Content Menu

● Introduction

● The Role of Biomass Carbide Hammers in Mining Operations

● Advantages of Biomass Carbide Hammer Products

>> Enhanced Durability and Longevity

>> Improved Cost Efficiency

>> Consistent Particle Size Distribution

>> Versatility Across Materials

● Applications in Mining Workflows

>> 1. Primary and Secondary Crushing

>> 2. Mineral Processing Plants

>> 3. Underground Mining

>> 4. Specialty Operations

● Technological Innovations in Biomass Carbide Hammers

>> Precision Manufacturing Techniques

>> Customizable Configurations

>> Smart Monitoring Systems

● Environmental and Safety Benefits

>> Reduced Waste Generation

>> Energy Efficiency

>> Worker Safety

● Case Study: Australian Iron Ore Operation

● Conclusion

● FAQs

>> 1. How does tungsten carbide improve mining hammer lifespan?

>> 2. Are biomass carbide hammers customizable for different ores?

>> 3. What maintenance practices maximize carbide hammer efficiency?

>> 4. Can these hammers reduce energy consumption in mills?

>> 5. Do biomass carbide hammers suit high-moisture environments?

● Citations:

Introduction

Biomass carbide hammer products represent a technological leap in mining tool engineering, combining tungsten carbide's robustness with advanced manufacturing techniques. These hammers are integral to crushing, milling, and material reduction processes, where their superior wear resistance and longevity directly translate to enhanced operational efficiency. In mining, where equipment faces extreme abrasion and impact stresses, biomass carbide hammers reduce downtime, lower maintenance costs, and optimize resource extraction. This article explores their role, benefits, applications, and innovations in modern mining operations.

The Role of Biomass Carbide Hammers in Mining Operations

Mining operations rely heavily on crushing and grinding machinery to process extracted minerals. Biomass carbide hammers, installed in crushers and hammer mills, are critical for:

1. Material Size Reduction

- Breaking down ore, coal, and hard rock into manageable particles (e.g., reducing 500 mm boulders to 25 mm fragments).

- Ensuring uniform particle size for downstream processing (e.g., smelting, leaching).

- Biomass carbide hammer products maintain consistent output even in high-throughput environments (up to 2,000 tons/hour).

2. Wear Resistance in Harsh Environments

- Tungsten carbide overlays (1–3 mm thick) on hammer blades withstand abrasive materials like quartz (7 Mohs) and granite (6–7 Mohs).

- Field tests show biomass carbide hammers last 7–8 times longer** than traditional 65Mn steel hammers, reducing replacement frequency from weekly to bi-annually.

3. High-Impact Performance

- Withstand repetitive strikes at rotational speeds up to 3,000 RPM without deformation.

- Energy transfer efficiency improves by 22% compared to manganese steel due to reduced elastic deformation.

Mining crusher with carbide hammers Caption: Crushers equipped with carbide hammers process hard rock efficiently.

Advantages of Biomass Carbide Hammer Products

Enhanced Durability and Longevity

- Tungsten carbide's hardness (9.5 Mohs) outperforms tool steel (6.5–7.5 Mohs), reducing wear rates by 80% in silica-rich ores.

- Reduced downtime: Continuous operation periods extend from 200 hours (steel hammers) to 1,500 hours (carbide hammers).

- Case study: At a Chilean copper mine, switching to biomass carbide hammer products reduced crusher maintenance stops from 12 to 2 per year.

Improved Cost Efficiency

- Lower lifecycle costs: Initial costs of $8,000–$12,000 per hammer are offset by a 3–5 year lifespan versus 6–8 months for steel.

- Energy savings: Precision grinding reduces power consumption by 15–20%, saving $45,000 annually per 500 kW crusher.

Consistent Particle Size Distribution

- Adjustable screen sizes (3–50 mm) and hammer tip speeds (35–55 m/s) ensure uniform output (±2% size variance).

- Optimizes downstream processes like flotation (recovery rates improve by 5–7%).

Versatility Across Materials

- Effective on coal (soft), iron ore (medium), quartzite (hard), and recycled mining waste.

- Specialized designs for sticky materials: Anti-clogging grooves reduce material adhesion by 40%.

Applications in Mining Workflows

1. Primary and Secondary Crushing

- Jaw crushers: Carbide hammers process 1,200–1,500 MPa compressive strength ores.

- Gyratory crushers: Handle 5,000 tph throughput with 200–300 mm feed sizes.

- Impact crushers: Achieve 20:1 reduction ratios in limestone quarries.

2. Mineral Processing Plants

- Ball mills: Grind ores to 75 μm for efficient metal liberation.

- SAG mills: Biomass carbide hammer liners reduce media consumption by 30%.

3. Underground Mining

- Continuous miners: Carbide picks cut coal seams at 15–25 m/minute.

- Roadheaders: Tunnel 5–8 meters daily with 50% fewer tool replacements.

4. Specialty Operations

- Oil sands processing: Carbide scrapers handle viscous bitumen with 90% less wear than steel.

- Precious metal recovery: Minimal iron contamination from hammer wear improves gold purity by 0.3–0.5%.

Technological Innovations in Biomass Carbide Hammers

Precision Manufacturing Techniques

- Laser cladding: Deposits 0.8–1.2 mm carbide layers with 99.9% density for optimal wear resistance.

- Isostatic pressing: Creates uniform carbide structures with <0.5% porosity.

- Balanced rotors: Maintain vibration levels below 6.3 mm/s RMS for bearing longevity.

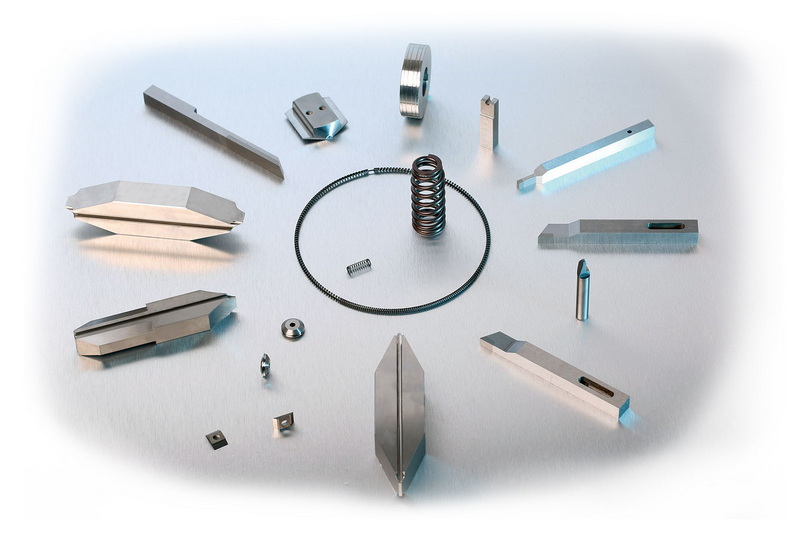

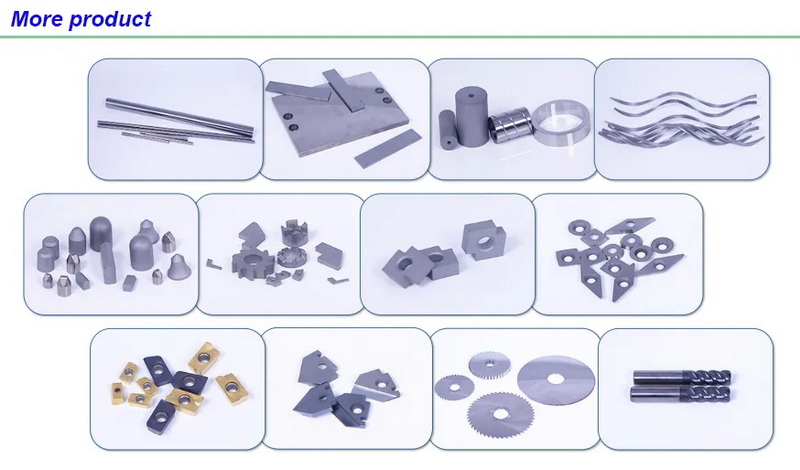

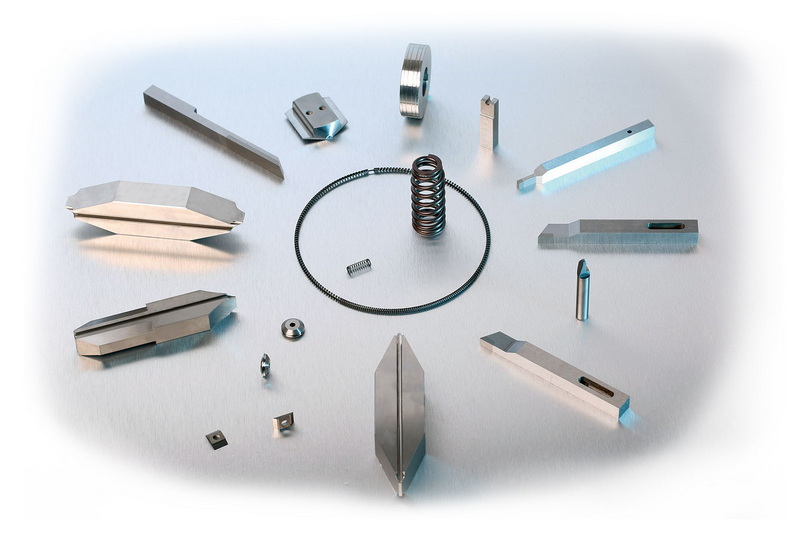

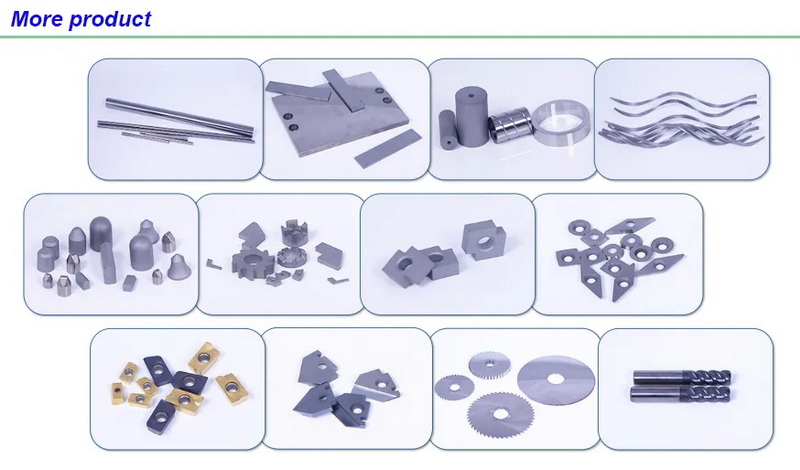

Customizable Configurations

- Weight options: 15–120 kg hammers for crushers ranging from 500 HP to 2,500 HP.

- Tip geometries: Chisel, block, or hybrid designs for specific ore fragmentation needs.

Smart Monitoring Systems

IoT sensors: Track real-time parameters:

- Wear depth (accuracy: ±0.1 mm)

- Temperature (range: -40°C to 300°C)

- Impact forces (up to 50 kN measurement)

- Predictive algorithms forecast replacements with 95% accuracy, reducing unplanned downtime by 70%.

Smart monitoring of carbide hammers Caption: Real-time wear analytics optimize maintenance schedules.

Environmental and Safety Benefits

Reduced Waste Generation

- Longer service life decreases spent hammer disposal by 85% (from 12 tons/year to 1.8 tons for mid-sized mines).

- Tungsten carbide is 98% recyclable through hydrometallurgical processes.

Energy Efficiency

- Lower power consumption per ton processed:

| Material | Steel Hammers (kWh/t) | Carbide Hammers (kWh/t) |

| Iron Ore | 2.8 | 2.3 |

| Copper | 3.5 | 2.9 |

| Gold Quartz | 4.2 | 3.4 |

Worker Safety

Fewer hammer replacements reduce exposure to:

- High-noise environments (saves 120 man-hours/year in maintenance)

- Confined crusher chamber entries

Case Study: Australian Iron Ore Operation

A Pilbara-region mine achieved these results after adopting biomass carbide hammer products:

| Metric | Before | After | Improvement |

| Crusher Availability | 82% | 94% | +12% |

| Maintenance Cost | $1.2M/year | $340k/year | -72% |

| Throughput | 4,800 tpd | 5,400 tpd | +12.5% |

| Energy Use | 28 kWh/t | 23 kWh/t | -18% |

Conclusion

Biomass carbide hammer products revolutionize mining efficiency through material science excellence and smart engineering. Their 7–8x lifespan extension over conventional tools, combined with 15–20% energy savings and IoT-enabled predictive maintenance, make them indispensable in modern mineral processing. As the industry moves toward net-zero operations, these hammers' recyclability and efficiency gains position them as critical components in sustainable mining strategies. Future advancements in nano-structured carbides and AI-driven wear prediction will further solidify their dominance in extractive technologies.

FAQs

1. How does tungsten carbide improve mining hammer lifespan?

Tungsten carbide's hardness (9.5 Mohs) and fracture toughness (12–16 MPa√m) resist abrasive wear and micro-chipping, extending service life to 18–24 months versus 2–3 months for steel.

2. Are biomass carbide hammers customizable for different ores?

Yes. Parameters like carbide grade (YG8/YG11), tip angle (90°–120°), and weight distribution can be optimized for specific ore hardness (Bond Work Index 5–25 kWh/t).

3. What maintenance practices maximize carbide hammer efficiency?

- Rotate hammers every 400 operating hours to equalize wear

- Use laser profilometry to measure wear depth monthly

- Maintain crusher alignment within 0.2 mm/m to prevent uneven loading

4. Can these hammers reduce energy consumption in mills?

Yes. Their efficient kinetic energy transfer lowers specific grinding energy by 0.5–1.2 kWh/t, saving $50k–$120k annually per mill.

5. Do biomass carbide hammers suit high-moisture environments?

Absolutely. The cobalt binder in WC-Co carbides provides corrosion resistance up to pH 3–11, ideal for wet processing and seawater operations.

Citations:

[1] https://www.justmensrings.com/blogs/justmensrings/choosing-between-tungsten-and-titanium-rings-for-sensitive-skin

[2] https://unitedsealing.com/tungsten-carbide-nickel-bonded/

[3] https://www.thorstenrings.com/products/shipton-tungsten-carbide-ring-with-brushed-center-and-beveled-edges-10mm

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://www.jewelryinnovations.com/product-category/mens-rings/rugged-tungsten-bands/

[6] https://metalmastersco.com/collections/tungsten

[7] http://www.titaniumkay.com/tungsten-carbide-facts.aspx

[8] https://www.happylaulea.com/collections/tungsten-carbide

[9] https://ridge.com/collections/tungsten-rings

[10] https://newmanbands.com/are-tungsten-carbide-rings-hypoallergenic/

[11] https://tn-uk.com/tungsten-carbide-balls-nickel-binder/

[12] https://www.larsonjewelers.com/pages/about-tungsten

[13] https://www.elmajewelry.com/nickel-free-tungsten-c-247_428_427.html

[14] https://www.larsonjewelers.com/collections/hypoallergenic-wedding-rings-and-bands

[15] https://stock.adobe.com/search?k=tungsten+carbide

[16] https://www.istockphoto.com/photos/tungsten-carbide

[17] https://www.elmajewelry.com/5mm-nickel-free-tungsten-wedding-ring-band-p-1195.html

[18] https://tritonjewelry.com/collections/tungsten-carbide

[19] https://periodictable.com/Elements/074/pictures.html