Content Menu

● Understanding Carbide and Tungsten Carbide

● Key Differences Between Carbide Bits and Tungsten Carbide Bits

● Advantages of Using Carbide Bits for Concrete

● When to Use Tungsten Carbide Bits

● Practical Applications

● Techniques for Concrete Drilling

● Choosing the Right Drill Bit

● Conclusion

● FAQs

>> 1. What is the main difference between carbide bits and tungsten carbide bits?

>> 2. Are carbide drill bits suitable for masonry?

>> 3. Can I use tungsten carbide bits on softer materials?

>> 4. How do I maintain my drill bits?

>> 5. Are there any safety precautions I should take when using these drill bits?

● Citations:

When it comes to drilling through tough materials like concrete, the choice of drill bits can significantly affect performance and efficiency. Among the options available, carbide bits and tungsten carbide bits are often discussed. This article will explore the differences between these two types of bits, their applications, advantages, and which one may be better suited for concrete drilling.

Understanding Carbide and Tungsten Carbide

Carbide Bits: Generally, when referring to carbide bits, we are talking about drill bits that have a tungsten carbide tip. These bits are made from a combination of tungsten and carbon, which makes them incredibly hard and durable. They are commonly used for drilling in various materials, including masonry, metal, and wood.

Tungsten Carbide Bits: Tungsten carbide is a specific type of carbide that is known for its extreme hardness. It is often used in industrial applications where durability and resistance to wear are critical. Tungsten carbide bits can be solid or tipped on a steel body.

Key Differences Between Carbide Bits and Tungsten Carbide Bits

| Feature | Carbide Bits | Tungsten Carbide Bits |

| Composition | Typically steel with a tungsten carbide tip | Solid tungsten carbide or tipped |

| Hardness | Very hard but less than solid tungsten carbide | Extremely hard (Mohs hardness 9-9.5) |

| Durability | Good durability | Exceptional durability |

| Brittleness | Less brittle than solid tungsten carbide | More brittle due to hardness |

| Applications | Versatile (wood, metal, masonry) | Best for heavy-duty industrial tasks |

| Cost | Generally more affordable | Higher cost due to material |

Advantages of Using Carbide Bits for Concrete

1. Durability: Carbide bits are designed to withstand high levels of wear and tear. They maintain their sharpness longer than traditional steel bits, making them ideal for repetitive tasks such as drilling into concrete.

2. Heat Resistance: The heat generated during drilling can dull a bit quickly. Carbide bits can handle higher temperatures without losing their cutting edge, allowing for more efficient drilling.

3. Versatility: While they excel in concrete applications, carbide bits can also be used on other materials such as wood and metal, making them a versatile choice for various projects.

4. Cost-Effectiveness: Although initially more expensive than standard steel bits, the longevity of carbide bits means they do not need to be replaced as frequently, leading to cost savings over time.

When to Use Tungsten Carbide Bits

1. Heavy-Duty Applications: If your project involves frequent drilling into extremely hard materials or reinforced concrete (with rebar), tungsten carbide bits may be the better option due to their superior hardness and durability.

2. Precision Work: For tasks requiring high precision in tough materials, tungsten carbide bits provide cleaner cuts and less chipping compared to other types of drill bits.

3. Industrial Use: In professional settings where tools are subjected to rigorous use, tungsten carbide bits are often preferred for their extended lifespan and reliability.

Practical Applications

- Concrete Drilling: Both types of bits can effectively drill into concrete; however, the choice between them may depend on the specific requirements of the job.

- Masonry Work: For masonry tasks involving brick or stone, carbide-tipped bits offer excellent performance without excessive wear.

- Metalworking: When drilling into metals like cast iron or stainless steel, both types of bits can be effective; however, tungsten carbide may outperform in terms of longevity.

Techniques for Concrete Drilling

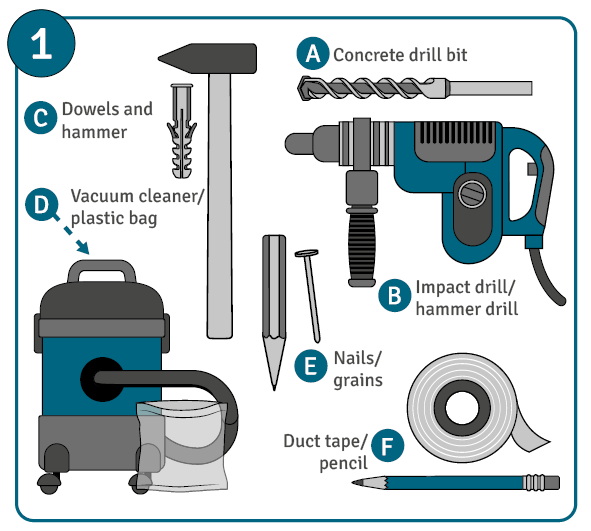

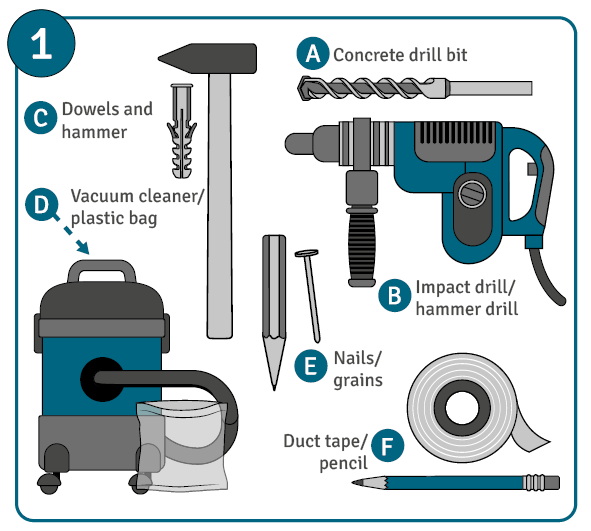

To achieve optimal results when drilling into concrete with either type of bit, it's essential to use proper techniques:

1. Start with a Pilot Hole: A smaller pilot hole helps guide the larger bit and prevents it from slipping off your mark.

2. Activate Hammer Mode: Use a hammer drill's special setting for concrete that combines spinning with hammering action to break through effectively.

3. Apply Steady Pressure: Begin at a slow speed to establish the hole; then gradually increase speed while applying steady pressure without forcing the drill.

4. Keep the Bit Cool: To prevent overheating, periodically pull the bit out to let it cool or sprinkle water into the hole.

5. Clear Dust Regularly: Remove accumulated dust from the hole as you drill to maintain visibility and efficiency.

Choosing the Right Drill Bit

Selecting the appropriate drill bit is crucial when working with concrete:

- Tip Type: Look for drill bits with high-quality carbide tips that can withstand abrasion and heat.

- Flute Design: A good flute design helps remove dust from the hole effectively while drilling.

- Compatibility with Drill Type: Ensure that your chosen bit is compatible with your hammer drill or rotary hammer for optimal performance.

Conclusion

In summary, whether carbide bits or tungsten carbide bits are better for concrete largely depends on the specific application and requirements of the task at hand.

- For general use in concrete drilling where cost-effectiveness and versatility are important, carbide bits are an excellent choice.

- However, if you require superior performance under heavy-duty conditions or precision work in extremely hard materials, then tungsten carbide bits would be the preferred option.

Ultimately, understanding the properties and applications of each type will help you make an informed decision that best suits your needs.

FAQs

1. What is the main difference between carbide bits and tungsten carbide bits?

Carbide bits typically have a tungsten carbide tip on a steel body while tungsten carbide bits can be solid or fully tipped with tungsten carbide material.

2. Are carbide drill bits suitable for masonry?

Yes, carbide drill bits are highly effective for masonry applications due to their hardness and durability.

3. Can I use tungsten carbide bits on softer materials?

While they can be used on softer materials like wood or plastic, they are primarily designed for tougher applications due to their brittleness.

4. How do I maintain my drill bits?

Regular cleaning after use and proper storage in a dry place can help maintain both carbide and tungsten carbide drill bits' longevity.

5. Are there any safety precautions I should take when using these drill bits?

Always wear appropriate safety gear such as goggles and gloves when using drill bits to protect against debris and sharp edges.

Citations:

[1] https://www.vicsawing.com.au/beginners-guide-to-concrete-drilling/

[2] https://www.bobvila.com/articles/best-drill-bits-for-concrete/

[3] https://kor-it.com/blogs/news/how-to-drill-into-concrete

[4] https://ruwag.co.za/blogs/news/everything-you-need-to-know-about-carbide-drill-bits

[5] https://iynxtools.de/en/blogs/how-to-s/ratgeber-stahlbeton-bohren-so-wird-s-gemacht

[6] https://www.boomandbucket.com/blog/best-concrete-drill-bit

[7] https://www.youtube.com/watch?v=Xq1tSFduzVo

[8] https://benchmarkabrasives.com/blogs/news/hss-vs-cobalt-vs-carbide-drill-bits-what-to-choose

[9] https://www.jungheinrich-profishop.co.uk/en/profi-guide/drilling-concrete/

[10] https://www.workshop.bunnings.com.au/t5/Best-Advice/What-are-your-tips-for-drilling-into-concrete/ta-p/138909

[11] https://toolstoday.com/learn/how-to-drill-into-concrete

[12] https://www.hilti.com.hk/c/CLS_POWER_TOOL_INSERT_7126/CLS_CONCRETE_MASONRY_DRILL_BITS_7126

[13] https://contentgrid.homedepot-static.com/hdus/en_US/DTCCOMNEW/Articles/how-to-drill-into-concrete-2023-step-8.jpg?sa=X&ved=2ahUKEwjHl5ymnfiKAxWQHEQIHU0RBgAQ_B16BAgDEAI

[14] https://www.bosch-professional.com/gb/en/innovation/the-best-concrete-drill-bits/

[15] https://www.youtube.com/watch?v=Lo7veFXq29A

[16] https://www.popularmechanics.com/home/g45642813/best-masonry-drill-bits/

[17] https://media.hswstatic.com/eyJidWNrZXQiOiJjb250ZW50Lmhzd3N0YXRpYy5jb20iLCJrZXkiOiJnaWZcL2RyaWxsLWJpdHMuanBnIiwiZWRpdHMiOnsicmVzaXplIjp7IndpZHRoIjoyODV9fX0=?sa=X&ved=2ahUKEwjC956mnfiKAxUfGtAFHZbQElsQ_B16BAgGEAI

[18] https://www.coweecarbide.com/tungsten-carbide-vs-carbide-drill-bits/

[19] https://www.tivoly.com/en/choose-hss-drill-carbide-drill

[20] https://www.youtube.com/watch?v=oC6BuUkWQ48