Content Menu

● Understanding Silicon Carbide

● Advantages of Silicon Carbide Bulletproof Plates

>> Lightweight and Durable

>> High Hardness and Impact Resistance

>> Corrosion Resistance

● Testing Methods for Multi-Hit Resistance

>> Ballistic Testing

>> Multi-Hit Testing

>> Environmental Testing

● Real-World Applications of Silicon Carbide Armor

>> Military Applications

>> Law Enforcement

>> Civilian Use

● Conclusion

● Related Questions

>> 1. What are the specific testing methods used to evaluate multi-hit resistance in silicon carbide plates?

>> 2. How does the cost of silicon carbide plates compare to other bulletproof materials?

>> 3. What are the potential applications of silicon carbide armor beyond personal protection?

>> 4. How does silicon carbide compare to other materials like Kevlar or steel in terms of performance?

>> 5. Are there any limitations to using silicon carbide in bulletproof plates?

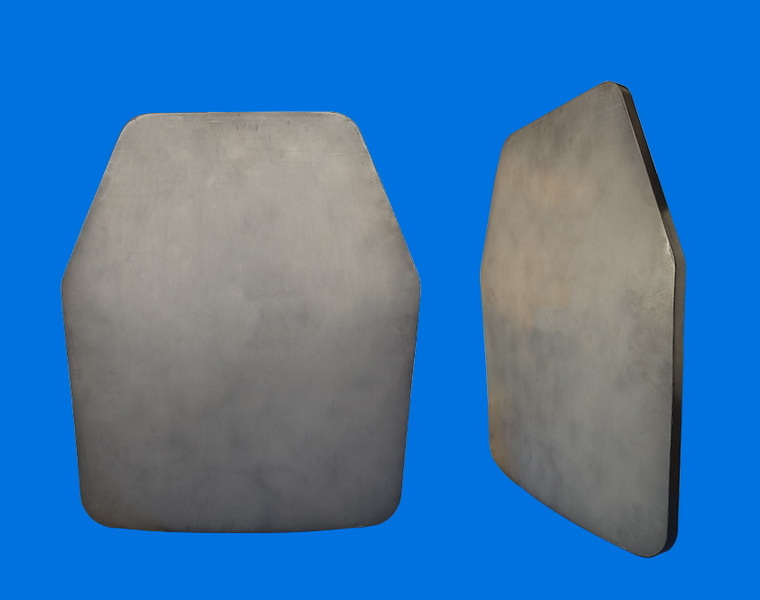

Silicon carbide (SiC) has emerged as a leading material in the production of bulletproof plates, particularly for military and law enforcement applications. Known for its exceptional hardness and lightweight properties, silicon carbide is increasingly being utilized in armor systems designed to withstand multiple hits. This article explores the capabilities of silicon carbide bulletproof plates, their advantages, testing methods, and real-world applications.

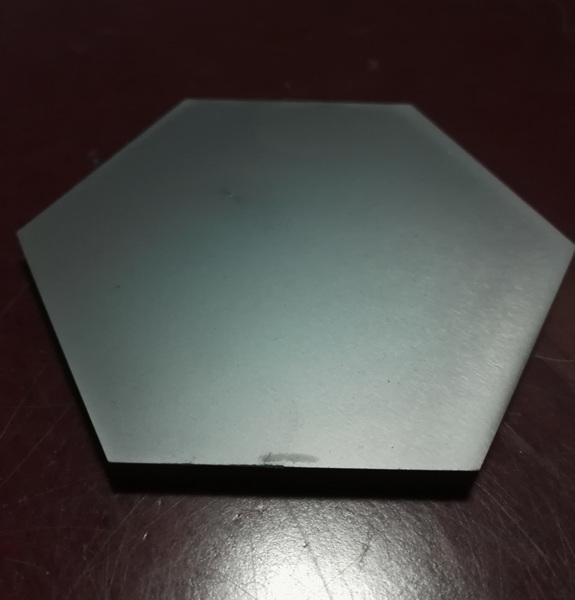

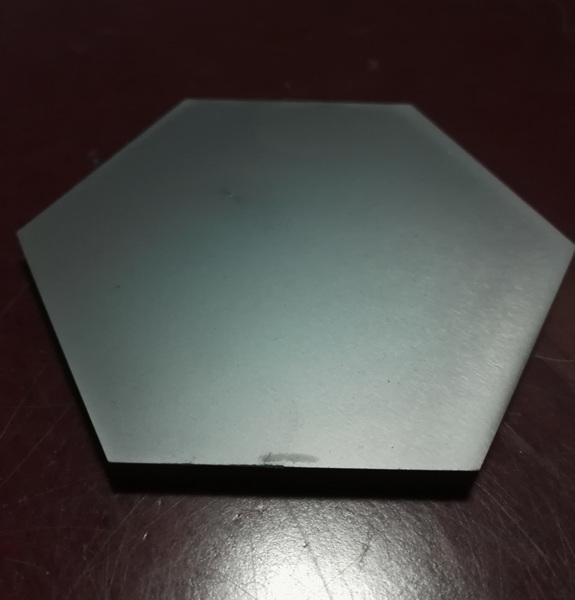

Understanding Silicon Carbide

Silicon carbide is a compound of silicon and carbon, known for its remarkable hardness and thermal stability. It is produced through a high-temperature process that combines silica sand and carbon. The resulting material is not only hard but also lightweight, making it an ideal candidate for ballistic protection.

The unique properties of silicon carbide allow it to absorb and dissipate energy effectively, which is crucial in armor applications. When a bullet strikes a silicon carbide plate, the material undergoes a transformation that helps to spread the impact force over a larger area, reducing the likelihood of penetration.

Advantages of Silicon Carbide Bulletproof Plates

Lightweight and Durable

One of the primary advantages of silicon carbide plates is their lightweight nature. Compared to traditional steel armor, silicon carbide offers similar or superior protection while significantly reducing the weight carried by the wearer. This is particularly important for military personnel and law enforcement officers who require mobility and agility in the field.

High Hardness and Impact Resistance

Silicon carbide is one of the hardest materials available, ranking just below diamond on the Mohs scale. This hardness translates into excellent impact resistance, allowing the plates to withstand multiple hits without compromising their structural integrity. The ability to endure repeated impacts is a critical factor in the effectiveness of body armor.

Corrosion Resistance

Another significant benefit of silicon carbide is its resistance to corrosion. Unlike metal-based armor, which can rust and degrade over time, silicon carbide maintains its protective qualities even in harsh environmental conditions. This durability ensures that the armor remains effective throughout its lifespan.

Testing Methods for Multi-Hit Resistance

To evaluate the performance of silicon carbide bulletproof plates, various testing methods are employed. These tests are designed to simulate real-world conditions and assess the armor's ability to withstand multiple hits.

Ballistic Testing

Ballistic testing is the most common method used to evaluate the effectiveness of bulletproof plates. During these tests, plates are subjected to a series of shots from different types of firearms and ammunition. The results are analyzed to determine the level of protection offered by the plates.

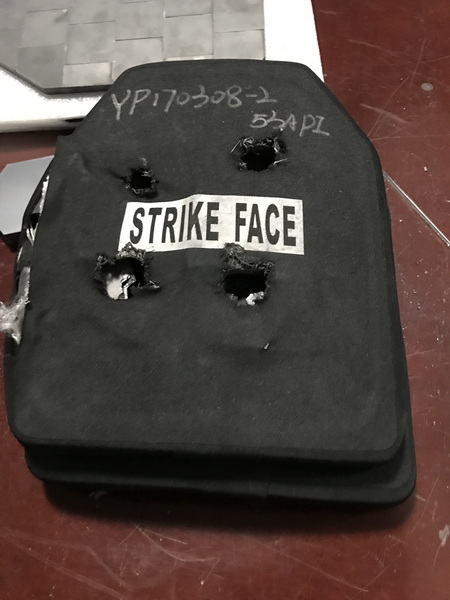

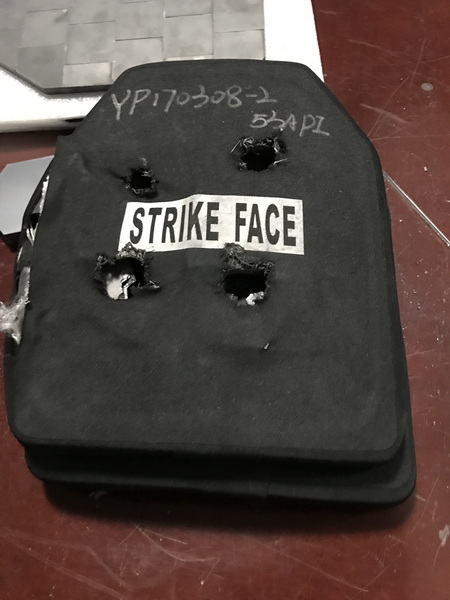

Multi-Hit Testing

Multi-hit testing specifically assesses the armor's ability to withstand consecutive impacts. In this testing scenario, multiple rounds are fired at the same location on the plate to evaluate whether it can maintain its protective capabilities after repeated hits. This is crucial for understanding how the armor will perform in real combat situations.

Environmental Testing

Environmental factors can significantly affect the performance of bulletproof plates. Therefore, environmental testing is conducted to evaluate how factors such as temperature, humidity, and exposure to chemicals impact the armor's effectiveness. This testing ensures that the plates will perform reliably in various conditions.

Real-World Applications of Silicon Carbide Armor

Silicon carbide bulletproof plates are utilized in a variety of applications, ranging from personal protection to military use.

Military Applications

In military settings, silicon carbide plates are commonly used in body armor systems for soldiers. The lightweight and durable nature of the material allows soldiers to carry additional equipment without being weighed down. Additionally, the ability to withstand multiple hits is crucial in combat scenarios where soldiers may face sustained fire.

Law Enforcement

Law enforcement agencies also utilize silicon carbide armor for officers in high-risk situations. The plates provide essential protection during confrontations with armed suspects, ensuring that officers can perform their duties with a higher level of safety.

Civilian Use

Beyond military and law enforcement applications, silicon carbide bulletproof plates are increasingly being adopted for civilian use. Individuals seeking personal protection, such as security personnel or private citizens in high-risk areas, can benefit from the lightweight and effective armor that silicon carbide provides.

Conclusion

Silicon carbide bulletproof plates represent a significant advancement in personal protection technology. Their lightweight, durable, and corrosion-resistant properties make them an ideal choice for military, law enforcement, and civilian applications. With rigorous testing methods ensuring their effectiveness, these plates can withstand multiple hits, providing users with the confidence and safety they need in high-risk situations.

Related Questions

1. What are the specific testing methods used to evaluate multi-hit resistance in silicon carbide plates?

The specific testing methods include ballistic testing, multi-hit testing, and environmental testing. These methods assess the armor's ability to withstand impacts and perform reliably under various conditions.

2. How does the cost of silicon carbide plates compare to other bulletproof materials?

Silicon carbide plates tend to be more expensive than traditional steel armor due to the complex manufacturing process. However, their lightweight and superior performance can justify the higher cost for many users.

3. What are the potential applications of silicon carbide armor beyond personal protection?

Beyond personal protection, silicon carbide armor can be used in vehicle armor, protective gear for security personnel, and even in industrial applications where impact resistance is crucial.

4. How does silicon carbide compare to other materials like Kevlar or steel in terms of performance?

Silicon carbide offers superior hardness and multi-hit resistance compared to steel and is lighter than both steel and Kevlar. However, Kevlar provides flexibility and is often used in soft armor applications.

5. Are there any limitations to using silicon carbide in bulletproof plates?

While silicon carbide is highly effective, it can be more brittle than other materials, which may lead to cracking under certain conditions. Additionally, the cost and weight, while advantageous, can be limiting factors for some applications.