Contentus menu

● Intellectus Tungsten Carbide

● Rudis materia praeparatio

● Mixing cum ligans

● Ecfingens

● Segregatio

● Consummatione processibus

● Imperium

● Applications Tungsten Carbide Tools

● Innovations in Tungsten Carbide Tool vestibulum

● Conclusio

● Faq

>> I. Quid facit Tungsten Tools Superior comparari aliis materiae?

>> II. Potest Tungsten Carbide Tools esse Recycled?

>> III. Quomodo autem peccat proprietatibus Tungsten carbide?

>> IV. Quid genera coatings applicantur ad Tungsten Carbide Tools?

>> V. Quid est Cobalt usus est in ligans in Tungsten carbide productio?

● Citations:

Tungsten Carbide Tools sunt nominati pro eximia duritia et diuturnitatem, faciens eos maluit choice in variis industriae applications, praecipue in cutting et machining. Hoc articulum déves in intricatus processus of vestibulum Tungsten Carbide Tools, exploring inter gradus a rudis materia praeparatio ad ultima uber.

Intellectus Tungsten Carbide

Tungsten carbide est compositum factum ex Tungsten et ipsum, formatam densa et dura materia. Est praesertim in productione cutting instrumenta ob suam facultatem ad sustinere altum temperaturis et resistere gerunt. Typicam duritiam Tungsten carbide ordines inter 8,5 ad IX in Mohs scale, faciens illud unum de durissima materiae praesto, secundo adamantino.

Quod unique proprietatibus Tungsten Carbide oriuntur ex suo microctructure et vinculum inter Tungsten et ipsum atomi. Hoc compositis non solum durum sed etiam habet optimum compressive viribus, faciens idoneam ad applications in quo resistentia ad deformationem est discrimine.

Rudis materia praeparatio

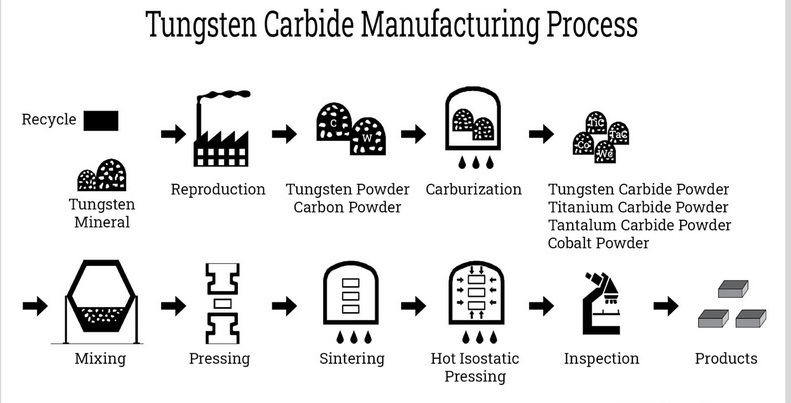

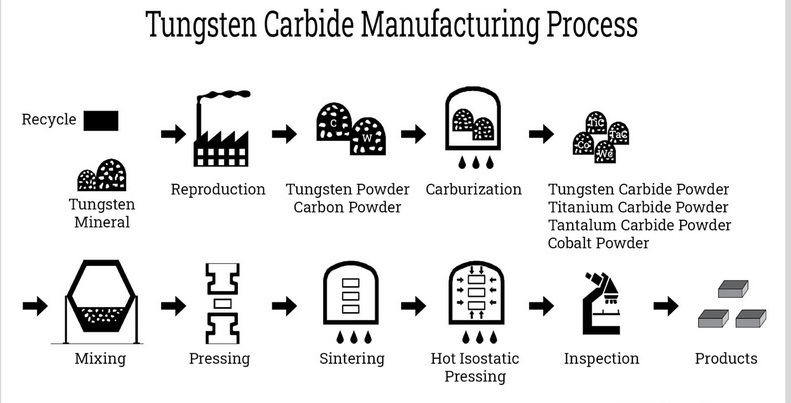

In vestibulum processus incipit cum praeparatione rudis materiae:

- Tungsten ore: et primaria fonte est Tungsten ore, quod oppressi et chemica tractata ad producendum Tungsten cadmiae.

- Carburization: in Tungsten cadmiae misceri cum ipsum (plerumque in forma graphite) et succensus ad altum temperaturis (per MCC ° C) in regulatae environment. Hoc processum converts Tungsten cadmiae in Tungsten carbide per eget reactionem removet oxygeni et combines ipsum cum Tungsten.

- pulveris productio: et inde Tungsten carbide est terra in denique pulveris, quae erit postea ad miscendas cum a ligans materia.

Hoc initial scaena est crucial ut puritas et qualis est rudis materiae directe afficit perficientur characteres ad ultima instrumenta. Immundia potest ad defectus ut compromissum tool integritate.

Mixing cum ligans

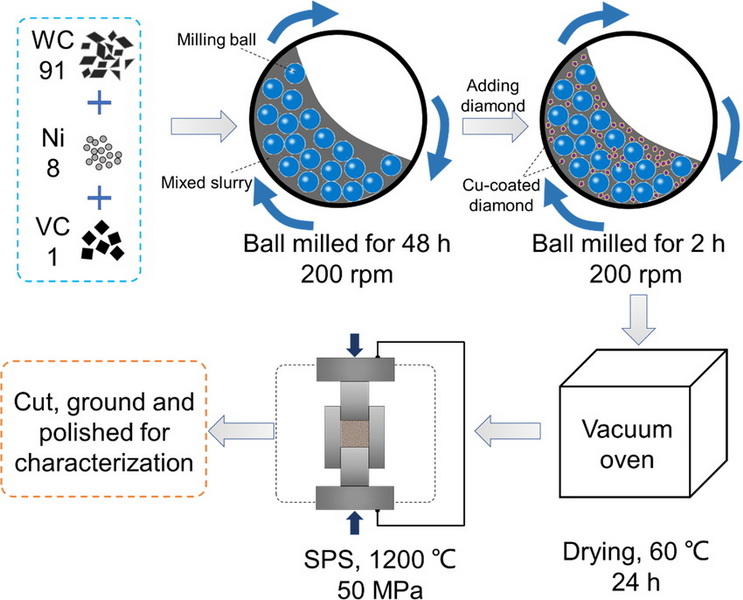

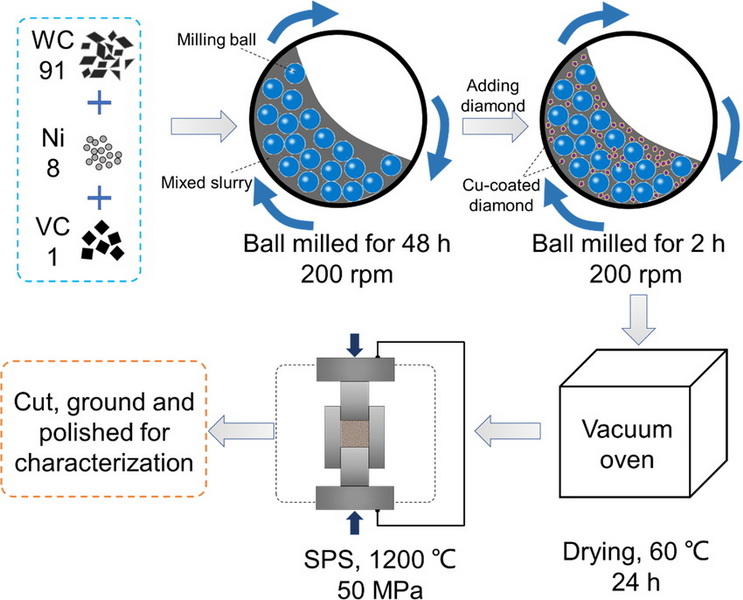

Post producendo Tungsten carbide pulveris, mixta est cum metallicis ligans, typice Cobalt et Nickel. Hoc gradum est crucial quod auget mechanica proprietatibus finalis uber:

- Mixing Processus: De Pulveres sunt combined in propria ratios per a pila molendini vel similis apparatu ut uniformis distribution. Hoc mixtisque est saepe mixtum cum solvents ad facilitate processing.

- Granulation, quod mixta pulveris potest subire granitia ad consequi desideravit particula magnitudinum, quod significantly impingit ad ultima tool scriptor perficientur.

Quod electio de ligans materia influxibus non solum ad lenta sed etiam ad scelerisque stabilitatem ad instrumenta. Cobalt est communiter favere debitum ad suum facultatem ad augendae lentium sine significantly comproming duritia.

Ecfingens

Semel in mixtionem processus est completum, deinde gradus involvit effingens pulveris in desideravit formas:

- urgeat: et granulatae mixtisque ponitur in formas et subiecta summus pressura (usque ad XX tons) ad creare 'viridi ' compactat similes cretam in constanty.

- Extrusionem: in quibusdam casibus, extrusionem modi sunt ad producendum virgas aut alia complexu figuris, ut requiratur ad propria applications.

Et effingens processus oportet diligenter dispensata ut uniformis density per connectatur materia. Variationes in densitate potest ad repugnantis in perficientur in machining operationes.

Segregatio

Siquidem unus de maxime discrimine gradus in vestibulum processus:

- calefactio: et pressed pacta sunt calefacta in a mortalis ad temperaturis vndique a MCD ° C ad MD ° C sub regi atmosphaeras (plerumque vacuum vel inertes Gas). Hoc calefactio concedit in ligans metallum (Cobalt et Nickel) ad conflandum et vinculum in Tungsten carbide particulas simul.

- DECREMENTUM: Per Requiem, in components shrink significantly (usque ad L%), ducens ad Densius ultima uber. Hoc reductionem oportet poni in pressione scaena ut finalis dimensiones occursum cubits.

Et sincering processus non solum enhances density sed etiam amplio mechanica proprietatibus ut duritiem et lenta. Propriis potestate super temperatus et atmosphaera per hoc scaena est essentialis ad consequi optimal results.

Consummatione processibus

Postquam in peccatum, additional peracta processibus potest adhiberi:

- molere: et Tools sunt Seges Saepe Terra Using Diamond Pectus rotae ad consequi precise dimensiones et superficiem finiatur. Hoc gradum ensures quod secans margines sunt acri et occursum restrictius tolerances requiritur ad effective machining.

- coating: Multi Tungsten Carbide Tools recipere superficiem coatings (ut Titanium nitride), quod augendae eorum gerunt resistentia et redigendum frictioni per operationem.

Consummatione processibus ludere a vitalis munus in determinandum quam bene a tool performs sub operational conditionibus. A bene-perfecta instrumentum potest significantly amplio cutting efficientiam et longum tool vitae.

Imperium

Qualis imperium est integralis per vestibulum processus:

- Testing: Exempla Ex singulis Batch sunt probata ad duritiam, gerunt resistentia, et alia mechanica proprietatibus ut obviam industria signa.

- Inspectionem: Final Products subeundi rigorous inspectionem ante packaging et shipping ad customers.

Quality imperium mensuras includit non-perniciosius testis modi ut ultrasonic temptationis, quae adjuvat identify interna vitiis absque damnosa productum. Consistent qualis certamen ensures reliability in perficientur per variis applications.

Applications Tungsten Carbide Tools

Tungsten Carbide Tools Reperio Applications per Various Industries Ob eorum diuturnitatem et perficientur characteres:

- Cutting Tools: usus extensive in machining operationes metalla, plastics et lignum.

- Mining Tools: usus in EXERCITATIO applications debitum ad facultatem ad resistere abrasive conditionibus.

- constructione Tools: Utietur ad cutting et effigies materiae in constructione projects.

- Oleum & Gas Industry: Used pro EXERCITATIO Equipment ubi extrema diuturnitatem requiritur debitum ad dura environmental conditionibus.

- Aerospace Applications: Essential ad vestibulum components quod requirere praecisione machining sub stregreent tolerances.

In versatility of Tungsten Carbide Tools facit eos necessaria trans multiple sectores, incessus demanda continua innovation in vestibulum processus.

Innovations in Tungsten Carbide Tool vestibulum

Sicut technology evolves, ita facit vestibulum processus in Tungsten Carbide Tools:

- Eminentive vestibulum: techniques ut 3D printing sunt explorati pro creando complexu geometries quod traditum modi non consequi effective.

- Advanced coatings: Research in novus coating materiae tendit ad ulterius enhancing gerunt resistentia dum redigo friction plus quam current solutions patitur.

- Dolor vestibulum Technologies: Integration IOT (Internet de rebus) cogitationes concedit manufacturers ad Monitor productio processibus in real-vicis, currit in altiorem et qualitas temperantis et peragitur in omni productione currit et qualitas imperium peragit.

Hae innovations non solum amplio efficientiam sed etiam aperta novum aditus ad applicationem ubi traditum Tooling modi potest cadere brevis.

Conclusio

In vestibulum processus Tungsten Carbide Tools involves plures gradus, singulis discrimine ad producendo summus qualitas products capax faciendo sub extremam conditionibus. Ex rudis materia praeparatio per effingens, mortificandi, consummatione et qualis imperium, omnis gradus confert significantly ad tool scriptor altiore perficientur et Vivacitas. Ut industries permanere evolve, ita quoque erit technologiae in producendo haec essentiales instrumenta. In ongoing progressiones in vestibulum artes et materiae scientia, possumus expecto etiam magis robust solutions tailored ad propria applications in variis sectores.

Faq

I. Quid facit Tungsten Tools Superior comparari aliis materiae?

Tungsten Carbide Tools sunt superior debitum ad extremam duritiam, gerunt resistentia, et facultatem ponere acumen sub alte accentus condiciones, faciens ea specimen ad sectionem dura metalla.

II. Potest Tungsten Carbide Tools esse Recycled?

Ita, Tungsten carbide potest esse recycled. Tollatur, ex tools potest reclaodie et reddi in novo vestibulum processus.

III. Quomodo autem peccat proprietatibus Tungsten carbide?

Sincering vincula in Tungsten carbide particulas simul sub calor et pressura, unde in densiore materia cum amplificata mechanica proprietatibus ut duritia et vires.

IV. Quid genera coatings applicantur ad Tungsten Carbide Tools?

Communis coatings includit Titanium nitride (stannum) et aluminium cadmiae (al2o3), quod augendae gerunt resistentia et redigendum friction in machining operationes.

V. Quid est Cobalt usus est in ligans in Tungsten carbide productio?

Cobalt militat quod efficax ligans quia aucta lenta dum permittens pro sufficienti bonding inter Tungsten carbide grana in mortificatione.

Citations:

[I] https://www.tool-tool.com/news/201202/Cutting-Tool-Manufacturing-Process/index.html

[II] https://www.zgccarbide.com/news/The-Manufacturing-Precess-of-Comented-Carbide-IsTs:-A-ComPisisting-Guide-39.html

[III] https://www.mmc-carbide.com/in/technical_information/tec_guide/tec_guide_carbide

[IV] https://www.alamy.com/stock-photo/tungsten-carbide.html

[V] https://eterterols.com/blogs/tutorials/tungsten-carbide-an-informive-guide

[VI] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[VII] https://www.7leaders.com/blog/tungsten-carbide

[VIII] https://huanatools.com/how-to-make-tungsten-carbide-rods/

[IX] https://www.tungstenman.com/tungsten-carbide-tools-the-pros-and-cons.html

[X] https://todaysmachinedworld.com/magazine/how-it-works-making-tungsten-carbide-cutting-tools/

[XI] https://tuncomfg.com/bout/faq/

[XII] https://www.axismateria.co.jp/aml_en/technical/manufacturing-process-material-characteristic.html

[XIII] https://www.youtube.com/watch?v=95ys7W66-BI

[XIV] https://www.mcc-carbide.com/in/technical_information/tec_guide/tec_guide_carbide

[XV] https://www.Evyrty-cemented-carbide.com/en/procascens/

[XVI] https://Repository.Ap.Za/Bitstream/Handle/2263/24896/03Chapter3/24896/03Chapter3.pdf?sequence=4

[XVII] https://www.youtube.com/watch?v=0QRynzj_lz4

[XVIII] https://www.psmdustries.com/yillik/tungsten-carbide-manufacturing-process

[XIX] https://todaysmachiningworld.com/magazine/how-it-works-making-tungsten-carbide-cutting-tools/

[XX] https://www.7leaders.com/blog/tungsten-carbide

[XXI] https://www.istiGockphoto.com/de/bot-wall?Retururn%2FDE%2FPhotos%2FTungSten-carbide

[XXII] https://www.mmc.co.jp/corporate/en/news/2024/news20240529.html

[XXIII] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide

[XXIV] https://tock.adobe.com/search/images?k=carbideEcutting

[XXV] https://www.hit-tw.com/newsdetails.aspx?nid=298

[XXVI] https://www.carburr.net/faq/

[XXVII] https://huanatools.com/6-facts-bout-tungsten-carbide-burrs-and-how-to-e-them/

[XXVIII] https://www.linkedin.com/pulse/3-questions-tungsten-carbide-buttons-shijin-lei

[XXIX] https://www.mtb2b.tw/en/Articles/182