Contentus en nos explorarent proprietatibus nigrum

● I. De scientia post Tungsten Carbide Properties

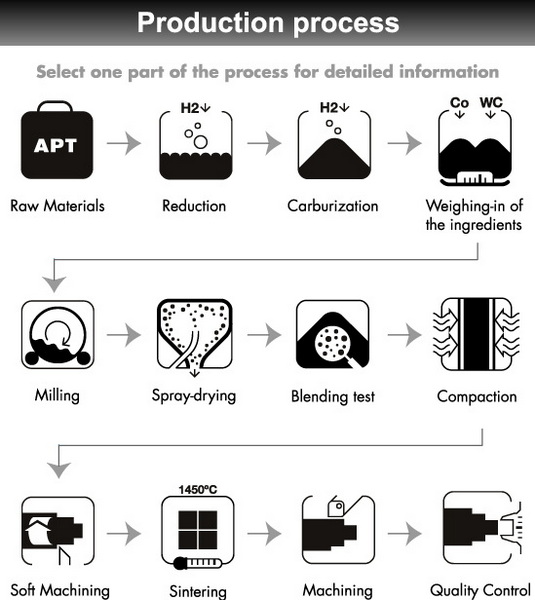

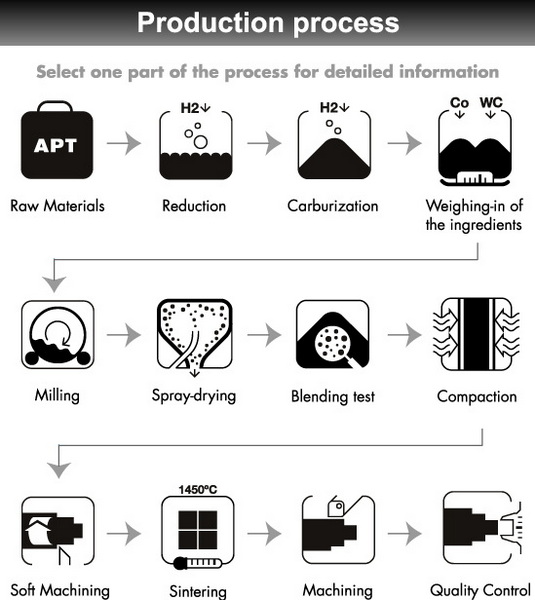

● II. Tungsten Carbide Productio Processus: A gradum-per-gradus analysis

>> 2.1 rudis materia praeparatio

>> 2,2 carburization: creando WC Phase

>> 2.3 milling et ligans additionem

>> 2,4 formatam et peccare

>> 2.5 Post-processus

● III. Industrial Applications Dictate processus parametri

● IV. Qualitas imperium: et facere, aut-confractus factor

● V. productio technologies emergentes

● Conclusio

● FAQs: Tungsten Carbide Production

>> I. Quid est Cobalt in malle ligans in WC productio?

>> II. Quomodo ergo sincosing atmosphaera productum species?

>> III. Quid causae 'Cobalt Pololing ' in sintering?

>> IV. Potest recycled WC esse in productione?

>> V. Quomodo additive vestibulum modos mutare WC Applications?

● Citations:

Tungsten carbide (WC) stat sicut angularis ex modern industria, enabling progressiones in vestibulum, industria, aerospace et defensionem. Eius eximia duritia, gerunt resistentia, et scelerisque stabilitatem facere eam necessarium pro altus-accentus applications. Sed haec proprietatibus non inhaerens rudis materiae, ut emerge a meticum dispensata productionem processus. Hic articulus examines quam quisque scaena Tungsten carbide vestibulum directe impingit industriae perficientur, sustinetur per technica insights et processus diagrams.

I. De scientia post Tungsten Carbide Properties

Tungsten carbide trahit ejus unmatched mechanica characteres ex suis nuclei structuram: Tungsten Atoms Bonded cum Carbon in rigidum cancer, saepe combined cum Cobalt ligula. Hoc compositum Achieves:

- Durness (2,200-2,400 HV30) excedens plus Steels

- Liquid Point 2,870 ° C, ideal ad summus temperatus environments

- compressive fortitudinem usque ad 6,000 MPa, discrimine ad sectionem Tools

- Tungsten Carbide atomic structuram Diagram

- nuclei Ordinatio WC, CO

Frumentum terminus Engineering: Recent Studies ostendere quod addit 0,5% Chromium carbide (CR3C2) inhibits frumentum incrementum in morte, maintaining submemicron structuras quod boost duritiam per XII% (Journal of Materials, MMXXIV).

II. Tungsten Carbide Productio Processus: A gradum-per-gradus analysis

2.1 rudis materia praeparatio

Processus incipit cum Tungsten ore (Schelelite vel Wolframite) et summus puritas carbon fontibus:

Tungsten extraction:

- Ore est primum concentrari via gravitas separationem (XCV% wo3 recuperatio)

- alkaline leaching converts scheelite (cawo4) ad sodium Tungstate (Na2wo4)

- apta crystallization: solution PH continetur ad 2.5-3.0 ad praecipiti Ammonium paratungstate

- Reduction: Apostolis, Apostolica est in hydrogenia Furnorum at 600-1,000 ° C creare Tungsten metallum pulveris.

- Particle Size Distribution: 2-15 μm effectum via hydrogenii fluxus rate imperium

- Carbon Praeterea: Tungsten Pulvis est mixta cum Carbon Nigrum in XCIV: VI WC, C Ratio (typical).

Industrial ictum:

- Mining Industry Case: A 0,3% oxygeni contagione in W pulveris reduci terebro frenum vitae per XLI% (Sandvik Mining Report, MMXXIII).

- Military Signa (Mil-T-(CCXIV) C.) Mandate <0.05% sulphuris contentus ad armis, penetrabilibus cororum.

2,2 carburization: creando WC Phase

In W + c m angelis subit carburization in vacuo Furnorum ad 1,400-2000 ° C:

W + c → WC (ΔH = -40.5 KJ / Mol)

Processus innovations:

- Multi-Zonam Furnaces ponere ± V ° C uniformitas (vs. Traditional ± XV ° F)

- Real-Time CO Cras Detects imperfecta reactiones

Analysis tempus:

- Undercarburization Folia fragile W2C Augmenta

- Overcarburization creates Free Carbon (Graphite) flakes

- Carburization fornacem schematic

- Industrial-scale carburization setup

Energy Efficens: Modern Rotarius Furnorum Redigere Energy consummatio per XXX% per Regeneralis calefacit (Carbide Processors Inc., MMXXIV).

2.3 milling et ligans additionem

WC pulveris est pila-millque cum Cobalt (5-25% pondus):

Advanced milling:

- Turbula mixers consequi 99,9% Homogeneity in VIII horis vs. XXIV horas pro conventional modi

- ethanol et Hexane impedit oxidatio in wet milling

Seneca Alternatives:

- Nickel: in mordendo environments (eget valvulae)

- Ferrum-Chrome: nam summus temperatus applications (Steel volubilem Mills)

- Case Study: KenNametal scriptor KCS30B Grade usus VI% CO 0,8 μm in PCB Micro-terebras Achieving 50,000+ foramina per instrumentum.

2,4 formatam et peccare

Pressed 'viridi ' partes sunt peccata in vacuo / Hydrogenia Furnorum ad 1,350-1,500 ° C

Modi formatam:

- Frigus Isostatic urgeat (CIP): 200-400 MPA pressura ad universa geometries

- Iniectio CUMATIUM: nam <I mm Wall Crassitudo components (dentalis burs)

PROGRESSUS

- Hot Isostatic urgeat (coxae): 1,400 ° C + C MPa Argon Excludit RELICTUM Porosity

- Proin Deficiens cutsing exolvuntur Tempus per LX% (Fraunhofer Institutum, MMXXV)

2.5 Post-processus

Discrimine consummatione vestigia includit:

Dinding:

- Electrolytic in-processus coluisse (Elid) molere Achieves Achieves μm 0.01 μm

- V, axis cnc moles figura turbine ferrum sigillis in II μm tolerantia

Coatings:

- Altin: nam arida machining usque ad 1,100 ° C

- Diamond Pectus, sicut Carbon (DLC), reduces frictionis in afferentem applications

- Laser Templatur, Superficies exemplar incremento lubricant retention per LXX% in oleum EXERCITATIO Tools (Baker Hughes Patentes US2024356701A1).

III. Industrial Applications Dictate processus parametri

- industria key wc proprietatibus processu adjustments

- metallum secare in ore aciem, æstus resistentia ultra-denique grana (0.2-0.5 μm), humilis co

- Mining impulsum resistentia crassum grana (5-10 μm), 10-15% co

- Aerospace lassitudine resistentia coxae peccare (1,400 ° C / C MPA)

- Semiconductor praecisione Isostatic urgeat <0.1 μm superficiem metam

- Medical Biocompatibility Nickel-Free Bodcient, Speculum Polishing

Eminentive Vestibulum Exemplum: GE Aviation scriptor 3D-typis WC Turbine Signstand 1,200 ° C exhauriunt gases, reducendo fuel adolebitque per 2.7%.

IV. Qualitas imperium: et facere, aut-confractus factor

Advanced Testing ensures productionem constanty:

Analysis eget:

- libs (laser-adductus naufragii spectroscopy) detects PPM-campester impurities

- Xrf Mapping Verifies Co distribution Homogeneity

Mechanica testis:

- Transversus RUMPTURA Fortitudo (TRS): 3,500-4,500 MPA pro Cutting Gradus

- Weibull Modulus> XV indicat princeps reliability

Digital Fetus: Siemens 'Processus simulator praedicit PRAETENDATIO DECREMENTUM in 0,3% accuracy usura AI MODELLS eruditus in 50,000+ batches.

V. productio technologies emergentes

Eminentive vestibulum:

- Binding Jetting Dat conformis refrigerationem channels in stamping moritur

- Diriged Energy Deposition (Ded) Repairs WC components cum XCV% density

Nanocrystalline WC:

- Clark Plasma Plasma (SPS) producit L NM grana

- Graphene, Reinforced WC (0.1 WT%) crescit fractura lenta per XL%

Sustainable productio:

- Zinc-redivling recuperat XCVIII% WC ex Scrap

- Plasma, assisted carburization secat CO2 emissiones per LV%

Conclusio

Et Tungsten Carbide Productio Processus non modo a vestibulum sequentia-suus 'a praecisione ipsum feat quod decernit Global Industrial facultatem. De carburization fornacem scriptor temperatus curvas ad Cobalt ligans scriptor nanometer-scale distribution, singulis modularis directe confligant component perficientur in missione, discrimine applications. Ut industrias demanda altior efficientiam et diuturnitatem, progressiones in WC vestibulum permanere unlocking novus fines in materiae scientia.

FAQs: Tungsten Carbide Production

I. Quid est Cobalt in malle ligans in WC productio?

Cobalt optimally statera widytability, ductility et corrosio resistentia. Nickel et ferrum alternatives reducere instrumentum vitae per 30-50%.

II. Quomodo ergo sincosing atmosphaera productum species?

Hydrogenii atmosphaerae ne oxidation sed requirere strictae ros-punctum imperium (-50 ° C). Argon adhibetur ad altus-co Alloys ad vitare hydrogenii embrisslement.

III. Quid causae 'Cobalt Pololing ' in sintering?

Pulvis peenen Powder aut celeri calefactio (> X ° C / min) ducit ad localized coacta, reducing duritiam a 15-20%.

IV. Potest recycled WC esse in productione?

Ita, usque ad XXX% REDIVIVUS pulveris proprietatibus. Zinc processum reclaims WC ex exiguo cum XCIX% puritatem.

V. Quomodo additive vestibulum modos mutare WC Applications?

3D-typis WC dat complexu Geometries sicut cancellos structurae ad lightweight armis, impossibile est traditional urgeat.

Citations:

[I] https://www.linde-amt.com/resource-library/Articles/tungsten-carbide-power

[II] https://www.youtube.com/watch?v=ZJKVI0CMTX0

[III] https://www.kovametalli-in.com/manufacturing.html

[IV] https://www.alamy.com/stock-photo/tungsten-carbide.html

[V] https://www.mmc-carbide.com/sea/technical_information/tec_guide/tec_guide_carbide

[VI] https://www.carbide-part.com/blog/comPisisting-Of-TungSten-The-advents-of-tungsten-carbide-aplics/

[VII] https://www.carbide-products.com/blog/tungsten-carbide-production-procascepess/

[VIII] https://ceramics.org/ceramic-tech-today/tungnment-made-academia-government-industry-academia-invete-Additively-Manufacturing-Cemed-carbide-parts/

[IX] https://www.linkedin.com/pulse/tungstenCarbide-Production-Precess-Tungsten-Carbide-shijin-lei

[X] https://www.samaterials.com/content/application-of-tungsten-in-modern-industry.html

[XI] https://www.linde-amt.com/resource-library/Articles/tungsten-carbide

[XII] https://www.istiCarbhoto.com/photos/tungsten-carbide

[XIII] https://www.youtube.com/watch?v=L7NXS4AJRWS

[XIV] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide?page=3

[XV] https://www.simon.group/fileadmin/user_8.22.4Web.pdf

[XVI] https://www.ascantungsten.com/blogs/news/why-tungsten-is-the-preferred-material-for-critical-canadian-industries

[XVII] https://www.rodler.com/investing-in-tungsten-production-opportunities-and-challenges/

[XVIII] https://www.millercarbide.com/all-about-tungsten-carbide-burrs-moragturing-aplication-and-moring-

[XIX] https://Repository.up.Ac.za/bitstream/handle/2263/24896/03Chapter3/24896/03Chapter3.pdf?sequence=4

[XX] https://patents.google.com/patent/us4008090a/en

Handle / MMCCLXIII / (XXIV) DCCCXCVI / 03Chapter3.pdf? Sequence = IV

[XX] https://patents.google.com/patent/us4008090a/en