Content Menu

● Introduction to RCBS Carbide Pistol Dies

● Understanding the RCBS 3-Die Carbide Set

>> Carbide Sizing Die: The Foundation of Precision

>> Expander Die: Preparing for the Perfect Bullet Fit

>> Bullet Seating Die: The Final Touch of Precision

● The Advantages of RCBS Carbide Pistol Dies

>> 1. Superior Durability

>> 2. Consistent Performance

>> 3. Time and Cost Savings

>> 4. Versatility

● Setting Up Your RCBS Carbide Pistol Dies

>> 1. Press Installation

>> 2. Adjusting the Sizing Die

>> 3. Setting the Expander Die

>> 4. Fine-Tuning the Seating Die

>> 5. Test and Refine

● Maintenance and Care of Your RCBS Carbide Pistol Dies

● Advanced Techniques with RCBS Carbide Pistol Dies

>> 1. Bullet Seating Depth Experimentation

>> 2. Custom Crimp Profiles

>> 3. Case Trimming Integration

● Conclusion: Elevating Your Handgun Ammunition with RCBS Carbide Pistol Dies

● Frequently Asked Questions

>> 1. What is the advantage of carbide dies over standard steel dies?

>> 2. Can RCBS carbide pistol dies be used for both straight-walled and bottleneck pistol cartridges?

>> 3. How often should I replace my RCBS carbide pistol dies?

>> 4. Can I use RCBS carbide pistol dies with progressive reloading presses?

>> 5. Is it necessary to adjust RCBS carbide pistol dies for different bullet weights or styles?

Introduction to RCBS Carbide Pistol Dies

For handgun enthusiasts and avid shooters, the world of ammunition reloading opens up a realm of possibilities. At the heart of this precision craft lies an essential tool: the RCBS carbide pistol die set. These high-quality reloading dies have revolutionized the way handgun owners approach their ammunition needs, offering unparalleled accuracy, consistency, and cost-effectiveness.

RCBS, a name synonymous with quality in the reloading community, has been at the forefront of innovation in reloading equipment for decades. Their carbide pistol dies represent the pinnacle of reloading technology, designed to meet the exacting standards of both novice reloaders and seasoned professionals alike.

Understanding the RCBS 3-Die Carbide Set

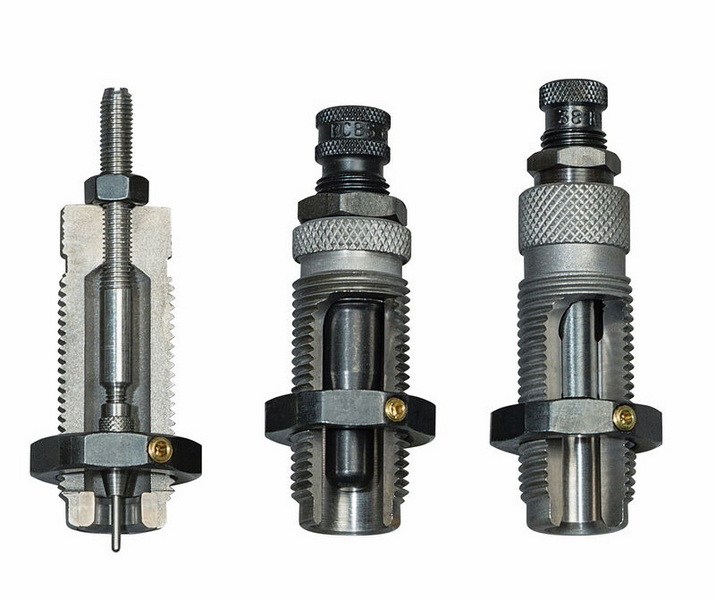

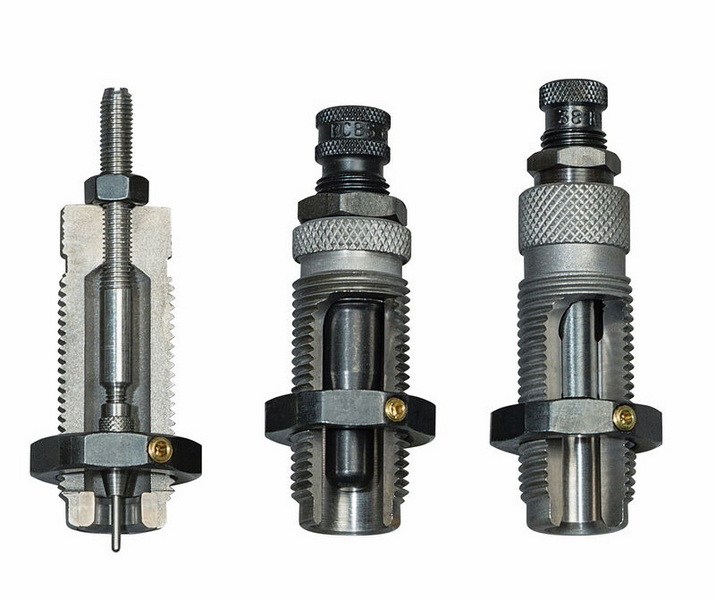

The RCBS 3-die carbide set is the cornerstone of pistol reloading. This comprehensive set typically includes three essential dies:

1. Carbide Sizing Die

2. Expander Die

3. Bullet Seating Die

Each of these dies plays a crucial role in the reloading process, ensuring that your handcrafted ammunition meets or exceeds factory specifications.

Carbide Sizing Die: The Foundation of Precision

The carbide sizing die is the first step in the reloading process. Its primary function is to resize the fired brass case to its original dimensions, ensuring proper fit in your firearm's chamber. The use of tungsten carbide in the construction of this die offers several advantages:

- Eliminates the need for case lubrication

- Extends the life of the die

- Reduces wear on brass cases

- Ensures consistent sizing across thousands of rounds

The carbide sizing die also incorporates a decapping pin, which removes the spent primer from the case during the sizing operation, streamlining the reloading process.

Expander Die: Preparing for the Perfect Bullet Fit

Following the sizing operation, the expander die takes center stage. This die serves two critical functions:

1. It slightly expands the case mouth to the proper diameter for accepting a new bullet.

2. It creates a slight bell or flare at the case mouth, facilitating easier bullet seating.

The precision-engineered expander die ensures that your cases are perfectly prepared for the next stage of the reloading process, contributing to overall accuracy and consistency in your finished ammunition.

Bullet Seating Die: The Final Touch of Precision

The bullet seating die is where the magic happens. This die performs two crucial operations:

1. Seating the bullet to the correct depth in the case

2. Applying a taper crimp to secure the bullet in place

RCBS bullet seating dies are renowned for their adjustability and precision. They allow reloaders to fine-tune the seating depth to match their firearm's specific requirements, optimizing accuracy and performance.

The Advantages of RCBS Carbide Pistol Dies

Investing in RCBS carbide pistol dies offers numerous benefits for the discerning handgun enthusiast:

1. Superior Durability

The use of tungsten carbide in the construction of RCBS dies ensures exceptional longevity. These dies can process tens of thousands of rounds without showing signs of wear, making them a wise long-term investment for serious reloaders.

2. Consistent Performance

RCBS carbide pistol dies are precision-machined to exacting tolerances. This attention to detail translates into consistent performance round after round, ensuring that your handloaded ammunition meets the highest standards of accuracy and reliability.

3. Time and Cost Savings

The elimination of case lubrication with carbide sizing dies not only saves time but also reduces the mess associated with traditional steel dies. This efficiency allows reloaders to produce more ammunition in less time, maximizing their reloading sessions.

4. Versatility

RCBS offers carbide die sets for a wide range of popular pistol calibers, including:

- 9mm Luger

- .40 S&W

- .45 ACP

- .38 Special/.357 Magnum

- 10mm Auto

This versatility ensures that regardless of your preferred handgun caliber, there's an RCBS carbide die set to meet your reloading needs.

Setting Up Your RCBS Carbide Pistol Dies

Proper setup of your RCBS carbide pistol dies is crucial for achieving optimal results. Here's a step-by-step guide to getting started:

1. Press Installation

Begin by installing the dies in your reloading press according to the manufacturer's instructions. RCBS dies are compatible with most standard reloading presses, ensuring a seamless integration into your existing setup.

2. Adjusting the Sizing Die

Start with the sizing die. Lower the ram to its lowest position and screw the die into the press until it contacts the shell holder. Give it an additional 1/4 to 1/2 turn to ensure proper sizing. Lock the die in place using the lock ring.

3. Setting the Expander Die

Install the expander die, adjusting it so that it expands the case mouth just enough to allow for easy bullet seating. The goal is to create a slight bell without overworking the brass.

4. Fine-Tuning the Seating Die

The seating die requires the most precise adjustment. Start by setting it to seat the bullet to the desired overall length (OAL) for your specific load. Then, adjust the crimp to secure the bullet without deforming it.

5. Test and Refine

Always start with a few test rounds, measuring each one for consistency in OAL and checking for proper crimp. Make small adjustments as needed until you achieve the desired results.

Maintenance and Care of Your RCBS Carbide Pistol Dies

To ensure the longevity and continued performance of your RCBS carbide pistol dies, proper maintenance is essential:

1. Clean the dies regularly with a solvent to remove any buildup of carbon or debris.

2. Inspect the decapping pin in the sizing die for signs of wear or damage, replacing it if necessary.

3. Apply a light coat of gun oil to the exterior of the dies to prevent rust.

4. Store your dies in a cool, dry place when not in use, preferably in their original packaging or a dedicated die box.

Advanced Techniques with RCBS Carbide Pistol Dies

As you become more proficient with your RCBS carbide pistol dies, you may want to explore advanced reloading techniques:

1. Bullet Seating Depth Experimentation

Fine-tuning bullet seating depth can have a significant impact on accuracy. Use the adjustable seating stem to experiment with different depths, always staying within safe pressure limits.

2. Custom Crimp Profiles

The taper crimp die can be adjusted to create custom crimp profiles for different bullet types or shooting applications. This level of customization allows you to optimize your loads for specific firearms or competitive shooting disciplines.

3. Case Trimming Integration

For even greater precision, consider incorporating a case trimming step into your reloading process. RCBS offers case trimmers that work seamlessly with their die sets, ensuring consistent case lengths for improved accuracy and reliability.

Conclusion: Elevating Your Handgun Ammunition with RCBS Carbide Pistol Dies

RCBS carbide pistol dies represent the gold standard in handgun ammunition reloading. Their precision engineering, durability, and user-friendly design make them an invaluable tool for anyone serious about crafting custom pistol ammunition. Whether you're a competitive shooter seeking the ultimate in accuracy or a recreational enthusiast looking to save money on range time, RCBS carbide pistol dies offer the performance and reliability you need to take your handloading to the next level.

By investing in a quality set of RCBS carbide pistol dies and taking the time to master their use, you'll open up a world of possibilities in terms of ammunition customization and performance. The satisfaction of creating your own precisely tailored handgun loads, coupled with the cost savings and increased understanding of your firearm's capabilities, makes reloading with RCBS carbide pistol dies a rewarding pursuit for any dedicated handgun enthusiast.

Frequently Asked Questions

1. What is the advantage of carbide dies over standard steel dies?

Answer: Carbide dies offer several advantages over standard steel dies. The primary benefit is that they eliminate the need for case lubrication during the sizing process, which saves time and reduces mess. Carbide dies are also more durable, lasting longer than steel dies and maintaining their precision over a greater number of reloads. Additionally, carbide dies are gentler on brass cases, potentially extending the life of your reloading components.

2. Can RCBS carbide pistol dies be used for both straight-walled and bottleneck pistol cartridges?

Answer: RCBS carbide pistol dies are primarily designed for straight-walled pistol cartridges such as 9mm Luger, .45 ACP, and .40 S&W. For bottleneck pistol cartridges like .357 SIG or 10mm Auto, RCBS offers specific die sets that may include both carbide and steel components to address the unique requirements of these cartridge designs. Always check the specifications of the die set to ensure it's appropriate for your specific cartridge.

3. How often should I replace my RCBS carbide pistol dies?

Answer: RCBS carbide pistol dies are built to last and can process tens of thousands of rounds before showing signs of wear. With proper care and maintenance, many reloaders report using their carbide dies for decades without needing replacement. However, it's important to regularly inspect your dies for any signs of damage or wear, particularly the decapping pin and expander ball. If you notice any issues affecting the quality of your reloads, it may be time to replace individual components or the entire die set.

4. Can I use RCBS carbide pistol dies with progressive reloading presses?

Answer: Yes, RCBS carbide pistol dies are compatible with most progressive reloading presses, as well as single-stage and turret presses. The standard 7/8"-14 thread used on RCBS dies ensures broad compatibility across various press designs. When using carbide dies in a progressive press, be sure to follow the press manufacturer's recommendations for die setup and adjustment to achieve optimal performance and consistency.

5. Is it necessary to adjust RCBS carbide pistol dies for different bullet weights or styles?

Answer: While RCBS carbide pistol dies are designed to accommodate a range of bullet weights and styles within a given caliber, some adjustments may be necessary when switching between significantly different bullet types. The seating die, in particular, may require adjustment to achieve the correct overall length (OAL) and crimp for different bullet profiles. It's always recommended to start with a few test rounds and measure the results carefully when changing bullet types, making small adjustments to the dies as needed to ensure proper fit and function in your firearm.