Content Menu

● The Discovery of Tungsten

>> Properties of Tungsten

● The Development of Tungsten Carbide

>> The Science Behind Tungsten Carbide

● Could Tungsten Carbide Have Existed in the Middle Ages?

>> Natural Occurrence of Tungsten

>> Medieval Metallurgy

>> Theoretical Possibility

● The Importance of Scientific Progress

>> The Role of Industrial Revolution

● The Impact of Tungsten Carbide

>> Tungsten Carbide in Modern Industry

>> Environmental Considerations

● Conclusion

● FAQ

>> 1. What is tungsten carbide?

>> 2. When was tungsten first discovered?

>> 3. Could medieval alchemists have created tungsten carbide?

>> 4. What are the main uses of tungsten carbide today?

>> 5. How does tungsten carbide compare to other hard materials?

● Citations:

Tungsten carbide, a remarkable material known for its exceptional hardness and durability, has become an integral part of modern industry and technology. However, the question of whether this compound could have existed in the Middle Ages is an intriguing one that leads us to explore the fascinating history of tungsten, its discovery, and the development of tungsten carbide. This article will delve into the origins of tungsten, the scientific advancements that led to the creation of tungsten carbide, and the theoretical possibility of its existence in medieval times.

The Discovery of Tungsten

The story of tungsten begins long before its official discovery as an element. In the 16th century, tin miners in Saxony encountered a mineral that interfered with their tin extraction process. This mineral, which we now know as wolframite, was given names like "wolfert" and "wolfrahm" by the miners, reflecting their frustration with its presence.

However, it wasn't until the 18th century that tungsten began to be scientifically studied. In 1781, Swedish chemist Carl Wilhelm Scheele isolated tungstic acid from a mineral called scheelite. Scheele's work laid the foundation for the eventual discovery of tungsten as a distinct element.

The actual isolation of tungsten as a metal occurred in 1783, when Spanish brothers Fausto and Juan José Elhuyar reduced tungstic acid with charcoal, producing tungsten metal for the first time. This breakthrough marked the official discovery of tungsten as an element.

Properties of Tungsten

Tungsten, also known as wolfram, is a rare metal found naturally on Earth almost exclusively in chemical compounds. It has the highest melting point of all elements except carbon, and the second highest boiling point after rhenium. These properties, along with its strength and durability, make tungsten invaluable in many industrial applications.

The Development of Tungsten Carbide

While tungsten itself was discovered in the late 18th century, tungsten carbide wasn't developed until much later. The journey towards creating this remarkable compound began in the late 19th century with the work of French chemist Henri Moissan.

Moissan, who was actually attempting to create artificial diamonds, synthesized tungsten carbide for the first time. However, the material he produced was too brittle and porous to be used as an engineered material.

The real breakthrough in tungsten carbide development came in the 1920s. In 1923, the German company Osram Study Group filed a patent for a material combining the hardness of tungsten carbide with the toughness of cobalt. This invention marked the birth of cemented carbide, also known as hardmetal.

In 1927, Friedrich Krupp AG became the first company to market this new material as a tool material under the brand name WIDIA, which stands for "wie diamant" or "like diamond" in German.

The Science Behind Tungsten Carbide

Tungsten carbide (WC) is a chemical compound containing equal parts of tungsten and carbon atoms. Its unique properties stem from its crystal structure. In its most stable form, tungsten carbide has a simple hexagonal crystal structure, where layers of tungsten atoms alternate with layers of carbon atoms.

This structure gives tungsten carbide its extreme hardness - about 9-9.5 on the Mohs scale, compared to diamond at 10. It's this hardness, combined with its high compressive strength and wear resistance, that makes tungsten carbide so valuable in industrial applications.

Could Tungsten Carbide Have Existed in the Middle Ages?

Given this history, it's clear that tungsten carbide as we know it today did not exist in the Middle Ages. The compound requires not only the isolation of pure tungsten but also advanced metallurgical techniques that were not available until the 20th century. However, this doesn't mean that the raw materials for tungsten carbide didn't exist in medieval times.

Natural Occurrence of Tungsten

Tungsten does occur naturally in several minerals, primarily wolframite and scheelite. These minerals have been present in the Earth's crust for millions of years and were certainly present during the Middle Ages. In fact, medieval miners encountered wolframite, even if they didn't understand its composition or potential.

Medieval Metallurgy

While medieval metallurgists were skilled in working with many metals, including iron, copper, and tin, they lacked the scientific understanding and technological capabilities to isolate tungsten from its ores. The extraction of tungsten requires temperatures of around 1,000°C (1,832°F) and chemical processes that were unknown in medieval times.

Theoretical Possibility

From a purely theoretical standpoint, the elements necessary to form tungsten carbide – tungsten and carbon – did exist in the Middle Ages. Tungsten was present in its mineral forms, and carbon was readily available in materials like charcoal. However, the conditions required to combine these elements into tungsten carbide were far beyond the capabilities of medieval technology.

The Importance of Scientific Progress

The story of tungsten carbide illustrates the crucial role of scientific and technological progress in the development of new materials. Several key advancements were necessary before tungsten carbide could be created:

1. Understanding of Chemical Elements: The concept of chemical elements as we understand them today didn't exist in the Middle Ages. It wasn't until the work of scientists like Antoine Lavoisier in the 18th century that the modern understanding of elements began to take shape.

2. Isolation of Tungsten: The ability to isolate tungsten from its ores required advancements in chemistry and metallurgy that occurred in the 18th and 19th centuries.

3. High-Temperature Processing: Creating tungsten carbide requires temperatures and controlled conditions that were not achievable with medieval technology.

4. Understanding of Material Properties: The deliberate combination of tungsten carbide with cobalt to create a hard yet tough material required a deep understanding of material properties that didn't exist until the 20th century.

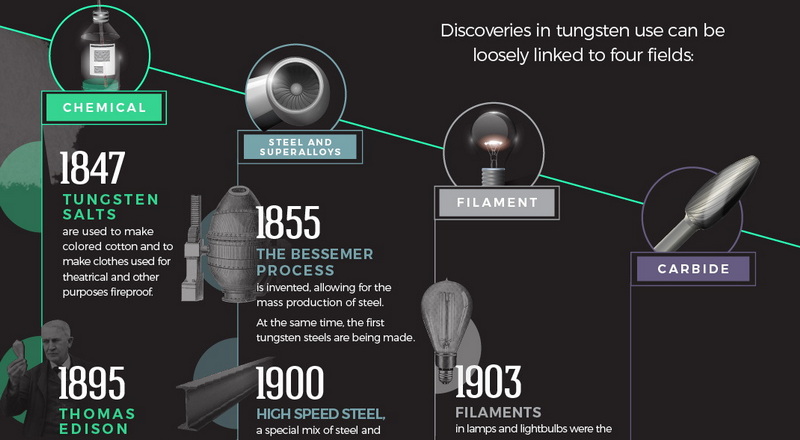

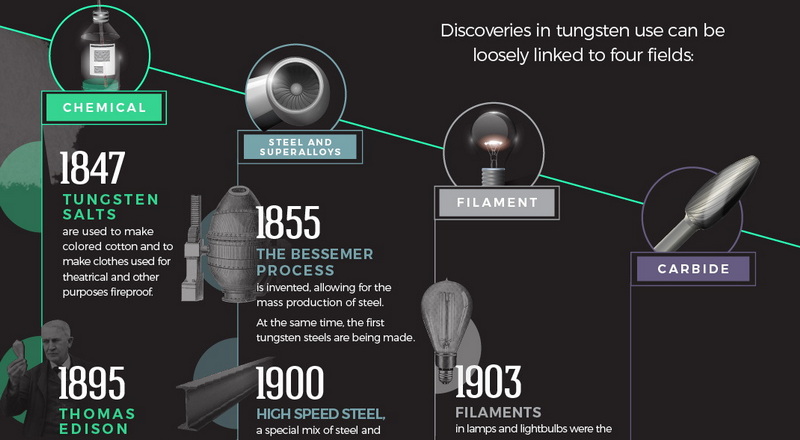

The Role of Industrial Revolution

The Industrial Revolution played a crucial role in paving the way for the development of tungsten carbide. The advancements in manufacturing processes, the increased demand for more efficient tools, and the rapid progress in scientific understanding all contributed to creating an environment where the development of new materials like tungsten carbide became possible.

The invention of the Bessemer process in the mid-19th century, for instance, revolutionized steel production and significantly advanced metallurgical capabilities. This progress in steel-making indirectly contributed to the eventual development of tungsten carbide by pushing the boundaries of what was possible in materials science.

The Impact of Tungsten Carbide

While tungsten carbide couldn't have existed in the Middle Ages, its development in the 20th century has had a profound impact on various industries. Some key applications include:

1. Cutting Tools: Tungsten carbide's hardness makes it ideal for cutting tools used in metalworking, mining, and construction.

2. Wear-Resistant Parts: Its resistance to wear makes tungsten carbide valuable for components in machinery that experience high levels of friction.

3. Armor-Piercing Ammunition: During World War II, tungsten carbide was used in armor-piercing projectiles.

4. Jewelry: Due to its scratch-resistant properties, tungsten carbide has become popular in jewelry making, particularly for men's wedding bands.

Tungsten Carbide in Modern Industry

The impact of tungsten carbide extends far beyond these applications. In the oil and gas industry, for example, tungsten carbide is used in drill bits, allowing for more efficient drilling operations. In the automotive industry, it's used in wear-resistant components and high-performance engine parts.

The aerospace industry also benefits from tungsten carbide's properties. It's used in jet engine components and in the production of rocket nozzles, where its ability to withstand high temperatures and resist wear is crucial.

Environmental Considerations

While tungsten carbide has brought numerous benefits to industry, its production and use also raise environmental concerns. The mining of tungsten ores can have significant environmental impacts, including habitat destruction and water pollution. Additionally, the energy-intensive process of producing tungsten carbide contributes to carbon emissions.

However, the durability and longevity of tungsten carbide products can offset some of these environmental costs. Tools and parts made from tungsten carbide last much longer than those made from other materials, reducing the need for frequent replacements and potentially lowering overall resource consumption.

Conclusion

While the raw materials for tungsten carbide – tungsten minerals and carbon – existed in the Middle Ages, the compound itself could not have existed during this period. The creation of tungsten carbide required scientific understanding, technological capabilities, and industrial processes that were not developed until the 20th century.

The journey from the first encounters with tungsten-bearing minerals by medieval miners to the development of tungsten carbide as a vital industrial material spans centuries of scientific and technological progress. This story serves as a testament to the power of human curiosity, scientific inquiry, and technological innovation.

As we continue to push the boundaries of materials science, we can only imagine what new compounds and materials might be developed in the future, potentially revolutionizing industries in ways we can't yet foresee. Just as tungsten carbide would have seemed like science fiction to a medieval blacksmith, the materials of the future may seem equally fantastical to us today.

FAQ

1. What is tungsten carbide?

Tungsten carbide is a chemical compound consisting of equal parts of tungsten and carbon atoms. It's known for its extreme hardness and wear resistance, making it valuable in various industrial applications.

2. When was tungsten first discovered?

Tungsten was first isolated as a distinct element in 1783 by Spanish brothers Fausto and Juan José Elhuyar, although its compounds had been studied earlier by Swedish chemist Carl Wilhelm Scheele in 1781.

3. Could medieval alchemists have created tungsten carbide?

No, medieval alchemists lacked the scientific understanding and technological capabilities to create tungsten carbide. The compound requires pure tungsten, which wasn't isolated until the 18th century, and advanced metallurgical techniques developed in the 20th century.

4. What are the main uses of tungsten carbide today?

Today, tungsten carbide is primarily used in cutting tools for metalworking, mining equipment, wear-resistant parts in various machinery, and in some types of jewelry.

5. How does tungsten carbide compare to other hard materials?

Tungsten carbide is one of the hardest man-made materials, second only to a few substances like diamond and cubic boron nitride. It's significantly harder than steel and retains its hardness at high temperatures, making it ideal for many industrial applications.

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten

[2] https://timelines.issarice.com/wiki/Timeline_of_tungsten

[3] https://www.itia.info/history-of-tungsten/

[4] https://www.tungstenmetalsgroup.com/blog-blog/tungsten-metals-unique-history-modern-applications

[5] https://almonty.com/tungsten-history/

[6] http://www.sputtering-targets.net/blog/discovery-and-development-of-tungsten-history/

[7] https://www.visualcapitalist.com/history-of-tungsten-worlds-strongest-metal/

[8] https://www.tungsten.com/blog/tungsten-detailed-history

[9] https://generalcarbide.com/pdf/General-Carbide-Designers-Guide-Tungsten-Carbide.pdf