Content Menu

● Introduction

● Understanding Lee Carbide Rifle Dies

● Types of Lee Carbide Rifle Dies

>> Sizing Dies

>> Bullet Seating Dies

>> Crimping Dies

● The Reloading Process with Lee Carbide Dies

>> Step-by-Step Guide to Reloading Ammunition

>> Common Mistakes to Avoid During Reloading

>> Best Practices for Maintaining Your Dies

● Advantages of Using Lee Carbide Dies

>> Durability and Longevity

>> Cost-Effectiveness Compared to Other Brands

>> Enhanced Accuracy and Consistency in Ammunition

● User Experiences and Testimonials

● Conclusion

● Frequently Asked Questions

>> Q1. What are the main benefits of using Lee Carbide Rifle Dies?

>> Q2. How do I properly maintain my Lee Carbide Dies?

>> Q3. Can I use Lee Carbide Dies for all types of rifle cartridges?

>> Q4. What should I do if my resized brass cases are still not chambering correctly?

>> Q5. Is reloading ammunition safe?

Introduction

Reloading ammunition is a rewarding and practical skill for firearm enthusiasts. It allows shooters to customize their loads for specific firearms, improve accuracy, and save money in the long run. Among the various tools available for reloading, Lee Carbide Rifle Dies stand out for their precision and durability. This guide will explore the features, benefits, and processes associated with Lee Carbide Rifle Dies, providing you with a comprehensive understanding of how to enhance your reloading experience.

Understanding Lee Carbide Rifle Dies

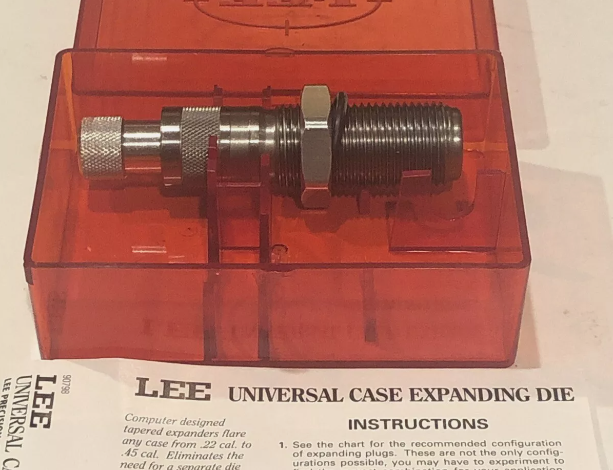

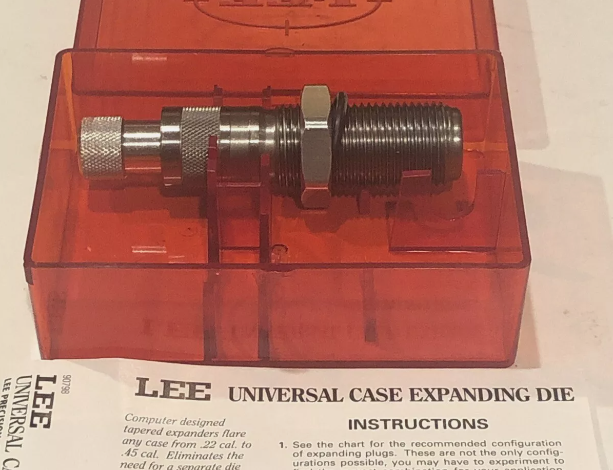

Lee Carbide Rifle Dies are specialized tools designed for reloading rifle cartridges. Unlike traditional steel dies, carbide dies are made from a harder material that offers several advantages. The primary benefit of carbide dies is their ability to resize brass cases without the need for lubrication. This not only speeds up the reloading process but also reduces the mess associated with using lubricants.

Carbide dies are particularly effective for resizing cases that have been fired in a chamber, ensuring they return to the correct dimensions for reliable chambering. Additionally, carbide dies tend to last longer than their steel counterparts, making them a cost-effective choice for serious reloaders.

Types of Lee Carbide Rifle Dies

Sizing Dies

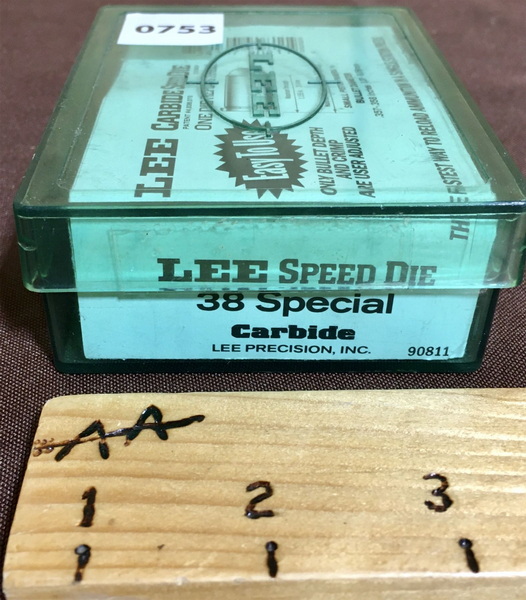

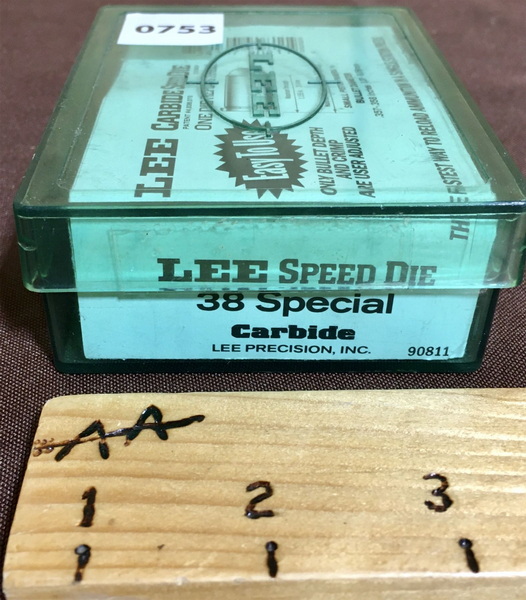

The sizing die is one of the most critical components in the reloading process. Its primary function is to resize the brass cases to ensure they fit properly in the chamber of your rifle. When a cartridge is fired, the brass expands to fit the chamber, and the sizing die brings it back to its original dimensions.

Using a sizing die effectively involves placing the brass case into the die and applying pressure with a reloading press. The carbide material allows for smooth resizing without lubrication, making the process quick and efficient.

Bullet Seating Dies

Once the brass cases are resized, the next step is to seat the bullet. The bullet seating die is designed to push the bullet into the case to the desired depth. Proper bullet seating is crucial for accuracy, as it affects the overall length of the cartridge and how it will perform when fired.

To use a bullet seating die, you will need to adjust the die to achieve the correct overall length for your specific load. This adjustment is essential for ensuring that the bullet is seated consistently across all cartridges.

Crimping Dies

Crimping is the final step in the reloading process, and it involves applying pressure to the case mouth to secure the bullet in place. A crimping die is used to create a slight indentation at the case mouth, which helps prevent the bullet from moving during handling and firing.

There are different crimping techniques, including taper crimp and roll crimp, depending on the type of bullet and cartridge being used. Understanding how to apply the correct crimp is vital for achieving reliable performance.

The Reloading Process with Lee Carbide Dies

Reloading ammunition with Lee Carbide Dies involves several steps, each critical to ensuring the quality and performance of the finished product.

Step-by-Step Guide to Reloading Ammunition

1. Gather Your Materials: Before starting, ensure you have all necessary components, including brass cases, bullets, powder, and primers.

2. Inspect the Brass: Check each brass case for signs of damage or wear. Discard any cases that are cracked or excessively worn.

3. Resize the Brass: Place the brass case into the sizing die and use a reloading press to resize it. Ensure the die is adjusted correctly for your specific cartridge.

4. Clean the Cases: After resizing, it's a good idea to clean the brass cases to remove any debris or residue.

5. Prime the Cases: Use a priming tool to insert new primers into the resized cases. This step is crucial for ensuring reliable ignition.

6. Measure and Add Powder: Using a powder scale, measure the appropriate amount of powder for your load. Carefully pour the powder into each case.

7. Seat the Bullets: Place a bullet on top of each charged case and use the bullet seating die to push it into the case to the desired depth.

8. Crimp the Cases: Finally, use the crimping die to secure the bullets in place, ensuring they are ready for firing.

Common Mistakes to Avoid During Reloading

Reloading can be a meticulous process, and several common mistakes can lead to poor performance or safety issues. Here are a few to watch out for:

- Overcharging: Adding too much powder can lead to dangerous pressures. Always double-check your measurements.

- Inconsistent Bullet Seating: Ensure that each bullet is seated to the same depth for consistent performance.

- Neglecting Case Inspection: Always inspect your brass cases for damage before reloading. Using damaged cases can lead to failures.

Best Practices for Maintaining Your Dies

To ensure the longevity and performance of your Lee Carbide Dies, follow these maintenance tips:

- Clean After Use: After each reloading session, clean your dies to remove any residue or debris.

- Store Properly: Keep your dies in a protective case to prevent damage and contamination.

- Check for Wear: Regularly inspect your dies for signs of wear or damage, and replace them as necessary.

Advantages of Using Lee Carbide Dies

Durability and Longevity

One of the standout features of Lee Carbide Dies is their durability. The carbide material is resistant to wear and tear, allowing these dies to maintain their precision over time. This longevity means that reloaders can rely on their Lee dies for many years, making them a worthwhile investment.

Cost-Effectiveness Compared to Other Brands

While some reloading dies can be quite expensive, Lee Carbide Dies offer a cost-effective solution without sacrificing quality. Many reloaders find that they can achieve excellent results with Lee dies at a fraction of the cost of other brands.

Enhanced Accuracy and Consistency in Ammunition

Using Lee Carbide Dies can lead to improved accuracy and consistency in your ammunition. The precision engineering of these dies ensures that each cartridge is resized and loaded uniformly, which is crucial for achieving tight groupings on the range.

User Experiences and Testimonials

Many seasoned reloaders have shared their positive experiences with Lee Carbide Rifle Dies. Users often highlight the ease of use and the quality of the finished ammunition. Testimonials frequently mention how the carbide dies have improved their reloading efficiency and the overall performance of their firearms.

For example, one user noted that switching to Lee Carbide Dies significantly reduced the time spent on reloading, allowing them to focus more on shooting. Another user praised the accuracy of their reloads, stating that they achieved tighter groupings than ever before.

Conclusion

Lee Carbide Rifle Dies are an essential tool for anyone serious about reloading ammunition. Their durability, cost-effectiveness, and ability to enhance accuracy make them a top choice among reloaders. By understanding the different types of dies and the reloading process, you can improve your skills and enjoy the many benefits of reloading your own ammunition.

As you embark on your reloading journey, remember to follow best practices, maintain your equipment, and continually seek to improve your techniques. With the right tools and knowledge, you can create high-quality ammunition tailored to your specific needs.

Frequently Asked Questions

Q1. What are the main benefits of using Lee Carbide Rifle Dies?

Lee Carbide Rifle Dies offer several benefits, including durability, cost-effectiveness, and the ability to resize brass without lubrication. They also enhance the accuracy and consistency of your ammunition.

Q2. How do I properly maintain my Lee Carbide Dies?

To maintain your Lee Carbide Dies, clean them after each use, store them in a protective case, and regularly inspect them for signs of wear or damage.

Q3. Can I use Lee Carbide Dies for all types of rifle cartridges?

Lee Carbide Dies are available for a wide range of rifle cartridges. However, it's essential to choose the correct die set for your specific cartridge to ensure optimal performance.

Q4. What should I do if my resized brass cases are still not chambering correctly?

If your resized brass cases are not chambering correctly, check for any signs of damage or excessive wear. You may also need to adjust your sizing die to ensure it is set correctly for your specific cartridge.

Q5. Is reloading ammunition safe?

When done correctly, reloading ammunition can be safe. It's crucial to follow proper procedures, use reliable components, and double-check measurements to avoid dangerous situations. Always prioritize safety and consult reputable resources for guidance.