Content Menu

● Introduction

● Understanding Chromium Carbide Overlay Plates

● Key Benefits of Chromium Carbide Overlay Plates

>> A. Wear Resistance

>> B. Impact Resistance

>> C. Temperature Tolerance

● Applications of Chromium Carbide Overlay Plates

>> A. Mining and Quarrying

>> B. Construction

>> C. Manufacturing

● Installation and Maintenance

>> Best Practices for Installing Carbide Overlay Plates

>> Maintenance Tips to Extend the Lifespan of the Plates

● Conclusion

● Frequently Asked Questions

>> Q1. What is the primary advantage of using chromium carbide overlay plates?

>> Q2. In which industries are chromium carbide overlay plates commonly used?

>> Q3. How do I maintain chromium carbide overlay plates?

>> Q4. Can chromium carbide overlay plates withstand high temperatures?

>> Q5. What is the installation process for carbide overlay plates?

Introduction

In the realm of industrial applications, the choice of materials can significantly impact the efficiency and longevity of equipment. One such material that has gained prominence is the carbide steel plate, particularly the chromium carbide overlay plate. These plates are engineered to withstand extreme conditions, making them ideal for various industries, including mining, construction, and manufacturing. This article delves into the benefits of using chromium carbide overlay plates, exploring their unique properties, applications, and maintenance practices.

Understanding Chromium Carbide Overlay Plates

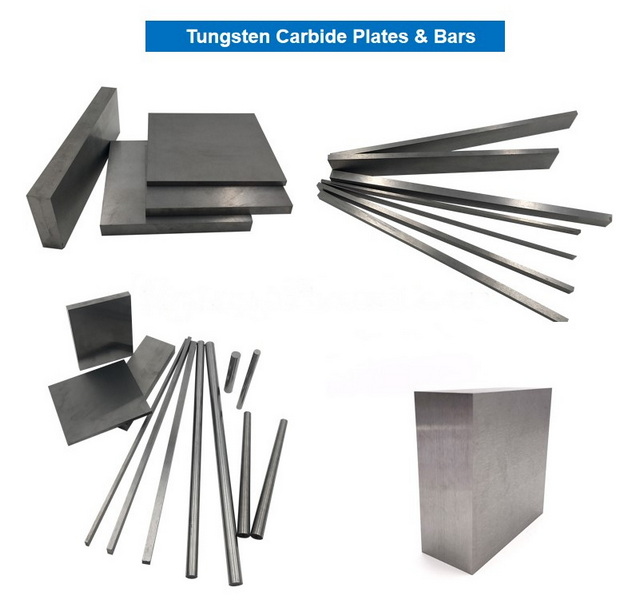

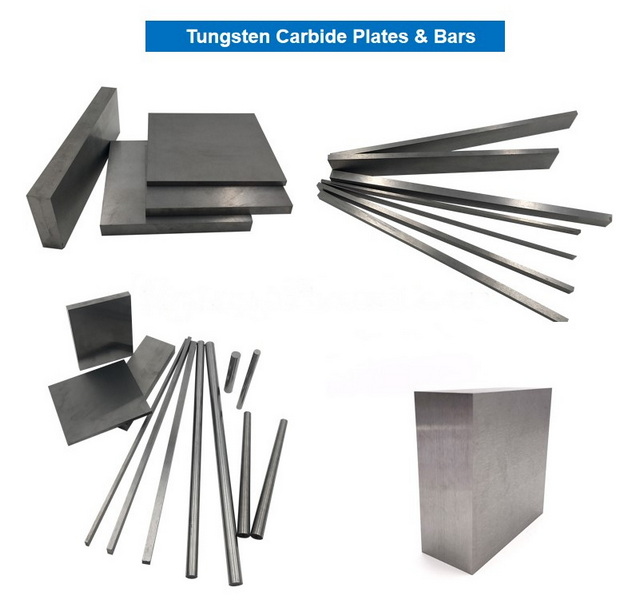

Chromium carbide overlay plates are composite materials that consist of a mild steel base with a layer of chromium carbide. This combination results in a product that offers superior hardness and wear resistance compared to traditional steel plates. The chromium carbide layer is typically applied through a welding process, creating a robust bond that enhances the plate's durability.

The primary advantage of chromium carbide overlay plates lies in their ability to resist wear and tear. In environments where equipment is subjected to high abrasion, these plates can significantly extend the lifespan of machinery. Unlike standard steel plates, which may wear down quickly under harsh conditions, carbide steel plates maintain their integrity, reducing the need for frequent replacements.

Key Benefits of Chromium Carbide Overlay Plates

A. Wear Resistance

One of the standout features of chromium carbide overlay plates is their exceptional wear resistance. In industries such as mining and quarrying, equipment is often exposed to abrasive materials that can cause significant damage. The hardness of chromium carbide, which can reach up to 60 HRC (Rockwell Hardness), allows these plates to withstand the rigors of such environments.

For instance, in a mining operation, the use of chromium carbide overlay plates on conveyor belts and chutes can prevent premature wear, ensuring that these components function efficiently for longer periods. This not only saves costs associated with replacements but also minimizes downtime, allowing operations to run smoothly.

B. Impact Resistance

In addition to wear resistance, chromium carbide overlay plates exhibit excellent impact resistance. This property is crucial in applications where equipment faces heavy loads and sudden impacts. The toughness of the carbide layer helps absorb shocks, preventing cracks and fractures that could lead to equipment failure.

For example, in construction sites where heavy machinery is used, the risk of impact damage is high. By incorporating chromium carbide overlay plates into the design of buckets and blades, operators can enhance the durability of their equipment, ensuring it can handle the demands of the job without compromising performance.

C. Temperature Tolerance

Another significant advantage of chromium carbide overlay plates is their ability to withstand high temperatures. In many industrial applications, equipment is exposed to extreme heat, which can weaken traditional materials. However, the thermal stability of chromium carbide allows these plates to maintain their properties even in elevated temperatures.

This characteristic is particularly beneficial in industries such as steel manufacturing, where equipment is often subjected to intense heat. By using carbide steel plates, manufacturers can ensure that their machinery remains operational, reducing the risk of thermal fatigue and extending the lifespan of critical components.

Applications of Chromium Carbide Overlay Plates

A. Mining and Quarrying

In the mining and quarrying sectors, chromium carbide overlay plates are invaluable. They are commonly used in equipment such as excavators, loaders, and conveyor systems. The harsh conditions of these environments necessitate materials that can withstand abrasive wear, and carbide overlay plates fit the bill perfectly.

For instance, the use of these plates in bucket liners can significantly enhance the performance of excavators, allowing them to dig through tough materials without suffering from rapid wear. Similarly, conveyor systems equipped with carbide overlay plates can transport materials more efficiently, reducing the risk of breakdowns.

B. Construction

The construction industry also benefits from the use of chromium carbide overlay plates. Heavy machinery, such as bulldozers and graders, often encounters abrasive surfaces that can lead to wear and tear. By integrating carbide steel plates into these machines, operators can enhance their durability and performance.

For example, the blades of bulldozers can be fitted with chromium carbide overlay plates to improve their cutting efficiency and resistance to wear. This not only extends the life of the equipment but also ensures that construction projects can be completed on time and within budget.

C. Manufacturing

In manufacturing processes, the need for durable materials is paramount. Chromium carbide overlay plates are used in various applications, including wear plates for machinery and components that experience high levels of friction. Their ability to resist wear makes them ideal for use in manufacturing environments where precision and reliability are essential.

For instance, in the production of cement, equipment such as mixers and hoppers can benefit from the use of carbide overlay plates. These plates can withstand the abrasive nature of cement, ensuring that the machinery operates efficiently without frequent maintenance.

Installation and Maintenance

Best Practices for Installing Carbide Overlay Plates

Proper installation of chromium carbide overlay plates is crucial to maximizing their benefits. It is essential to ensure that the plates are welded correctly to the base material to create a strong bond. This process typically involves preheating the base material and using appropriate welding techniques to avoid defects.

Additionally, it is important to select the right thickness of the overlay plate based on the specific application. Thicker plates may offer more wear resistance but can also add weight to the equipment, potentially affecting performance. Therefore, a careful assessment of the operational conditions is necessary to determine the optimal thickness.

Maintenance Tips to Extend the Lifespan of the Plates

To ensure the longevity of chromium carbide overlay plates, regular maintenance is essential. Here are some tips to help extend their lifespan:

1. Regular Inspections: Conduct routine inspections to identify any signs of wear or damage. Early detection can prevent further deterioration and costly repairs.

2. Cleaning: Keep the plates clean from debris and abrasive materials that can cause unnecessary wear. Regular cleaning can help maintain their performance.

3. Lubrication: In applications where friction is a concern, proper lubrication can reduce wear on the plates and enhance their performance.

4. Monitoring Operating Conditions: Be aware of the operating conditions and adjust processes as needed to minimize excessive wear. For example, reducing the speed of conveyor belts can help extend the life of the overlay plates.

5. Professional Maintenance: Engage professionals for maintenance and repairs to ensure that the plates are handled correctly and any issues are addressed promptly.

Conclusion

Chromium carbide overlay plates offer a multitude of benefits for industrial applications, including exceptional wear and impact resistance, temperature tolerance, and versatility across various sectors. Their ability to withstand harsh conditions makes them an invaluable asset in industries such as mining, construction, and manufacturing. By understanding the advantages and proper maintenance of these plates, businesses can enhance their operational efficiency and reduce costs associated with equipment failure.

As industries continue to evolve, the demand for durable materials like chromium carbide overlay plates will only increase. Investing in these advanced materials is not just a choice; it is a strategic decision that can lead to significant long-term benefits.

Frequently Asked Questions

Q1. What is the primary advantage of using chromium carbide overlay plates?

The primary advantage of chromium carbide overlay plates is their exceptional wear resistance, which allows them to withstand harsh conditions and extend the lifespan of equipment.

Q2. In which industries are chromium carbide overlay plates commonly used?

Chromium carbide overlay plates are commonly used in industries such as mining, construction, and manufacturing, where equipment is exposed to abrasive materials and high wear conditions.

Q3. How do I maintain chromium carbide overlay plates?

To maintain chromium carbide overlay plates, conduct regular inspections, keep them clean, lubricate as needed, monitor operating conditions, and engage professionals for maintenance.

Q4. Can chromium carbide overlay plates withstand high temperatures?

Yes, chromium carbide overlay plates exhibit excellent temperature tolerance, making them suitable for applications where equipment is exposed to extreme heat.

Q5. What is the installation process for carbide overlay plates?

The installation process involves welding the plates to the base material, ensuring a strong bond. Proper techniques and preheating are essential to avoid defects during installation.