Content Menu

● Understanding Sanding Tools

● Advantages of Carbide Sanding Plates

>> 1. Durability

>> 2. Efficiency

>> 3. Versatility

>> 4. Reduced Dust

>> 5. Cost-Effectiveness

● Disadvantages of Carbide Sanding Plates

>> 1. Initial Cost

>> 2. Learning Curve

>> 3. Limited Grit Options

● Applications of Carbide Sanding Plates

>> 1. Woodworking

>> 2. Automotive Refinishing

>> 3. Home Renovation

>> 4. Crafting

>> 5. Restoration Projects

● How to Use Carbide Sanding Plates

● Conclusion

● Frequently Asked Questions

>> 1. What is a carbide sanding plate?

>> 2. Can carbide sanding plates be used on all surfaces?

>> 3. How do I maintain a carbide sanding plate?

>> 4. Are carbide sanding plates worth the investment?

>> 5. What are the best applications for carbide sanding plates?

When it comes to woodworking and various DIY projects, the tools you choose can significantly impact the quality of your work. Among these tools, sanding is a crucial step that can determine the smoothness and finish of your project. In recent years, carbide sanding plates have gained popularity, but how do they stack up against traditional sanding tools? This article will explore the differences, advantages, and applications of carbide sanding plates compared to traditional sanding tools.

Understanding Sanding Tools

Before diving into the comparison, it's essential to understand what sanding tools are available and their purposes. Traditional sanding tools include:

- Sandpaper: Available in various grits, sandpaper is the most common sanding tool. It can be used manually or attached to power sanders.

- Sanding Blocks: These are handheld tools that hold sandpaper, providing a flat surface for sanding.

- Orbital Sanders: These power tools use circular sanding pads and are ideal for smoothing surfaces quickly.

- Belt Sanders: These are powerful tools that use a continuous loop of sandpaper to remove material quickly.

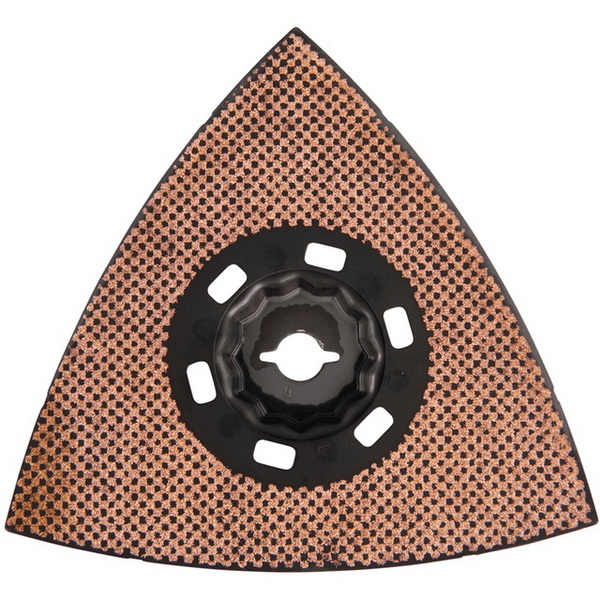

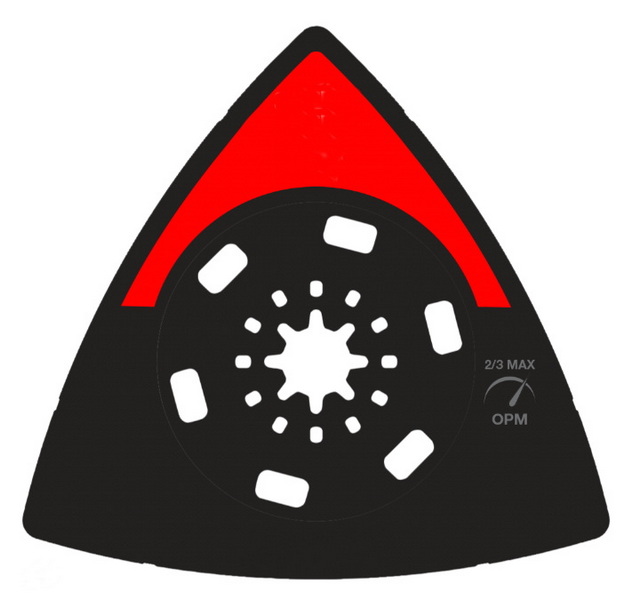

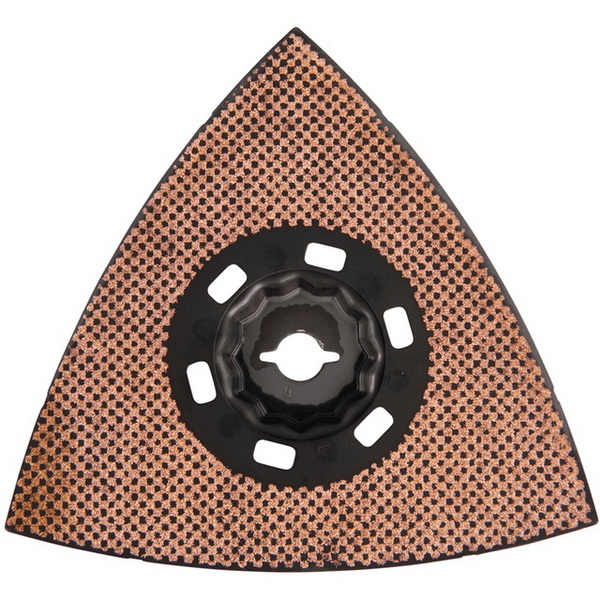

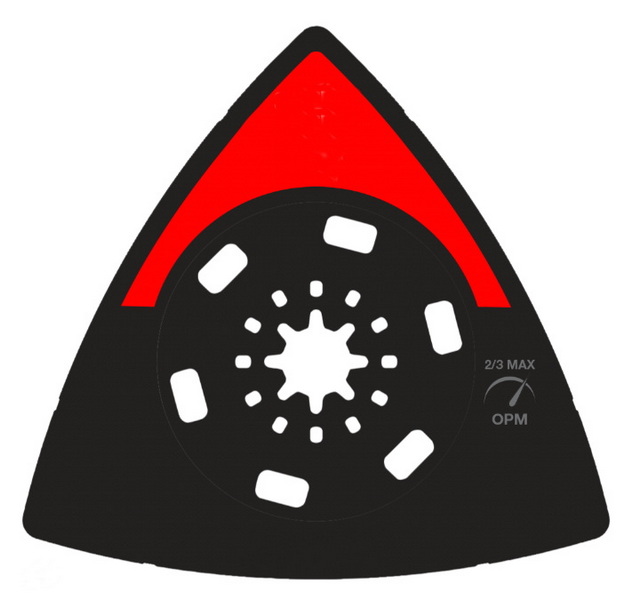

On the other hand, carbide sanding plates are relatively new entrants in the sanding world. They are typically made from tungsten carbide, a material known for its durability and hardness. These plates can be attached to various power tools, such as oscillating multi-tools and sanders, making them versatile for different applications.

Advantages of Carbide Sanding Plates

1. Durability

One of the most significant advantages of carbide sanding plates is their durability. Tungsten carbide is one of the hardest materials available, making these plates resistant to wear and tear. Unlike traditional sandpaper, which can quickly become dull and ineffective, carbide sanding plates maintain their cutting ability for a much longer time. This durability translates to less frequent replacements, saving both time and money in the long run.

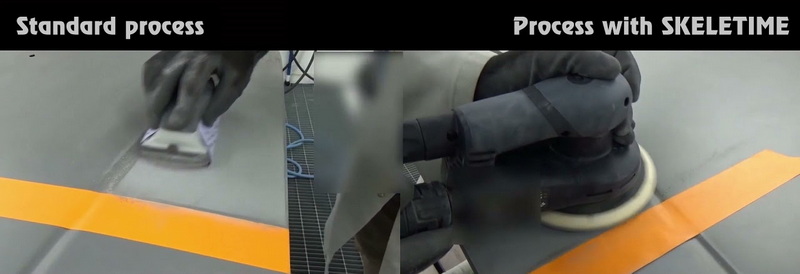

2. Efficiency

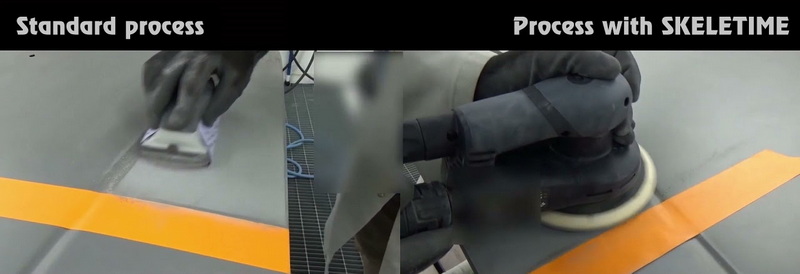

Carbide sanding plates are designed to remove material quickly and efficiently. Their sharp edges can cut through wood, paint, and other materials with ease. This efficiency is particularly beneficial for larger projects or when working with tough materials. Users often find that they can complete tasks faster with carbide sanding plates compared to traditional sanding methods.

3. Versatility

Carbide sanding plates can be used on various surfaces, including wood, metal, and plastic. This versatility makes them an excellent choice for different projects, from woodworking to automotive refinishing. Additionally, they can be used in tight spaces and on intricate designs, thanks to their compatibility with oscillating tools.

4. Reduced Dust

Another advantage of carbide sanding plates is their ability to produce less dust compared to traditional sanders. This is particularly important for those who are sensitive to dust or working in enclosed spaces. The design of carbide plates allows for more efficient material removal, which means less dust is generated during the sanding process.

5. Cost-Effectiveness

While carbide sanding plates may have a higher upfront cost compared to traditional sandpaper, their longevity and efficiency can make them more cost-effective over time. Users often find that they need to purchase fewer replacement plates, which can offset the initial investment.

Disadvantages of Carbide Sanding Plates

Despite their many advantages, carbide sanding plates are not without drawbacks. Here are a few considerations:

1. Initial Cost

As mentioned, carbide sanding plates can be more expensive than traditional sandpaper. For hobbyists or those on a tight budget, this initial cost may be a barrier to entry.

2. Learning Curve

Using carbide sanding plates may require a slight learning curve, especially for those accustomed to traditional sanding methods. Users may need to adjust their techniques to maximize the benefits of carbide plates.

3. Limited Grit Options

While traditional sandpaper is available in a wide range of grits, carbide sanding plates may have fewer options. This limitation can affect the finish quality for specific applications, particularly when fine sanding is required.

Applications of Carbide Sanding Plates

Carbide sanding plates are suitable for various applications, including:

1. Woodworking

In woodworking, carbide sanding plates excel at removing material quickly and efficiently. They are ideal for shaping wood, smoothing surfaces, and preparing pieces for finishing. Whether you are working on furniture, cabinetry, or decorative items, carbide sanding plates can help achieve a professional finish.

2. Automotive Refinishing

Carbide sanding plates are also popular in automotive refinishing. They can effectively remove paint, rust, and other materials from metal surfaces, making them a valuable tool for auto body shops. The ability to quickly strip old paint and prepare surfaces for new finishes is crucial in the automotive industry.

3. Home Renovation

For home renovation projects, carbide sanding plates can be used to prepare surfaces for painting or staining. Their ability to remove old finishes and smooth surfaces makes them a go-to choice for many DIY enthusiasts. Whether you are refinishing cabinets or prepping walls for paint, carbide sanding plates can save time and effort.

4. Crafting

Crafters can benefit from carbide sanding plates when working with various materials. Their versatility allows for intricate designs and detailed work, making them suitable for a wide range of crafting projects. From model building to jewelry making, carbide sanding plates can enhance the quality of your finished products.

5. Restoration Projects

Carbide sanding plates are also ideal for restoration projects, such as refinishing antique furniture or restoring vintage items. Their ability to remove layers of old paint or varnish without damaging the underlying material makes them a valuable tool for restorers. This precision is essential when working with delicate or valuable pieces.

How to Use Carbide Sanding Plates

Using carbide sanding plates is relatively straightforward, but here are some tips to ensure optimal results:

1. Choose the Right Tool: Ensure that your power tool is compatible with carbide sanding plates. Most oscillating multi-tools and sanders will work well.

2. Select the Appropriate Grit: While carbide sanding plates may have limited grit options, choose the one that best suits your project. For rough material removal, opt for a coarser grit, while finer grits are better for finishing.

3. Maintain a Steady Hand: When sanding, maintain a steady hand and apply even pressure. This technique will help achieve a smooth finish and prevent uneven surfaces.

4. Keep the Tool Moving: Avoid staying in one spot for too long, as this can create gouges or uneven surfaces. Keep the tool moving to ensure an even finish.

5. Wear Protective Gear: Always wear appropriate protective gear, such as goggles and a dust mask, to protect yourself from dust and debris.

6. Clean the Surface Regularly: Periodically stop to clean the surface you are sanding. This will help you see your progress and prevent dust buildup, which can affect the sanding efficiency.

7. Experiment with Angles: Depending on the project, you may find that sanding at different angles can yield better results. Experiment with the angle of the sanding plate to see what works best for your specific application.

Conclusion

In conclusion, carbide sanding plates offer several advantages over traditional sanding tools, including durability, efficiency, and versatility. While they may come with a higher initial cost and a slight learning curve, their long-term benefits make them a worthwhile investment for many woodworkers, DIY enthusiasts, and professionals alike. Understanding the differences between carbide sanding plates and traditional sanding tools can help you make informed decisions for your projects, ultimately leading to better results and a more enjoyable sanding experience.

Frequently Asked Questions

1. What is a carbide sanding plate?

A carbide sanding plate is a sanding tool made from tungsten carbide, known for its durability and efficiency in material removal.

2. Can carbide sanding plates be used on all surfaces?

Yes, carbide sanding plates can be used on various surfaces, including wood, metal, and plastic.

3. How do I maintain a carbide sanding plate?

To maintain a carbide sanding plate, keep it clean and free from debris. Avoid excessive pressure during use to prolong its lifespan.

4. Are carbide sanding plates worth the investment?

Yes, while they may have a higher upfront cost, their durability and efficiency can make them more cost-effective over time.

5. What are the best applications for carbide sanding plates?

Carbide sanding plates are ideal for woodworking, automotive refinishing, home renovation, crafting, and restoration projects.