Content Menu

● Introduction to Carbide Products

>> Properties of Tungsten Carbide

● Military Applications of Carbide Products

>> Ammunition and Armor-Piercing Rounds

>> Cutting Tools for Military Equipment

>> Firearm Components

>> Ordnance Components

>> Weapon Accessories

● Industrial Applications of Carbide Products

>> Pumps, Valves, and Compressors

>> Oil, Gas, and Petrochemical

>> Chemical and Pharmaceutical

>> Sheet Metal and Metal Packaging

>> Mining and Drilling

>> Construction and Building

>> Automotive

>> Aerospace

● Advancements and Innovations

>> Sustainability and Environmental Impact

>> Future Prospects

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary applications of tungsten carbide in the military?

>> 2. How does tungsten carbide benefit industrial applications?

>> 3. What makes tungsten carbide suitable for cutting tools?

>> 4. How is tungsten carbide used in mining and drilling?

>> 5. What are the advantages of using tungsten carbide in the chemical and pharmaceutical industries?

● Citations:

Carbide products manufacturers play a crucial role in supplying both military and industrial applications with high-performance materials. Tungsten carbide, in particular, is renowned for its exceptional hardness, density, and resistance to wear and corrosion, making it an ideal choice for a wide range of applications. This article explores the diverse roles of carbide products in military and industrial sectors, highlighting their significance and versatility.

Introduction to Carbide Products

Carbide products, especially those made from tungsten carbide, are engineered to meet the demanding needs of various industries. These materials are synthesized by combining tungsten and carbon, resulting in a compound that is harder than most metals and alloys. The manufacturing process involves sintering the tungsten carbide powder with a binder, typically cobalt, to create a robust and durable material known as cemented carbide.

Properties of Tungsten Carbide

- Hardness and Wear Resistance: Tungsten carbide is significantly harder than steel, making it ideal for cutting tools and wear-resistant components.

- Density and Strength: Its high density and compressive strength allow it to withstand extreme pressures and impacts.

- Corrosion Resistance: Certain grades of tungsten carbide offer corrosion resistance comparable to noble metals.

Military Applications of Carbide Products

In the military sector, carbide products manufacturers supply materials for various critical applications:

Ammunition and Armor-Piercing Rounds

Tungsten carbide is used in the production of armor-piercing rounds due to its exceptional hardness and density. These rounds are designed to penetrate heavy armor effectively, making them crucial in anti-tank and armor-piercing ammunition.

Cutting Tools for Military Equipment

The manufacturing of military equipment often involves materials that are difficult to machine, such as titanium and armor-grade steel. Tungsten carbide cutting tools are indispensable for shaping these materials due to their high hardness and resistance to wear.

Firearm Components

In firearms, tungsten carbide is used for parts that require robustness and durability, such as bolts, firing pins, and extractor claws. The material's wear resistance ensures these components can endure repeated use, enhancing the firearm's reliability and lifespan.

Ordnance Components

For ordnance applications, tungsten carbide is used in critical parts like bearings, bushings, and wear plates. These components must withstand high impacts and extreme pressures, and tungsten carbide's toughness and strength make it an excellent choice.

Weapon Accessories

The hardness and low friction properties of tungsten carbide make it suitable for smaller, yet crucial weapon accessories such as knife blades, bayonets, gun sights, and hammers. These items benefit from the material's durability and resistance to abrasion.

Industrial Applications of Carbide Products

Beyond military uses, carbide products manufacturers also cater to a wide range of industrial applications:

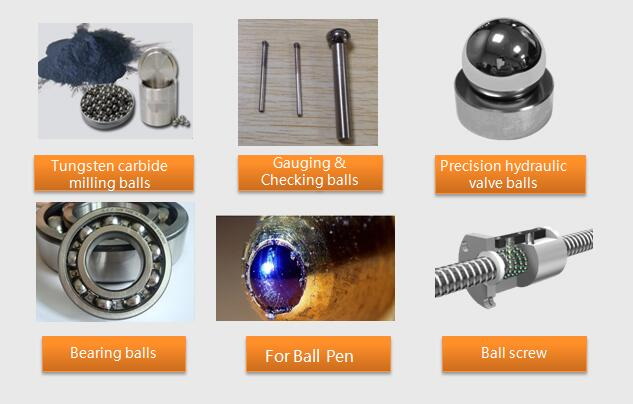

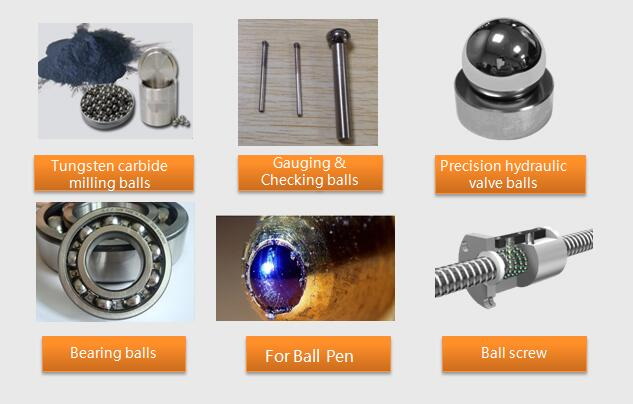

Pumps, Valves, and Compressors

In the manufacturing of pumps, valves, and fittings, parts made from tungsten carbide provide protection against premature wear in extreme environments. This is particularly important in industries dealing with abrasive media like quartz, sand, or salt.

Oil, Gas, and Petrochemical

Tungsten carbide is crucial in offshore technology, exploration, drilling, and power generation due to its ability to withstand erosion, abrasion, and corrosion. It significantly extends the lifespan of components in these harsh environments.

Chemical and Pharmaceutical

In large-batch production processes, such as technical tableting in pharmaceutical and chemical industries, tungsten carbide tools offer durable contours and improved lifespans. This is essential for maintaining efficiency and reducing downtime.

Sheet Metal and Metal Packaging

Manufacturers in the sheet metal processing industry benefit from tungsten carbide tools, which increase economic efficiency by minimizing wear and improving productivity.

Mining and Drilling

Tungsten carbide is widely used in mining and drilling applications, including roller-cutters, long wall shearer picks, and tunnel boring machines. Its wear resistance is critical in these demanding environments.

Construction and Building

In construction, tungsten carbide is used in tools for cutting and drilling concrete and stone. Its hardness ensures that these tools maintain their effectiveness even in the toughest conditions.

Automotive

The automotive industry also benefits from tungsten carbide, particularly in the production of wear-resistant components for engines and gearboxes. This enhances the durability and performance of vehicles.

Aerospace

In aerospace, tungsten carbide is used for components that require high strength and resistance to wear, such as rocket nozzles and engine components. Its ability to withstand extreme temperatures and pressures makes it ideal for these applications.

Advancements and Innovations

As technology advances, carbide products manufacturers are continually innovating to meet evolving demands. This includes developing new grades of tungsten carbide with improved properties, such as enhanced corrosion resistance or increased toughness. Additionally, advancements in manufacturing processes, like 3D printing, are opening new possibilities for complex carbide component designs.

Sustainability and Environmental Impact

The production of carbide products, particularly tungsten carbide, involves complex processes that can have environmental implications. Manufacturers are increasingly focusing on sustainable practices, such as recycling tungsten carbide scrap and reducing energy consumption during production. These efforts aim to minimize the environmental footprint while maintaining the high performance of carbide products.

Future Prospects

Looking ahead, the demand for carbide products is expected to rise due to their versatility and performance. As industries continue to evolve, the need for materials that can withstand extreme conditions will grow, driving further innovation in carbide manufacturing and application.

Conclusion

Carbide products manufacturers play a pivotal role in supplying both military and industrial sectors with high-performance materials. Tungsten carbide's unique properties make it an indispensable material for enhancing the effectiveness and reliability of equipment across various applications. As technology continues to evolve, the demand for carbide products is expected to grow, driving innovation and advancements in both military and industrial fields.

Frequently Asked Questions

1. What are the primary applications of tungsten carbide in the military?

Tungsten carbide is primarily used in the military for armor-piercing rounds, cutting tools, firearm components, ordnance parts, and weapon accessories due to its exceptional hardness and density.

2. How does tungsten carbide benefit industrial applications?

Tungsten carbide benefits industrial applications by providing wear-resistant components for pumps, valves, and compressors, extending the lifespan of equipment in harsh environments like oil and gas extraction, and improving efficiency in chemical and pharmaceutical processing.

3. What makes tungsten carbide suitable for cutting tools?

Tungsten carbide is ideal for cutting tools because of its high hardness and resistance to wear, allowing it to maintain its cutting edge even when machining tough materials like titanium and armor-grade steel.

4. How is tungsten carbide used in mining and drilling?

In mining and drilling, tungsten carbide is used in tools such as roller-cutters, long wall shearer picks, and tunnel boring machines due to its ability to withstand extreme wear and corrosion.

5. What are the advantages of using tungsten carbide in the chemical and pharmaceutical industries?

The use of tungsten carbide in these industries offers durable tool contours and significantly improved lifespans, reducing downtime and enhancing productivity in large-batch production processes.

Citations:

[1] https://www.carbide-products.com/blog/tungsten-carbide-for-weapon-industry/

[2] https://www.durit.com/industries

[3] https://www.samaterials.com/silicon-carbide-plates-for-advanced-armor-solutions.html

[4] https://ceramicmanufacturing.net/silicon-carbide-gallery/

[5] https://www.mmc-carbide.com/sea/technical_information/tec_guide/tec_guide_carbide

[6] https://www.defence-industries.com/articles/carbide-dies-and-military-applications

[7] https://tungstensuppliers.com/tungsten-carbide/

[8] https://www.innovationnewsnetwork.com/the-role-of-boron-carbide-ceramics-in-modern-defence-systems/42447/

[9] https://www.rtscut.com/military-defense.html

[10] https://www.alamy.com/stock-photo/carbide-end-mill.html

[11] https://www.istockphoto.com/photos/carbide

[12] https://www.hydrocarbide.com/our-markets/

[13] https://www.istockphoto.com/photos/carbide-tools

[14] https://www.cobracarbide.com/are-carbide-cutting-tools-the-future-of-manufacturing/

[15] https://www.fiven.com/markets-applications/defense-security/

[16] https://diamondabrasivesaustralia.com.au/index.php/tungsten-carbide-products/

[17] https://www.sciencedirect.com/science/article/pii/S2214914723000557

[18] https://www.k2esa.com.au/products/holemaking/solid-carbide-hss/

[19] https://www.kennametal.com/au/en/industries/defense.html

[20] https://generalcarbide.com

[21] https://www.linkedin.com/pulse/hard-truth-tungsten-carbide-military-applications-less-ethan-clarke-wrk4e

[22] https://www.timbecon.com.au/blogs/articles/freud-manufacturers-of-exceptional-carbide-tools

[23] https://www.samaterials.com/content/tungsten-in-military-use.html

[24] https://carbideprovider.com

[25] https://www.youtube.com/watch?v=dkFuZVBTTS0

[26] https://www.btccarbiderods.com/gallery.php

[27] https://www.alamy.com/stock-photo/tungsten-carbide.html

[28] https://www.shutterstock.com/search/production-carbide?image_type=photo&page=2

[29] https://www.kennametal.com/au/en/products/carbide-wear-parts/tungsten-solutions-for-defense-applications.html

[30] https://www.shutterstock.com/search/carbide-tools

[31] https://stock.adobe.com/search/images?k=carbide+cutting

[32] https://bulletproofplate.en.made-in-china.com/product/AwFGCpQHXOrY/China-Military-High-Quality-Bulletproof-Silicon-Carbide-Ceramic-Insert-Plate.html

[33] https://stock.adobe.com/search?k=carbide

[34] https://www.shutterstock.com/search/carbide-materials

[35] https://in.pinterest.com/pin/821203313277046036/

[36] https://www.istockphoto.com/photos/carbide-tools?page=2

[37] https://www.hydrocarbide.com/products/

[38] https://www.militaryaerospace.com/directory/electro-optics/optical-imaging/blog/55264240/avantier-inc-silicon-carbide-mirror-for-aerospace-applications