Content Menu

● What is Tungsten Carbide?

>> Properties of Tungsten Carbide

>> Composition and Manufacturing

>> Applications of Tungsten Carbide

● The Concept of "Stretching" in Materials Science

>> Tensile Strength and Elongation

>> Ductility and Brittleness

>> Factors Affecting Stretchability

● Can Tungsten Carbide Be Stretched?

>> Hardness vs. Stretchability

>> Brittleness of Tungsten Carbide

>> Limited Plastic Deformation

>> Compressive Strength vs. Tensile Strength

>> Microstructure and Grain Boundaries

● Alternative Methods of Shaping Tungsten Carbide

>> Sintering

>> Grinding

>> Electric Discharge Machining (EDM)

>> High-Velocity Oxygen Fuel (HVOF) Coating

● Enhancing Ductility in Tungsten Carbide Composites

>> Addition of Ductile Binders

>> Nanomaterials and Composites

>> Surface Treatments

● Conclusion

● FAQ

>> 1. What makes tungsten carbide so hard?

>> 2. Can tungsten carbide rings be resized?

>> 3. Is tungsten carbide suitable for high-temperature applications?

>> 4. How does the addition of cobalt affect tungsten carbide's properties?

>> 5. What are the primary industries that use tungsten carbide?

● Citations:

Tungsten carbide (WC) is a chemical compound comprising tungsten and carbon atoms. It exists most commonly as a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, jewelry and more[1][7]. Tungsten carbide is approximately twice as stiff as steel, and is much denser than steel or titanium[5]. It is comparable to corundum in hardness and can only be polished and finished with abrasives of superior hardness such as cubic boron nitride and diamond powder[1].

Given these properties, the question of whether tungsten carbide can be stretched is an interesting one. This article delves into the properties of tungsten carbide, its applications, and ultimately, whether it can be stretched.

What is Tungsten Carbide?

Tungsten carbide is a compound, typically a powder, that can be compacted into various shapes through a process called sintering[8]. It's known for its exceptional hardness, strength, and resistance to wear and corrosion[7]. These properties make it an invaluable material in various industries[3][7][8].

Properties of Tungsten Carbide

Tungsten carbide possesses a unique combination of properties that make it suitable for demanding applications[5][8]:

- Hardness: Ranking between 9.0 and 9.5 on the Mohs scale, it approaches the hardness of diamond[1].

- Strength: It has very high compressive strength, higher than virtually all melted, cast, or forged metals and alloys[1][5]. Its ultimate tensile strength is 344 MPa[1].

- Rigidity: Tungsten carbide is significantly more rigid than steel and cast iron[5]. Its Young's modulus ranges from approximately 530 to 700 GPa[1].

- Wear Resistance: It wears up to 100 times longer than steel in abrasive conditions[5].

- Thermal Properties: Tungsten carbide has a high melting point of 2,870 °C and maintains its structural integrity at high temperatures[1][8]. It also demonstrates good thermal conductivity[1][5].

- Corrosion Resistance: Certain grades offer corrosion resistance comparable to noble metals[5].

Composition and Manufacturing

Tungsten carbide is composed of tungsten and carbon atoms in a hexagonal crystal structure[8]. The most common composition is about 94% tungsten and 6% carbon by weight, though this can be modified by adding metallic binders like cobalt or nickel to enhance certain properties[8]. The resulting composite, known as a cermet (ceramic-metallic composite), combines the hardness of the ceramic with the toughness of the metallic binder[8].

The manufacturing process involves carefully controlling particle size distributions and morphologies to optimize coating performance[8].

Applications of Tungsten Carbide

Tungsten carbide's properties make it useful across a range of industries[7][8]:

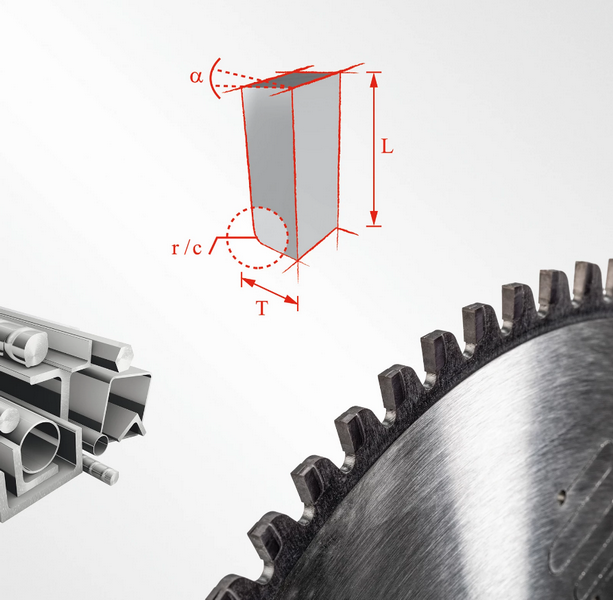

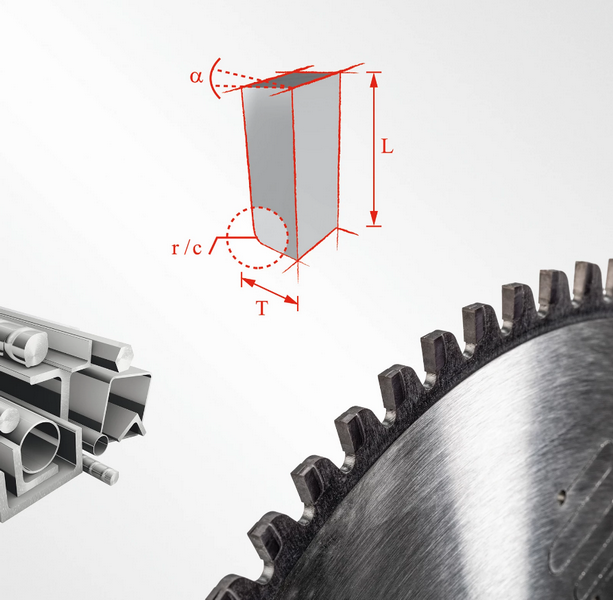

- Cutting Tools: Used in lathe tools and milling cutters for improved processing efficiency[3][7].

- Aerospace: Protects critical engine components from wear[7][8].

- Oil and Gas: Enhances the life of drilling equipment[8].

- Manufacturing: Applied to metal forming and processing tools[8].

- Mining and Drilling: Used in drill bits and mining tools due to its erosion resistance[7].

The Concept of "Stretching" in Materials Science

In materials science, "stretching" refers to the ability of a material to deform under tensile stress[3]. This property is often quantified by measuring a material's elongation or strain[3].

Tensile Strength and Elongation

- Tensile Strength: The maximum stress a material can withstand while being stretched before breaking[1].

- Elongation: The extent to which a material can be stretched before it fractures, expressed as a percentage of its original length[3].

Ductility and Brittleness

- Ductility: A material's ability to undergo significant plastic deformation under tensile stress before fracture[8]. Ductile materials can be drawn into wires or stretched into thin sheets[3].

- Brittleness: The tendency of a material to fracture with little or no plastic deformation[1]. Brittle materials break suddenly when subjected to stress[1].

Factors Affecting Stretchability

Several factors influence a material's ability to be stretched:

- Temperature: Higher temperatures can increase ductility in some materials, while lower temperatures can make them more brittle[5].

- Grain Size: Smaller grain sizes can enhance ductility by allowing more uniform deformation[8].

- Composition: Adding specific elements can alter the material's crystal structure and affect its ductility[8].

- Defects: The presence of micro-cracks or voids can reduce a material's ability to stretch[8].

Can Tungsten Carbide Be Stretched?

Given the properties of tungsten carbide, particularly its high hardness and brittleness, it is not easily stretched[1].

Hardness vs. Stretchability

Tungsten carbide's high hardness means it resists deformation[1]. Materials with high hardness tend to have low ductility, making them difficult to stretch without fracturing[4].

Brittleness of Tungsten Carbide

Tungsten carbide is inherently brittle, meaning it tends to fracture rather than deform plastically under tensile stress[1]. This brittleness is a limiting factor in its ability to be stretched[4].

Limited Plastic Deformation

Unlike ductile materials like steel or aluminum, tungsten carbide exhibits very little plastic deformation before fracture[5]. Plastic deformation is essential for stretching a material, as it allows the material to elongate without breaking[3].

Compressive Strength vs. Tensile Strength

While tungsten carbide has exceptionally high compressive strength, its tensile strength is significantly lower[1][5]. Stretching primarily involves tensile forces, making the material more susceptible to fracture[1].

Microstructure and Grain Boundaries

The microstructure of tungsten carbide, including grain size and the presence of binder phases like cobalt, affects its mechanical properties[8]. The brittleness of the η-carbides phases makes control of the carbon content in WC-Co cemented carbides important[1]. Abnormal grain growth in the sintering process can also affect performance[1].

Alternative Methods of Shaping Tungsten Carbide

While stretching may not be feasible, tungsten carbide can be shaped using alternative methods[3][7]:

Sintering

Tungsten carbide powder is compacted into a desired shape and then heated to a high temperature in a controlled atmosphere[8]. Sintering causes the particles to bond together, creating a solid, dense component[8].

Grinding

Tungsten carbide components can be ground to precise dimensions using abrasive materials like diamond or cubic boron nitride[1]. This method is used to achieve tight tolerances and smooth surface finishes[3].

Electric Discharge Machining (EDM)

EDM is a process that uses electrical sparks to erode the material[3]. It is suitable for creating complex shapes and intricate details in tungsten carbide components[3].

High-Velocity Oxygen Fuel (HVOF) Coating

Tungsten carbide coatings can be applied to other materials using the HVOF process[8]. This involves spraying molten or semi-molten particles onto a substrate at high velocity, creating a dense, wear-resistant layer[8].

Enhancing Ductility in Tungsten Carbide Composites

While pure tungsten carbide is not very ductile, researchers have explored methods to enhance the ductility of tungsten carbide composites[8].

Addition of Ductile Binders

Adding ductile metallic binders like cobalt or nickel can improve the overall toughness and ductility of tungsten carbide composites[8]. These binders help to absorb energy and reduce the likelihood of brittle fracture[8].

Nanomaterials and Composites

Incorporating nanomaterials or creating composite structures can also enhance ductility[8]. For example, dispersing oxide particles within the tungsten carbide matrix can refine the microstructure and improve mechanical properties[6].

Surface Treatments

Surface treatments like compressive residual stress induction can enhance the fatigue life and fracture resistance of tungsten carbide components[8]. These treatments help to prevent crack initiation and propagation[8].

Conclusion

Tungsten carbide, known for its exceptional hardness, strength, and wear resistance, is not easily stretched due to its inherent brittleness and limited plastic deformation. While pure tungsten carbide is challenging to stretch, alternative methods like sintering, grinding, EDM, and HVOF coating are employed to shape and apply this versatile material. Furthermore, research into enhancing ductility through the addition of ductile binders, nanomaterials, and surface treatments offers potential avenues for improving the stretchability of tungsten carbide composites.

FAQ

1. What makes tungsten carbide so hard?

Tungsten carbide's hardness comes from the strong covalent bonds between tungsten and carbon atoms in its crystal structure[1].

2. Can tungsten carbide rings be resized?

Due to its hardness, tungsten carbide rings cannot be resized in the same way as gold or silver rings[4].

3. Is tungsten carbide suitable for high-temperature applications?

Yes, tungsten carbide has a high melting point and maintains its structural integrity at high temperatures, making it suitable for applications in cutting tools and aerospace[1][7].

4. How does the addition of cobalt affect tungsten carbide's properties?

Adding cobalt as a binder enhances the toughness and ductility of tungsten carbide, improving its resistance to fracture[8].

5. What are the primary industries that use tungsten carbide?

Tungsten carbide is used extensively in cutting tools, aerospace, oil and gas, manufacturing, and mining industries due to its wear resistance and strength[7][8].

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://www.mdpi.com/1420-3049/30/1/84

[3] https://www.carbide-part.com/blog/applications-and-features/

[4] https://www.timelesstungsten.com/kb/can-i-resize-a-tungsten-ring/

[5] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[6] https://www.science.gov/topicpages/t/tungsten+dispersal+experiment.html

[7] https://www.carbide-part.com/blog/application-fields-and-characteristics-of-tungsten-carbide/

[8] https://www.linde-amt.com/resource-library/articles/tungsten-carbide