Content Menu

● Introduction

● Understanding Composite Decking

● Why Choose Tungsten Carbide Tip Blades?

>> Types of Tungsten Carbide Tip Blades

>> Recommended Specifications

● How to Cut Composite Decking with Tungsten Carbide Tip Blades

>> Step-by-Step Guide

>> Tips for Optimal Cutting

● Addressing Common Challenges

● Alternative Blade Options

● Conclusion

● FAQ

>> 1. Can I use regular wood-cutting blades on composite decking?

>> 2. How do I know when my blade needs replacing?

>> 3. Is it necessary to sand edges after cutting?

>> 4. Can I cut composite decking with a hand saw?

>> 5. What maintenance do tungsten carbide blades require?

● Citations:

Introduction

When it comes to installing or maintaining composite decking, achieving clean, precise cuts is paramount. The choice of blade plays a crucial role in this process. Tungsten carbide tip blades have emerged as a popular and effective solution for cutting composite decking due to their durability, cutting efficiency, and ability to deliver smooth, professional results. This comprehensive article delves into whether tungsten carbide tip blades are indeed the optimal choice for cutting composite decking, examining their specific advantages, the recommended types, crucial considerations, and best practices. We aim to provide you with a thorough understanding to make informed decisions for your decking projects.

Understanding Composite Decking

Composite decking has revolutionized outdoor construction, offering a compelling alternative to traditional wood decking. It's crafted from a blend of wood fibers and recycled plastic, creating a material that boasts a unique set of properties:

- Durability: Composite decking exhibits exceptional resistance to rot, splintering, warping, and insect damage, ensuring a long-lasting and visually appealing surface.

- Low Maintenance: Unlike wood, composite decking requires minimal upkeep, eliminating the need for frequent staining, sealing, or painting. Regular cleaning is typically sufficient to maintain its appearance.

- Aesthetic Appeal: Available in a wide array of colors, textures, and finishes, composite decking can mimic the natural look of wood while offering greater design flexibility.

- Eco-Friendliness: Often made from recycled materials, composite decking contributes to environmental sustainability by reducing waste and conserving natural resources.

However, the unique composition of composite materials necessitates specialized cutting techniques and tools to achieve clean, accurate cuts without damaging the material.

Why Choose Tungsten Carbide Tip Blades?

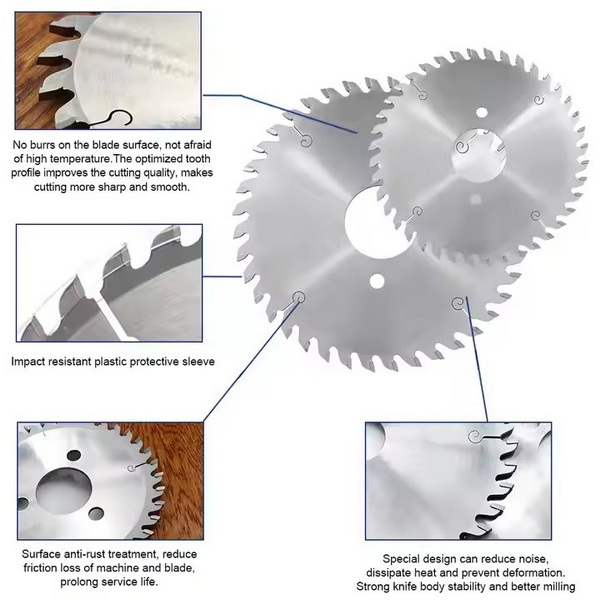

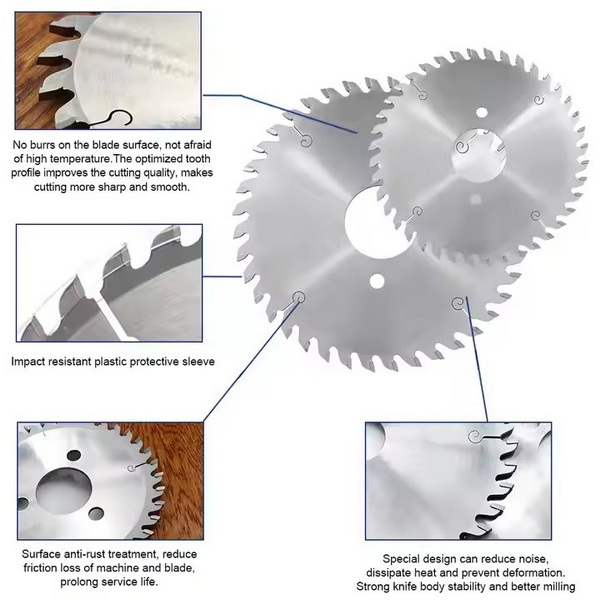

Tungsten carbide tip blades are engineered for high-performance cutting applications, offering superior durability and precision. Here's why they are particularly well-suited for cutting composite decking:

- Longevity: Tungsten carbide is renowned for its exceptional hardness and wear resistance. This allows the blade to maintain its sharpness for significantly longer than standard steel blades, reducing the need for frequent replacements.

- Clean Cuts: The specialized design of tungsten carbide blades minimizes chipping, splintering, and tear-out, which are common issues when cutting composite materials with less suitable blades. The result is a clean, professional-looking edge.

- Heat Resistance: These blades are designed to dissipate heat efficiently, preventing excessive buildup during cutting. This is crucial when working with composite materials, as excessive heat can cause melting, deformation, or discoloration.

- Versatility: Tungsten carbide tip blades can be used with various types of saws, including circular saws, miter saws, and table saws, providing flexibility for different cutting tasks.

Types of Tungsten Carbide Tip Blades

When selecting a tungsten carbide tip blade for cutting composite decking, it's essential to consider the type of saw you'll be using and the specific cutting requirements of your project. Here are some of the most common types of blades:

1. Circular Saw Blades: Ideal for making straight cuts in decking boards. These blades typically range in size from 7-1/4 inches to 12 inches and feature tooth counts between 40 and 80.

2. Miter Saw Blades: Perfect for making precise angled cuts, such as those required for corners and edges of decking. Look for fine-tooth blades that deliver smooth, clean finishes.

3. Table Saw Blades: Suitable for ripping decking boards to width or creating grooves. Choose a blade with a flat top grind to minimize tear-out.

4. Jigsaw Blades: Useful for making curved or intricate cuts. Opt for high-performance options like Diablo's tungsten carbide jigsaw blades, which offer exceptional durability and precision.

Recommended Specifications

To ensure optimal performance and longevity, pay close attention to these specifications when selecting a tungsten carbide blade for composite decking:

| Specification | Recommended Value |

| Blade Material | Tungsten Carbide |

| Tooth Count | 40 - 80 teeth |

| Blade Size | 7-1/4" to 12" |

| Kerf Width | Slim kerf (0.090" - 0.145") |

| Hook Angle | 5° to 15° |

| Grind Type | ATB (Alternate Top Bevel) |

How to Cut Composite Decking with Tungsten Carbide Tip Blades

Cutting composite decking effectively requires a combination of the right tools, techniques, and safety precautions. Here's a step-by-step guide to help you achieve professional results:

Step-by-Step Guide

1. Gather Tools and Materials:

- Tungsten carbide tip blade (appropriate for your saw type)

- Circular saw, miter saw, or table saw

- Measuring tape

- Straight edge or square

- Clamps (optional)

- Safety goggles

- Hearing protection

- Dust mask

2. Prepare Your Work Area:

- Ensure your work area is well-ventilated, clean, and free from obstructions.

- Set up a stable work surface or saw stand to support the decking boards during cutting.

3. Measure and Mark:

- Accurately measure the desired length of the decking board using a measuring tape.

- Use a straight edge or square to draw a precise cutting line across the board.

- Double-check your measurements to ensure accuracy.

4. Set Up Your Saw:

- Install the tungsten carbide blade according to the saw manufacturer's instructions.

- Adjust the saw's blade depth so that the blade extends slightly beyond the thickness of the decking board.

- Ensure that the blade is properly aligned and secured.

5. Secure the Board:

- If necessary, use clamps to firmly secure the decking board to the work surface or saw stand.

- This will prevent movement during cutting, ensuring a clean and accurate cut.

6. Make the Cut:

- Put on your safety goggles, hearing protection, and dust mask.

- Start the saw and allow it to reach full speed before making contact with the decking board.

- Use a slow, steady, and controlled motion while guiding the saw along the marked cutting line.

- Avoid forcing the saw or applying excessive pressure, as this can cause the blade to bind or kickback.

- Let the blade do the work.

7. Finish Up:

- After completing the cut, carefully inspect the edges for any rough spots, splinters, or tear-out.

- Use sandpaper or a file to smooth any rough edges and create a clean, professional finish.

Tips for Optimal Cutting

- Always wear safety goggles, hearing protection, and a dust mask when operating power tools.

- Ensure your workspace is well-lit and free from distractions.

- Use a sharp blade to avoid splintering and ensure clean cuts.

- Cut slowly and steadily to prevent overheating and melting of the composite material.

- Support the decking board close to the cutting line to prevent flexing and vibration.

- Use a vacuum or dust collector to remove sawdust and debris from your work area.

- Regularly inspect the blade for wear and replace it as needed.

- Consider using a lubricant or cutting fluid to reduce friction and heat buildup.

- Practice on scrap pieces of composite decking before cutting your final pieces.

Addressing Common Challenges

While tungsten carbide tip blades offer significant advantages, some challenges may arise when cutting composite decking. Here's how to address them:

- Melting: To prevent melting, use a blade with a high tooth count and cut at a slow, steady pace. Avoid applying excessive pressure.

- Chipping: Use a sharp blade and support the decking board close to the cutting line. Consider using a backer board to prevent tear-out.

- Blade Binding: Ensure the blade is properly aligned and that the decking board is adequately supported. Avoid forcing the saw or applying excessive pressure.

Alternative Blade Options

While tungsten carbide tip blades are generally recommended for cutting composite decking, other blade options may be suitable in certain situations:

- Diamond-Tipped Blades: Offer exceptional durability and are ideal for cutting abrasive materials like composite decking.

- High-Speed Steel (HSS) Blades: Can be used for cutting composite decking, but they may not last as long as tungsten carbide or diamond-tipped blades.

Conclusion

In conclusion, tungsten carbide tip blades are an excellent choice for cutting composite decking due to their exceptional durability, precision, and ability to deliver clean, professional cuts. By carefully selecting the right type of blade, following proper cutting techniques, and taking necessary safety precautions, you can achieve outstanding results in your decking projects. While other blade options exist, tungsten carbide remains a top choice for its balance of performance, longevity, and cost-effectiveness.

FAQ

1. Can I use regular wood-cutting blades on composite decking?

Using regular wood-cutting blades may lead to chipping, splintering, and rough edges. It is generally recommended to use tungsten carbide tip blades specifically designed for composite materials to ensure clean and accurate cuts.

2. How do I know when my blade needs replacing?

Signs that your blade needs replacing include excessive heat during cuts, visible wear on teeth, a decrease in cutting efficiency, or producing rough edges on cuts. Regular inspection of your blades is essential for maintaining optimal performance.

3. Is it necessary to sand edges after cutting?

While not always necessary, sanding edges after cutting can help achieve a smoother finish and reduce the likelihood of splintering. This is particularly important for creating a professional-looking result.

4. Can I cut composite decking with a hand saw?

Yes, you can cut composite decking with a hand saw, but it will require more effort and precision. Using power tools with tungsten carbide blades will provide cleaner cuts more efficiently and with greater accuracy than hand saws.

5. What maintenance do tungsten carbide blades require?

To prolong the life and performance of your tungsten carbide blades, keep them clean from debris after each use and store them in a dry place. Regularly inspect them for any signs of damage or wear, and sharpen or replace them as needed.

Citations:

[1] https://www.diablotools.com.au/Product/Product/AU2608F02245

[2] https://biform.co.nz/products-services/accessories/

[3] https://www.cnblogs.com/luohenyueji/p/16990846.html

[4] https://www.greenzone-wpc.com/info/what-blade-to-cut-composite-decking-97634833.html

[5] https://www.lowes.com/pl/power-tool-accessories/saw-blades/composite-decking/4294607793-1190424609

[6] https://www.csulb.edu/sites/default/files/document/2019_mini_manuscript.pdf

[7] https://www.moistureshield.com/about/blog/how-to-cut-composite-decking/

[8] https://biform.co.nz/resources/online-store/show/product-03/

[9] https://www.lowes.com/pl/power-tool-accessories/saw-blades/circular-saw-blades/composite-decking/4294607791-1190424609