher yield of acetylene gas, reducing raw material costs and improving production efficiency. The purity and reactivity of calcium carbide directly influence the volume and quality of acetylene produced.

2. Gas Purity: The purity of calcium carbide is crucial for maintaining the purity of acetylene gas. Impurities in calcium carbide, such as sulfur, phosphorus, and iron, can contaminate the acetylene, affecting its performance in downstream applications.

Applications of Acetylene Gas

Acetylene gas produced from calcium carbide is used in various industrial applications:

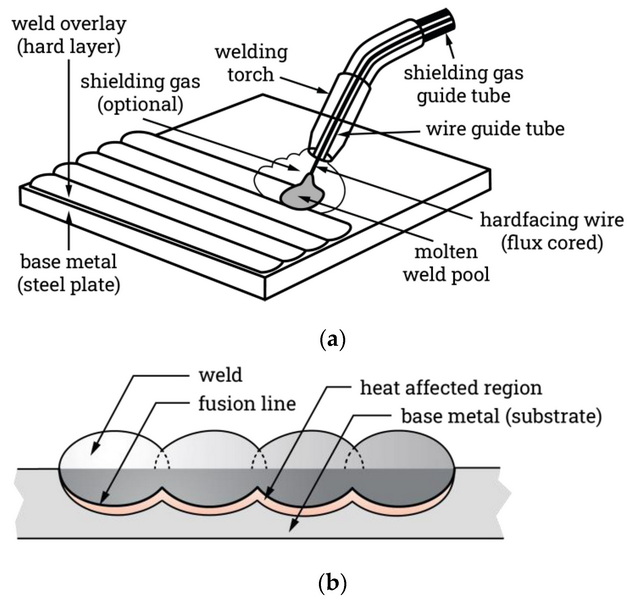

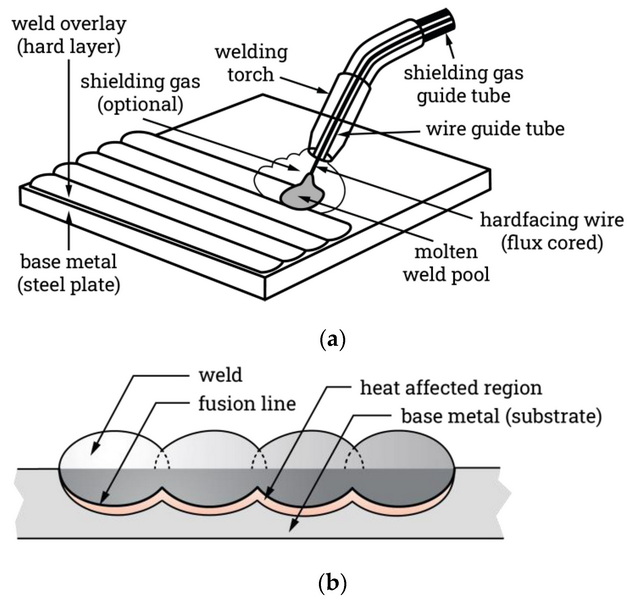

1. Welding and Metal Cutting: Acetylene is used in oxy-acetylene torches for welding and cutting metals due to its high flame temperature. This process is widely used in metal fabrication and construction industries.

2. Chemical Synthesis: Acetylene serves as a precursor in the synthesis of vinyl chloride, used in PVC production, and other organic compounds. It is also used in the production of solvents, plastics, and synthetic rubber.

3. Steel Manufacturing: Acetylene is used in the desulfurization of steel, improving its quality and strength.

4. Lighting: Historically, acetylene was used in lighting devices such as carbide lamps, providing a portable light source before electric lighting became prevalent.

5. Oil and Gas Industry: Acetylene is utilized for detecting and testing gas leaks.

Challenges and Considerations

While calcium carbide is essential for acetylene production, there are challenges and considerations:

1. Safety: The reaction between calcium carbide and water is highly exothermic and can be dangerous if not handled properly. It requires strict temperature control and safety measures to prevent accidents.

2. Environmental Impact: The production process requires significant energy and can have environmental implications if not managed sustainably. Dust emissions and chemical risks associated with calcium carbide handling need to be addressed.

3. Storage and Transportation: Calcium carbide must be stored in dry, well-ventilated areas away from water sources to prevent unwanted reactions. Proper labeling and emergency preparedness are crucial.

Environmental Solutions

To mitigate environmental challenges, manufacturers like TYWH have implemented advanced dust control systems and moisture prevention measures. These include sealed production equipment and efficient dust collection systems to ensure air quality meets international standards.

Advanced Dust Control Systems

TYWH employs state-of-the-art dust collection systems in crushing, screening, and packaging facilities:

- High Efficiency: Captures over 95% of dust particles, ensuring air quality meets international environmental standards.

- Safe Processing: Collected dust is safely processed and neutralized to protect workers and the environment.

Moisture Prevention Measures

TYWH prioritizes moisture control during calcium carbide production to mitigate chemical risks:

- Sealed Production Equipment: Effectively isolates calcium carbide from contact with ambient moisture, reducing material degradation and acetylene gas risks.

- Efficient Handling: Ensures that calcium carbide is handled in a manner that minimizes exposure to moisture.

Innovative Production Techniques

Recent innovations in acetylene production aim to enhance safety and efficiency. For instance, the use of nitrogen to replace air in production units helps reduce oxygen levels, ensuring a safer operating environment[1]. Additionally, advanced gas purification systems are employed to remove impurities from acetylene gas, improving its quality for downstream applications[1].

Applications Beyond Acetylene Production

Calcium carbide has applications beyond acetylene production:

1. Steel Hardening and Desulfurization: Calcium carbide is used to remove sulfur impurities from steel, enhancing its quality and strength[2][7].

2. Production of Calcium Cyanamide: Calcium carbide is used to produce calcium cyanamide, a nitrogen fertilizer that improves soil quality[2][7].

3. Synthetic Rubber and Plastics: Calcium carbide is involved in the synthesis of organic compounds used in the production of synthetic rubber and plastics[2].

Impact of Environmental Regulations

Environmental regulations have a significant impact on calcium carbide production and supply chains. Stricter controls on emissions and energy efficiency push manufacturers to adopt cleaner technologies, which can increase production costs but ensure compliance with international standards[8].

Conclusion

Calcium carbide is a vital component in the production of acetylene gas, offering efficient gas yield and purity. Its applications span across welding, chemical synthesis, and steel manufacturing. As demand for high-quality acetylene continues to grow, the importance of calcium carbide in these processes will remain significant. Moreover, addressing environmental challenges through innovative solutions is crucial for sustainable production.

Frequently Asked Questions

1. What is the primary use of calcium carbide?

Calcium carbide is primarily used in the production of acetylene gas through its reaction with water. This acetylene gas is then used in various industrial applications such as welding, metal cutting, and chemical synthesis.

2. How is calcium carbide produced?

Calcium carbide is produced by reacting quicklime (calcium oxide) with carbon in an electric arc furnace at high temperatures.

3. What are the advantages of using high-quality calcium carbide in acetylene production?

High-quality calcium carbide ensures a higher gas yield and purity of acetylene, reducing raw material costs and improving production efficiency.

4. What are some common applications of acetylene gas?

Acetylene gas is commonly used in welding and metal cutting due to its high flame temperature, and in chemical synthesis for producing vinyl chloride and other organic compounds.

5. What safety precautions should be taken when handling calcium carbide?

Handling calcium carbide requires strict safety measures due to its highly reactive nature. It should be stored in a dry environment and handled with caution to avoid accidental reactions with water.

Citations:

[1] https://patents.google.com/patent/CN105085148A/en

[2] https://www.ascconline.com/img/services/project_report/Calcium_Carbide_Project_Report_Sample.pdf

[3] https://www.tjtywh.com/environmental-challenges-in-calcium-carbide-production-and-tywh-s-solutions.html

[4] https://www.carbidellc.com/Info/SafetyDoc/CIGenerating%20Booklet.pdf

[5] https://www.aist.org/new-partnership-to-introduce-calcium-carbide-based-eaf-slag-technology

[6] https://www3.epa.gov/ttnchie1/ap42/ch11/final/c11s04.pdf

[7] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-processes-and-applications.html

[8] https://www.tjtywh.com/how-environmental-regulations-impact-global-calcium-carbide-production-and-supply-chains.html

[9] https://uploads-ssl.webflow.com/5e64c5ff68556aceba38e5ef/5ea2c3814ee5d3f198ef995f_TD_32_19_E.pdf

[10] https://www.tjtywh.com/technological-innovations-in-calcium-carbide-clean-production-and-automated-production-lines.html

[11] https://www.alzchem.com/en/company/news/calcium-carbide-for-acetylene-production/

[12] https://www.taiwannews.com.tw/news/5880375

[13] https://www.diva-portal.org/smash/get/diva2:411529/FULLTEXT01.pdf

[14] https://nj.gov/health/eoh/rtkweb/documents/fs/0312.pdf

[15] https://www.pyrometallurgy.co.za/InfaconXIV/149-McCaffrey.pdf

[16] https://www.eiga.eu/uploads/documents/DOC226.pdf

[17] https://www.tjtywh.com/a-exploring-the-practical-applications-of-calcium-carbide.html

[18] https://www.raco.cat/index.php/afinidad/article/download/413451/509559

[19] https://law.resource.org/pub/in/bis/S02/is.6819.1973.pdf

[20] http://jbb.xml-journal.net/article/doi/10.1016/j.jobab.2020.04.002