Content Menu

● The Nature of Tungsten Carbide

● Rust Resistance of Tungsten Carbide

● Properties Contributing to Corrosion Resistance

● Corrosion Behavior of Tungsten Carbide

>> High-Temperature Oxidation

>> Acid Resistance

>> Reaction with Halogens

● Factors Affecting Corrosion Resistance

>> 1. Alloying Elements

>> 2. Environmental Conditions

>> 3. Extreme Heat

>> 4. Impurities

● Applications Leveraging Tungsten Carbide's Corrosion Resistance

● Comparison with Other Materials

● Maintenance and Care

● Future Developments

● Conclusion

● FAQ

>> 1. Can tungsten carbide jewelry be worn in water?

>> 2. How does the hardness of tungsten carbide compare to diamond?

>> 3. Is tungsten carbide magnetic?

>> 4. Can tungsten carbide be recycled?

>> 5. Does tungsten carbide conduct electricity?

● Citations:

Tungsten carbide is a remarkable material known for its exceptional hardness, durability, and resistance to wear. One of the most common questions about this versatile compound is whether it rusts. To answer this question and explore the properties of tungsten carbide in depth, let's delve into its composition, characteristics, and applications.

The Nature of Tungsten Carbide

Tungsten carbide (WC) is a chemical compound consisting of equal parts of tungsten and carbon atoms[2]. It is not a metal alloy but rather a product of powder metallurgy, where very fine grains of tungsten and carbon are mixed and fused under high temperature and pressure[9].

Rust Resistance of Tungsten Carbide

The short answer to whether tungsten carbide rusts is no, it does not rust in the traditional sense[1]. Rust is a term specifically used for the corrosion of iron and its alloys, such as steel, which occurs in the presence of moisture and oxygen. Since tungsten carbide does not contain iron, it cannot rust in the same way that steel does[1].

However, it's important to note that while tungsten carbide doesn't rust, it can experience other forms of corrosion or oxidation under certain conditions[3].

Properties Contributing to Corrosion Resistance

Several properties of tungsten carbide contribute to its excellent resistance to corrosion:

1. Chemical Stability: Tungsten carbide is an extremely stable substance that does not oxidize at normal temperatures in air[3].

2. Dense Crystal Structure: It forms a hexagonal crystal structure, which is very dense and resistant to chemical attack[3].

3. High Melting Point: With a melting point of 2,870°C (5,200°F), tungsten carbide remains stable even under extreme conditions[6].

4. Protective Oxide Layer: When exposed to air, tungsten forms a very stable oxide layer that acts as a shield, protecting the underlying material from further oxidation[1].

Corrosion Behavior of Tungsten Carbide

While tungsten carbide doesn't rust, it's not entirely immune to all forms of chemical attack. Here are some conditions under which tungsten carbide may experience corrosion or oxidation:

High-Temperature Oxidation

Oxidation of tungsten carbide begins at temperatures between 500–600°C (773–873 K)[2]. When heated to these temperatures in an oxygen-containing atmosphere, it reacts to form tungsten trioxide (WO₃)[3].

Acid Resistance

Tungsten carbide is highly resistant to most acids. It does not dissolve in water, hydrochloric acid, or sulfuric acid. However, it can be attacked by a mixture of hydrofluoric acid and nitric acid (HF/HNO₃) above room temperature[2].

Reaction with Halogens

Tungsten carbide reacts with fluorine gas at room temperature and with chlorine at temperatures above 400°C (673 K)[2].

Factors Affecting Corrosion Resistance

While pure tungsten carbide is highly resistant to corrosion, several factors can influence its corrosion behavior:

1. Alloying Elements

When tungsten is alloyed with other metals that are susceptible to rusting, the resulting alloy may be more prone to oxidation and tarnishing[5].

2. Environmental Conditions

Prolonged exposure to environments with high moisture and oxygen content may facilitate corrosion in tungsten carbide alloys[5].

3. Extreme Heat

At temperatures between 600°C to 800°C, pure tungsten may begin to oxidize and tarnish[5].

4. Impurities

If tungsten carbide contains impurities such as iron, these impurities may rust when exposed to water and oxygen[5].

Applications Leveraging Tungsten Carbide's Corrosion Resistance

The exceptional corrosion resistance of tungsten carbide makes it an ideal material for various applications:

1. Jewelry: Tungsten carbide rings are popular due to their durability and resistance to tarnishing[5].

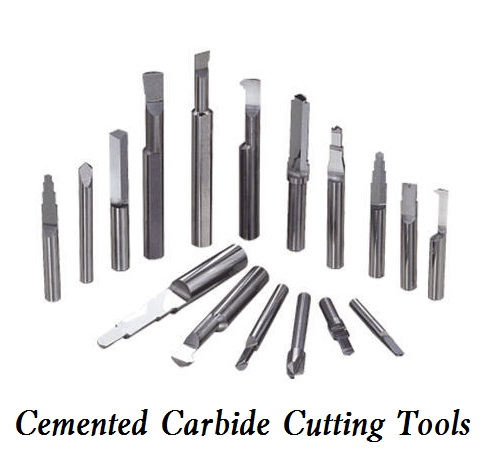

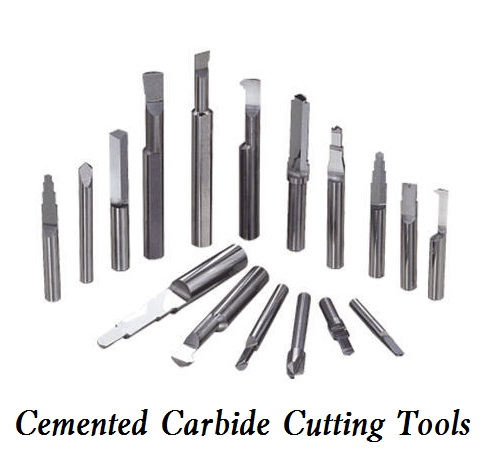

2. Cutting Tools: Its ability to maintain structural integrity at high temperatures makes it perfect for cutting tools used in high-speed, high-temperature environments[3].

3. Industrial Components: Tungsten carbide is used in parts that must withstand various forms of wear, including sliding erosion and corrosion[8].

4. Aerospace and Oil Drilling: Its durability and corrosion resistance make it valuable in demanding environments like aerospace turbines and oil drilling equipment[4].

5. Electronics: Tungsten carbide is used in X-ray tubes and electrodes due to its stability and conductivity[5].

Comparison with Other Materials

To better understand the corrosion resistance of tungsten carbide, let's compare it with some other common materials:

| Material | Corrosion Resistance | Hardness (Mohs scale) | Melting Point (°C) |

| Tungsten Carbide | Excellent | 9.0-9.5 | 2,870 |

| Steel | Poor (rusts easily) | 4-4.5 | 1,370-1,530 |

| Titanium | Excellent | 6.0 | 1,668 |

| Aluminum | Good | 2.5-3.0 | 660 |

As we can see, tungsten carbide outperforms many common materials in terms of corrosion resistance and hardness, while also having an exceptionally high melting point.

Maintenance and Care

Despite its excellent corrosion resistance, proper care can help maintain the appearance and integrity of tungsten carbide items:

1. Regular Cleaning: Clean tungsten carbide items with mild soap and water to remove dirt and oils.

2. Avoid Harsh Chemicals: While resistant to many chemicals, it's best to avoid prolonged exposure to strong acids or bases.

3. Storage: Store tungsten carbide items in a dry place to minimize exposure to moisture.

4. Polishing: If tarnishing occurs, gentle polishing can often restore the original luster.

Future Developments

Research into tungsten carbide continues, with scientists and engineers working on:

1. Improving the manufacturing process to enhance purity and performance.

2. Developing new tungsten carbide composites with even better corrosion resistance.

3. Exploring new applications in emerging technologies, such as renewable energy and space exploration.

Conclusion

In conclusion, tungsten carbide does not rust in the traditional sense, as it contains no iron. Its exceptional resistance to corrosion, combined with its remarkable hardness and high-temperature stability, makes it an invaluable material in numerous industrial and consumer applications. While it can experience oxidation under extreme conditions, tungsten carbide remains one of the most durable and corrosion-resistant materials available.

As we continue to push the boundaries of material science, tungsten carbide stands as a testament to human ingenuity, providing solutions to challenges across various industries. Its unique properties ensure that it will remain a crucial material in our technological landscape for years to come.

FAQ

1. Can tungsten carbide jewelry be worn in water?

Yes, tungsten carbide jewelry can be safely worn in water. It does not rust or tarnish when exposed to water, making it ideal for everyday wear, including swimming and showering[5].

2. How does the hardness of tungsten carbide compare to diamond?

Tungsten carbide is extremely hard, ranking about 9.0–9.5 on the Mohs scale. While this makes it one of the hardest materials available, it is still softer than diamond, which ranks 10 on the Mohs scale[2].

3. Is tungsten carbide magnetic?

No, tungsten carbide is not magnetic. This property, combined with its corrosion resistance, makes it suitable for use in environments where magnetic materials could cause interference[4].

4. Can tungsten carbide be recycled?

Yes, tungsten carbide can be recycled. There are specialized processes for recovering and reprocessing tungsten carbide, particularly from industrial tools and components[2].

5. Does tungsten carbide conduct electricity?

Yes, tungsten carbide has a relatively low electrical resistivity of about 0.2 μΩ·m, which is comparable to some metals. This makes it useful in certain electrical applications[2].

Citations:

[1] https://www.boyiprototyping.com/materials-guide/does-tungsten-rust/

[2] https://en.wikipedia.org/wiki/Tungsten_carbide

[3] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[4] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[5] https://kdmfab.com/does-tungsten-rust/

[6] https://www.vedantu.com/chemistry/tungsten-carbide

[7] https://www.hpnonline.com/sterile-processing/article/55233008/tungsten-carbide-versus-villains-is-it-rust-or-corrosion

[8] http://www.tungsten-carbide.com.cn

[9] http://www.chinatungsten.com/Tungsten-Carbide/Properties-of-Tungsten-Carbide.html