Content Menu

● Introduction to Tungsten and Tungsten Carbide

>> Tungsten

>> Tungsten Carbide

● Cost Comparison

>> Tungsten

>> Tungsten Carbide

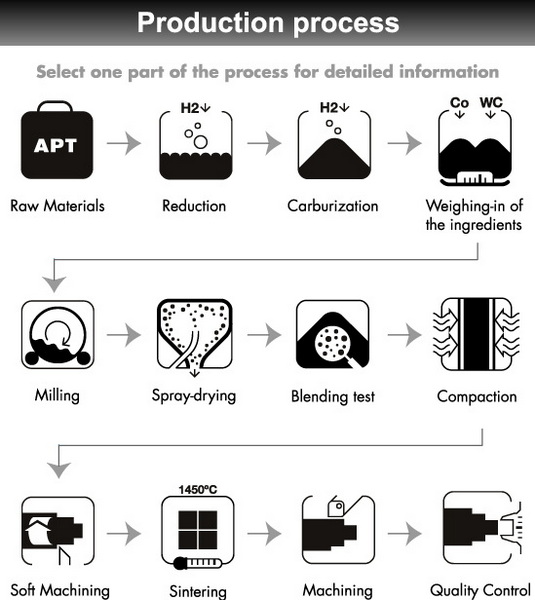

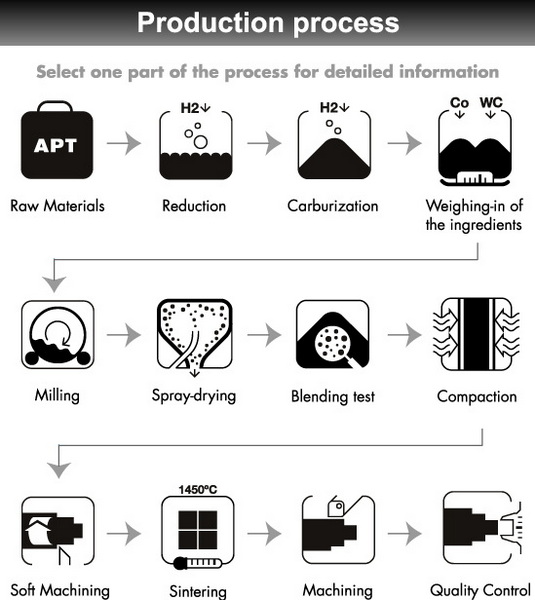

● Production Processes

>> Tungsten

>> Tungsten Carbide

● Applications

>> Tungsten

>> Tungsten Carbide

● Physical Properties

>> Tungsten

>> Tungsten Carbide

● Environmental and Health Considerations

>> Recycling and Sustainability

● Market Trends and Future Outlook

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary difference in hardness between tungsten and tungsten carbide?

>> 2. Why is tungsten carbide more expensive than tungsten?

>> 3. What are the typical applications of tungsten and tungsten carbide?

>> 4. How does the density of tungsten compare to tungsten carbide?

>> 5. Can tungsten carbide be resized or machined easily?

● Citations:

Tungsten and tungsten carbide are two materials that are often compared due to their distinct properties and applications. Tungsten is a naturally occurring metal known for its high melting point and density, while tungsten carbide is a compound made from tungsten and carbon, renowned for its exceptional hardness and wear resistance. In this article, we will delve into the differences between these materials, focusing on their cost, production processes, and applications.

Introduction to Tungsten and Tungsten Carbide

Tungsten

Tungsten is a rare metal with the atomic number 74 and is known for having the highest melting point among all metals at 3,422°C (6,192°F). It is used in various applications, including electrical contacts, heating elements, and alloying steel to increase its toughness. Tungsten's high density of 19.3 g/cm³ makes it ideal for use in counterweights and ballast materials.

Tungsten Carbide

Tungsten carbide, with the chemical formula WC, is a compound of tungsten and carbon. It is produced by heating tungsten powder with carbon at high temperatures, typically between 1,400°C and 1,600°C (2,550°F to 2,900°F). Tungsten carbide is significantly harder than tungsten, ranking between 9 and 9.5 on the Mohs hardness scale, making it ideal for cutting tools, mining equipment, and other wear-resistant parts.

Cost Comparison

Tungsten

Tungsten is generally less expensive than tungsten carbide due to its simpler processing requirements. The cost of refining tungsten to industrial purity is high, but the metal itself is less complex to produce compared to tungsten carbide. Additionally, tungsten can be sourced from various ores, which helps maintain a relatively stable supply chain.

Tungsten Carbide

Tungsten carbide is more expensive primarily because of its complex manufacturing process. It requires the combination of tungsten with carbon and often additional binders like cobalt or nickel, which adds to the cost. These binders help improve the material's toughness and facilitate its sintering into a cohesive form. However, the superior hardness and wear resistance of tungsten carbide justify its higher cost in demanding industrial applications.

Production Processes

Tungsten

Producing pure tungsten involves refining the metal from its ores, such as wolframite and scheelite. This process is intensive and costly due to the need for high purity levels. Tungsten is typically extracted through a series of chemical reactions and then purified using processes like hydrogen reduction.

Tungsten Carbide

Tungsten carbide production involves mixing tungsten powder with carbon and then sintering the mixture at high temperatures. This process is more energy-intensive and requires specialized equipment, contributing to its higher cost. The addition of binders like cobalt or nickel helps in achieving a uniform structure but also increases the complexity and expense of the process.

Applications

Tungsten

Tungsten is used in electrical components, heating elements, and as an alloying agent in steel. Its high melting point and density make it ideal for applications requiring thermal stability and substantial weight. For example, tungsten filaments are used in incandescent bulbs and halogen lamps due to their ability to withstand high temperatures.

Tungsten Carbide

Tungsten carbide is widely used in cutting tools, mining equipment, and wear-resistant parts due to its exceptional hardness and wear resistance. It is also used in jewelry for its scratch resistance and durability. In the aerospace industry, tungsten carbide is used for making components that require high strength and resistance to wear.

Physical Properties

Tungsten

- Density: 19.3 g/cm³

- Melting Point: 3,422°C (6,192°F)

- Hardness: 7.5 to 8 on the Mohs scale

Tungsten Carbide

- Density: Approximately 15.6 to 15.8 g/cm³

- Melting Point: About 2,870°C (5,198°F)

- Hardness: 9 to 9.5 on the Mohs scale

Environmental and Health Considerations

Both tungsten and tungsten carbide have environmental and health implications. Tungsten mining can lead to environmental degradation if not managed properly, while tungsten carbide's production involves the use of cobalt, which has raised health concerns due to its potential toxicity.

Recycling and Sustainability

Efforts are being made to recycle both tungsten and tungsten carbide to reduce waste and conserve resources. Recycling tungsten carbide is particularly challenging due to its hardness and the difficulty in breaking it down into reusable components. However, advancements in recycling technologies are helping to improve the sustainability of these materials. For instance, some companies are exploring methods to extract tungsten from scrap carbide tools, which can significantly reduce the environmental impact of new tungsten mining.

Market Trends and Future Outlook

The demand for both tungsten and tungsten carbide is expected to grow due to their critical roles in various industries. Tungsten carbide, in particular, will see increased demand in the aerospace and automotive sectors as manufacturers seek materials that can withstand high stresses and wear. Additionally, advancements in 3D printing technology may offer new opportunities for creating complex tungsten carbide components with reduced waste and improved efficiency.

Conclusion

In summary, tungsten carbide is generally more expensive than tungsten due to its complex production process and the addition of carbon and binders, which enhance its hardness and wear resistance. While tungsten is less expensive and suitable for applications requiring high thermal stability and density, tungsten carbide's superior properties make it indispensable in demanding industrial environments.

Frequently Asked Questions

1. What is the primary difference in hardness between tungsten and tungsten carbide?

Tungsten carbide is significantly harder than tungsten, with a Mohs hardness of 9 to 9.5 compared to tungsten's 7.5 to 8.

2. Why is tungsten carbide more expensive than tungsten?

Tungsten carbide is more expensive due to its complex manufacturing process, which involves combining tungsten with carbon and often additional binders, requiring specialized equipment and techniques.

3. What are the typical applications of tungsten and tungsten carbide?

Tungsten is used in electrical components and as an alloying agent in steel, while tungsten carbide is used in cutting tools, mining equipment, and wear-resistant parts.

4. How does the density of tungsten compare to tungsten carbide?

Tungsten has a higher density at 19.3 g/cm³ compared to tungsten carbide's 15.6 to 15.8 g/cm³.

5. Can tungsten carbide be resized or machined easily?

No, tungsten carbide is extremely hard and brittle, making it difficult to machine or resize without causing damage. It is typically machined in its "green" state before sintering.

Citations:

[1] https://blog.carbideprocessors.com/tungsten-carbide/price-difference-between-carbide-and-steel-wear-parts/

[2] https://en.wikipedia.org/wiki/Tungsten_carbide

[3] https://en.wikipedia.org/wiki/Tungsten

[4] https://cncpartsxtj.com/cnc-materials/difference-tungsten-and-tungsten-carbide/

[5] https://www.carpentryaccessories.com/auto-draft-2/

[6] https://www.vecteezy.com/free-photos/tungsten

[7] https://konecarbide.com/tungsten-vs-tungsten-carbide-differences-explained/

[8] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[9] https://cowseal.com/tungsten-vs-tungsten-carbide/

[10] https://www.stevengdesigns.com/blogs/news/the-difference-between-tungsten-and-tungsten-carbide

[11] https://www.menstungstenonline.com/Differences-between-Tungsten-and-Tungsten-Carbide-Rings.html

[12] https://www.reddit.com/r/ScrapMetal/comments/1f867b6/im_confused_about_tungsten_prices/

[13] https://www.thorstenrings.com/collections/tungsten-rings

[14] https://www.forevermetals.com/why-are-tungsten-carbide-rings-so-cheap/

[15] https://www.tungstenworld.com/collections/tungsten-rings-by-style

[16] https://stock.adobe.com/search?k=tungsten+carbide

[17] https://www.istockphoto.com/photos/tungsten-carbide

[18] https://www.istockphoto.com/photos/tungsten-metal

[19] https://www.aemmetal.com/news/tungsten-vs-tungsten-carbide-guide.html

[20] https://periodictable.com/Elements/074/pictures.html

[21] https://touchwood.biz/blogs/southafrica/what-is-the-difference-between-pure-tungsten-and-tungsten-carbide