Content Menu

● Introduction to RCBS 223 Reloading Dies

● Understanding Carbide Sizing Dies for 223

>> The Benefits of Full Length Sizing Dies for 223

● The RCBS Supreme Die Set for 223 Remington

>> 223 Remington Reloading Equipment: Beyond the Dies

● The Longevity of RCBS Carbide Dies

● Precision Reloading Tools for 223: Achieving Match-Grade Ammunition

>> RCBS Rifle Dies for 223: Versatility in Reloading

● High-Volume 223 Reloading: Efficiency and Quality

● RCBS 223 Die Maintenance: Ensuring Longevity and Performance

● Conclusion: The Value of RCBS 223 Carbide Dies in Precision Reloading

● Frequently Asked Questions

>> Q1: What are the main advantages of using RCBS carbide dies for 223 reloading?

>> Q2: Do I need to use case lube with RCBS carbide sizing dies for 223?

>> Q3: How often should I replace my RCBS 223 carbide dies?

>> Q4: Can RCBS 223 carbide dies be used for other similar cartridges?

>> Q5: What's the difference between full length sizing and neck sizing for 223 reloading?

Introduction to RCBS 223 Reloading Dies

For rifle enthusiasts and precision shooters, the world of reloading opens up a realm of possibilities for customization and performance enhancement. Among the essential tools in a reloader's arsenal, RCBS 223 reloading dies stand out as a pinnacle of quality and precision. These dies, especially the carbide variants, have revolutionized the reloading process for the popular .223 Remington cartridge, offering unparalleled consistency and longevity.

Understanding Carbide Sizing Dies for 223

At the heart of the RCBS 223 carbide dies set is the carbide sizing die. This component is crucial in the reloading process, responsible for resizing fired brass to its original dimensions. The use of carbide in these dies offers several advantages over traditional steel dies:

1. Reduced friction: Carbide's smooth surface minimizes friction during the sizing process, resulting in less wear on both the die and the brass cases.

2. Longevity: Carbide sizing dies for 223 are known for their exceptional durability, often outlasting their steel counterparts by a significant margin.

3. Consistency: The hardness of carbide ensures that the die maintains its dimensions over time, providing consistent results even after thousands of reloads.

The Benefits of Full Length Sizing Dies for 223

RCBS offers full length sizing dies as part of their 223 reloading die sets. Full length sizing is particularly important for semi-automatic rifles or when reloading brass fired from different firearms. The process ensures that:

- The entire case body is resized to factory specifications

- Proper headspace is maintained for reliable chambering and extraction

- Consistency is achieved across all reloaded rounds

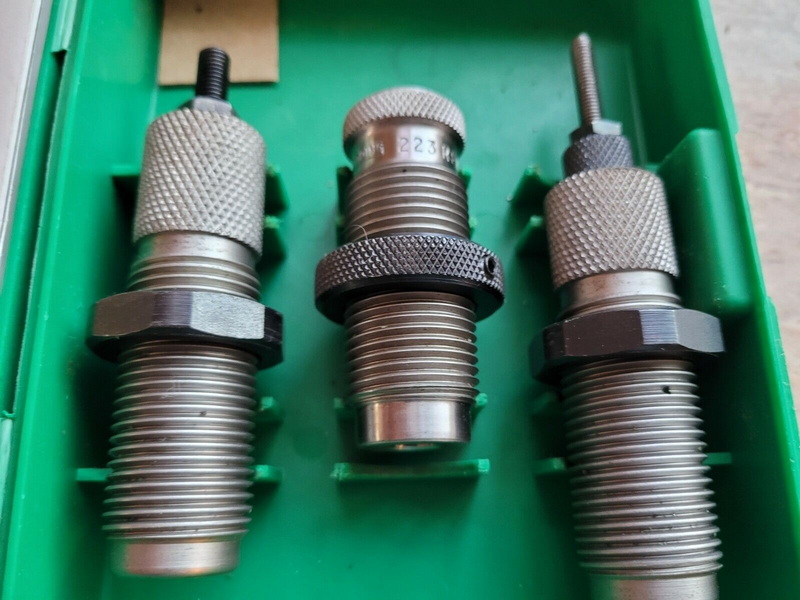

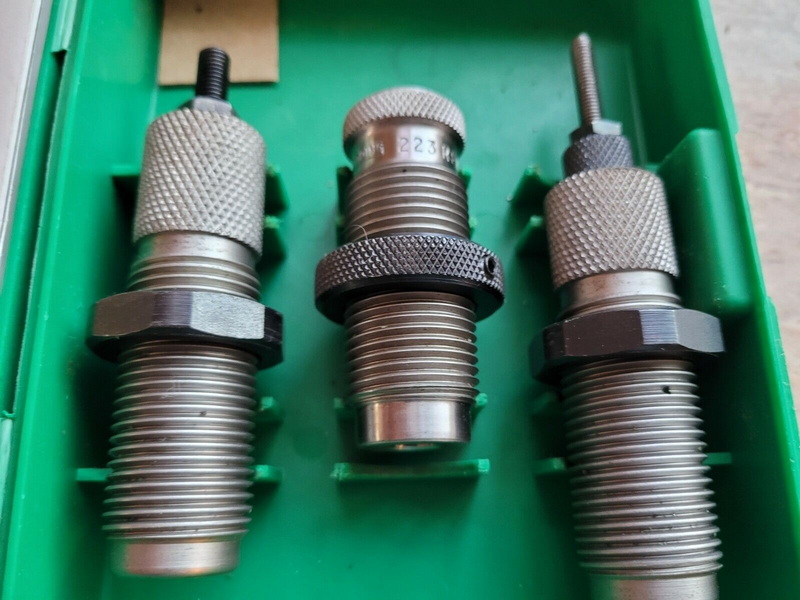

The RCBS Supreme Die Set for 223 Remington

For those seeking the pinnacle of reloading precision, the RCBS Supreme Die Set for 223 Remington is a game-changer. This premium set typically includes:

1. A full length sizing die with a carbide size button

2. A seating die for precise bullet placement

3. A taper crimp die for a secure bullet hold without deformation

The Supreme Die Set is designed for reloaders who demand the utmost in accuracy and consistency. The precision-machined components work in harmony to produce ammunition that rivals or exceeds factory-loaded cartridges in terms of accuracy and performance.

223 Remington Reloading Equipment: Beyond the Dies

While RCBS 223 carbide dies are central to the reloading process, they are part of a larger ecosystem of 223 Remington reloading equipment. To get the most out of your dies, consider complementing them with:

- A high-quality reloading press

- Precise measuring tools like calipers and micrometers

- A reliable powder scale and dispenser

- Case preparation tools (trimmers, deburring tools, etc.)

- Quality components (bullets, primers, and powder)

The Longevity of RCBS Carbide Dies

One of the most significant advantages of investing in RCBS carbide dies for 223 reloading is their exceptional longevity. The hardness of carbide ensures that these dies can withstand the rigors of high-volume reloading without significant wear. This durability translates to:

- Consistent performance over time

- Reduced need for replacement, saving money in the long run

- Ability to handle large reloading batches without degradation in quality

For high-volume reloaders, such as competitive shooters or those who frequently practice, the longevity of RCBS carbide dies is a crucial factor in maintaining efficiency and consistency in their reloading workflow.

Precision Reloading Tools for 223: Achieving Match-Grade Ammunition

The quest for match-grade ammunition drives many reloaders to seek out the best precision reloading tools for 223. RCBS carbide dies play a pivotal role in this pursuit, offering the precision necessary to create rounds that meet the exacting standards of competitive shooting. To achieve this level of accuracy:

1. Use the full length sizing die to ensure proper case dimensions

2. Employ the seating die to achieve consistent bullet seating depths

3. Utilize the taper crimp die for a secure hold without compromising accuracy

By combining these precision tools with careful load development and quality components, reloaders can produce ammunition that rivals or exceeds the performance of premium factory loads.

RCBS Rifle Dies for 223: Versatility in Reloading

RCBS rifle dies for 223 are not limited to carbide options. The company offers a range of dies to suit different reloading needs and preferences:

- Standard steel dies for general reloading

- Small base dies for semi-automatic rifles

- Neck sizing dies for bolt-action rifles

- Competition seating dies for ultimate precision

This versatility allows reloaders to choose the right tools for their specific firearms and reloading goals, whether it's high-volume plinking ammunition or precision loads for long-range shooting.

High-Volume 223 Reloading: Efficiency and Quality

For those engaged in high-volume 223 reloading, efficiency is key. RCBS carbide dies excel in this area, offering several advantages:

1. Reduced need for case lubrication, speeding up the reloading process

2. Consistent sizing, even after thousands of rounds

3. Less frequent die maintenance and replacement

To maximize efficiency in high-volume reloading:

- Consider a progressive reloading press for increased output

- Implement a streamlined case preparation process

- Use case feeders and other automation tools where possible

- Maintain detailed records to quickly replicate successful loads

RCBS 223 Die Maintenance: Ensuring Longevity and Performance

While RCBS carbide dies are known for their durability, proper maintenance is still essential to ensure optimal performance and longevity. Here are some tips for RCBS 223 die maintenance:

1. Clean dies regularly with a solvent to remove buildup of brass and lubricant

2. Inspect dies for signs of wear or damage

3. Apply a light coat of gun oil to prevent rust on non-carbide parts

4. Store dies in their original case or a dedicated die box to protect from dust and damage

5. Periodically check and adjust die settings to maintain consistency

By following these maintenance practices, reloaders can ensure that their RCBS 223 carbide dies continue to perform at their best for years to come.

Conclusion: The Value of RCBS 223 Carbide Dies in Precision Reloading

RCBS 223 carbide dies represent a significant investment in the pursuit of reloading excellence. Their precision, durability, and consistency make them an invaluable tool for both novice and experienced reloaders alike. Whether you're loading for competitive shooting, hunting, or simply enjoy the craft of creating your own ammunition, these dies provide the foundation for producing high-quality 223 Remington cartridges.

By understanding the nuances of full length sizing, leveraging the benefits of carbide technology, and implementing proper maintenance practices, reloaders can unlock the full potential of their RCBS 223 carbide dies. The result is not just ammunition, but a tailored shooting experience that meets the specific needs and preferences of the individual shooter.

As the world of firearms and ammunition continues to evolve, RCBS remains at the forefront, continually refining and improving their reloading dies and equipment. For those serious about reloading the 223 Remington cartridge, RCBS carbide dies are more than just tools – they're a gateway to precision, consistency, and the satisfaction of creating match-grade ammunition in the comfort of your own reloading bench.

Frequently Asked Questions

Q1: What are the main advantages of using RCBS carbide dies for 223 reloading?

Answer: The main advantages of RCBS carbide dies for 223 reloading include reduced friction during sizing, exceptional durability and longevity, consistent performance over time, and the ability to handle high-volume reloading without significant wear. These dies also often require less case lubrication, which can speed up the reloading process.

Q2: Do I need to use case lube with RCBS carbide sizing dies for 223?

Answer: While carbide dies generally require less lubrication than standard steel dies, it's still recommended to use a light coat of case lube when sizing 223 cases. This helps to protect both the cases and the die, ensuring smooth operation and preventing stuck cases. However, you'll likely need less lube compared to non-carbide dies.

Q3: How often should I replace my RCBS 223 carbide dies?

Answer: RCBS carbide dies are known for their exceptional longevity. With proper maintenance and care, they can last for tens of thousands of reloads or more. There's no set replacement schedule – instead, monitor your dies for signs of wear or inconsistency in sized cases. Many reloaders report using their carbide dies for decades without needing replacement.

Q4: Can RCBS 223 carbide dies be used for other similar cartridges?

Answer: While RCBS 223 carbide dies are specifically designed for the .223 Remington cartridge, they can often be used for very similar cartridges like the 5.56x45mm NATO. However, it's crucial to verify compatibility and proper headspace before using these dies for any cartridge other than the one they're designed for. Always consult the manufacturer's recommendations and a reloading manual.

Q5: What's the difference between full length sizing and neck sizing for 223 reloading?

Answer: Full length sizing resizes the entire case body to factory specifications, ensuring proper chambering in any firearm. This is ideal for semi-automatic rifles or when using brass fired from different guns. Neck sizing only resizes the neck of the case, leaving the body unchanged. This can potentially increase brass life and accuracy in bolt-action rifles, but may cause chambering issues in semi-autos or when using brass fired from different firearms. RCBS carbide dies are typically used for full length sizing due to their durability and consistency.