Contentus menu

● Definiens duritia in materiae scientia

● Tungsten Carbide Durness Metrics

>> I. Mohs duritia

>> II. Vickers Duritia

>> III. Rockwell Duritia

● Factors Influencing Tungsten Carbide Durness

>> I. Frumentum magnitudine

>> II. Cobalt BENTGE QUODEMIS

>> III. Vestibulum processus

● In scientia post Tungsten carbide scriptor duritia

>> I. Crystalli structuram

>> II. Covalens Bonding

>> III. Metallicis mores

>> IV. Mycobacterium configuratione

● Applications leveraging Tungsten Carbide Durness

>> I. Cutting Tools

>> II. Gere-repugnans components

>> III. Jewelry

>> IV. AEROSPACE et defensionis

>> V. Medical instrumenta

● Tungsten Carbide vs. Dura Materials

>> I. Diamond Pectus

>> II. Silicon Carbide (SIC)

>> III. Titanium

>> IV. Cubic Boron Nitride (CBN)

>> V. Alumina (Al2o3)

● Challenges et limitations of Tungsten carbide

>> I. INDIGNITAS

>> II. Cost

>> III. Processing difficultatibus

>> IV. Environmental de

● Future Developments in Tungsten Carbide Technology

>> I. Nanostructured WC

>> II. Composita materiae

>> III. Advanced coatings

>> IV. Vestibulum additive

● Conclusio

● FAQs

>> I. Quid est Mohs duritiam Tungsten carbide?

>> II. Quid est Tungsten carbide duritia metiri?

>> III. Potest Tungsten Carbide Scratch Diamond?

>> IV. Quid facit Cobalt contentus afficit duritia?

>> V. Est Tungsten Carbide in Consumer products?

● Citations:

Tungsten Carbide (WC) est unus de durissima machinatum materiae in existentia, nobilis pro eius eximia diuturnitatem et resistentia ad induendum. Hoc compositis, formatae per Bonding Tungsten et ipsum atomos, habet reviseded industria vndique a vestibulum ornatu. Et duritia est secundo adamantino, faciens illud necessarium est summus accentus applications. Hoc articulum explorat duritiam Tungsten carbide , mensurae modi, influens factores, applications, et comparationes cum aliis materiae.

Definiens duritia in materiae scientia

Durness refers to a materia resistentia ad permanens deformatio, scalpendi, aut incisum. Nam Tungsten carbide, quod proprietas est discrimine quod determinat perficientur in abrasive environments. Commune stateram in mensuræ duritiam includit:

- Mohs scale: a qualita ordinal scale (1-10) comparet Mineralis resistentia ad scalpendi.

- Vickers Duritia (HV), mensuras superiores incisum resistentia usura adamantem pyramidis.

- Rockwell duritia (HRA, HRC) Quantifies penetratio sub specifica onerat.

Tungsten Carbide Durness Metrics

I. Mohs duritia

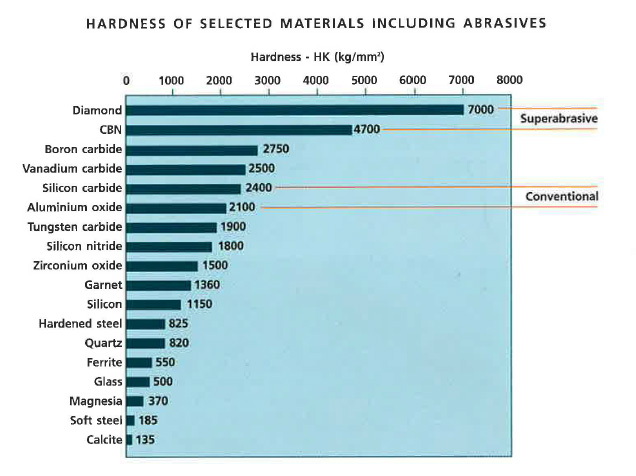

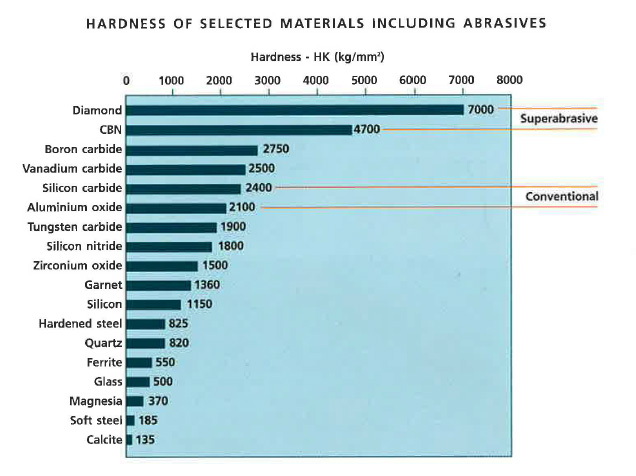

Tungsten Carbide Ordinum 9-9.5 in Mohs scale, sicut infra Diamond (X). Hoc facit magis quam maxime steels (4-8.5) et Ceramics sicut alumina (IX).

II. Vickers Duritia

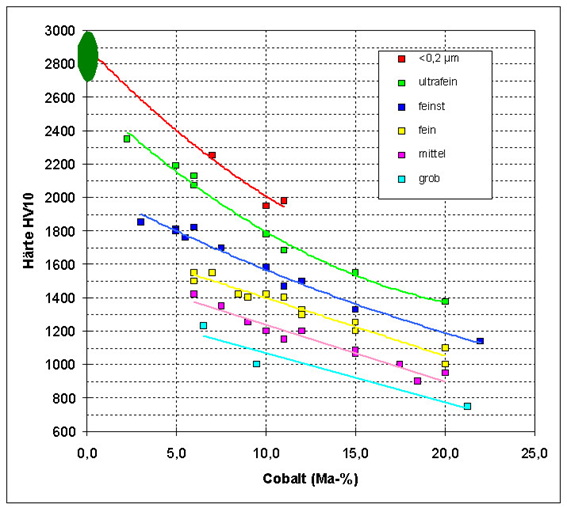

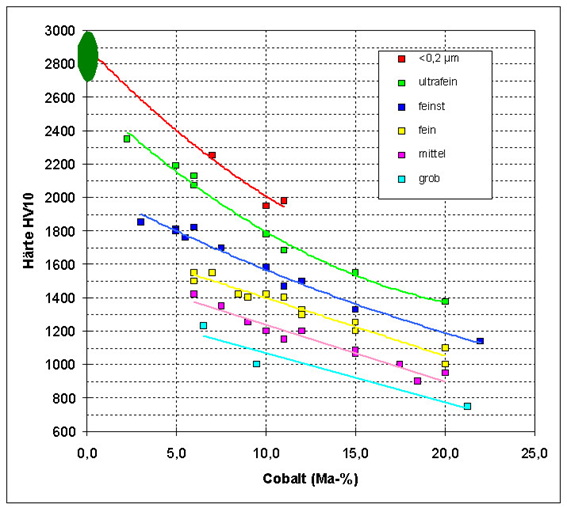

Using a Diamond Pectus, Tungsten Carbide scores 1,500-2,600 HV, fretus grano magnitudine et Cobalt contentus. Denique-grades cum humilis Cobalt ligans (3-6%) consequi summum duritiam.

III. Rockwell Duritia

Tungsten carbide typically mensuras 88-94 hra in rockwell scale, comparabilem ad grave instrumentum Steels sed superior gerunt resistentia.

Factors Influencing Tungsten Carbide Durness

I. Frumentum magnitudine

- denique (0.2-0.8 μm): superiore duritia ex reducitur intergranular spacing.

- crassum grana (> I μm): melior lenta sed inferior duritia, idealis ad impulsum-grave applications sicut metalla terebras.

II. Cobalt BENTGE QUODEMIS

- humilis Cobalt (3-6%): maximizes duritiam autem crescit fragtileness.

- High Cobalt (10-20%): Enhances lenta ad sumptu ex duritia.

III. Vestibulum processus

- Sincerus temperature: altius temperaturis (1,400-1,600 ° C) optimize densitas et duritiem.

- Post-Deining Treatments: coatings sicut Titanium nitride (stannum) porro amplio superficiem duritia.

In scientia post Tungsten carbide scriptor duritia

Intelligendo eximia duritia Tungsten carbide requirit in suum nuclei structuram et vinculum machinationes. In materia est unique proprietatibus a compositum ex factors:

I. Crystalli structuram

Tungsten carbide forms a Hexagonal prope-facis (HCP) Crystal structuram. Hoc dispositionem permittit ad efficient stipare in atomorum, conlatis ad altum densitatem et duritiem.

II. Covalens Bonding

Et fortis covalent vincula inter Tungsten et ipsum atomos creare rigidum cancellos, quod resistit deformatio. Hi vincula sunt directional et localized, providente eximia vires.

III. Metallicis mores

Dum praesertim covalent, Tungsten carbide et exhibet quaedam metallicis vinculum characteres. Hoc combination enhances sua lenta comparari ad pure covalent materiae sicut adamas.

IV. Mycobacterium configuratione

In electronic configuratione Tungsten (5d ^ IV 6s ^ II) concedit fortis hybrosization cum Carbon scriptor electrons, formatam firmum et rigidum vincula quae conferre ad materiam duritiam.

Applications leveraging Tungsten Carbide Durness

I. Cutting Tools

- finis molestus, terebro bits, et adiicit ponere acri marginibus etiam ad altum temperaturis, reducendo tool gerunt.

- Comparisons:

| Materia |

durities (HV) |

Gerunt resistentia |

| HSS |

800-900 |

Humilis |

| Ceramics |

1,200-1,800 |

Moderor |

| WC |

1,500-2,600 |

Extremo |

II. Gere-repugnans components

- Mining Equipment (tips Tips, Crusher Lamella) Outststo abrasive petram contactus.

- Industrial nozzles et valvulae ferre erosive fluidorum.

III. Jewelry

- Nuptialis vincula retinere Poloniae infinitum ex scalpere resistentia.

IV. AEROSPACE et defensionis

Tungsten carbide scriptor duritia facit eam invaluable in aerospace et defensionem applications:

- Armor, penetrabilior rounds: WC coros augendae penetrationem dat.

- Turbine Blade coatings: amplio exesa resistentia in jet engines.

- Spacecraft components: sustinere micrometeorite impacts et spatium obstantia.

V. Medical instrumenta

Et Biocompatibility et durities Tungsten carbide facere idoneam ad variis medical applications:

- Chirurgicam instrumenta: Scalpello et acus acus tips ponere aculeos.

- dentalis terebras: praecisione secans of dens electre et dentin.

- orthopaedicarum implantatorum: gere, repugnans iuncturam supplementum.

Tungsten Carbide vs. Dura Materials

I. Diamond Pectus

- Diamond Pectus (X Mohs) Vs. WC (9-9.5 Mohs).

- Usus Case: Diamond Pectus pro Ultra-praecisione secans; WC ad sumptus-effective diuturnitatem.

II. Silicon Carbide (SIC)

- Durness: Sic (9,5 Mohs) Vs. WC (9-9.5 Mohs).

- Thermal Stabilitatem: SIC excellit in summus temperatus environments.

III. Titanium

- Durness Titanium (VI Mohs) Vs. WC (IX Mohs).

- Diuturnitatem: WC outperforms Titanium in gerunt resistentia.

IV. Cubic Boron Nitride (CBN)

- Durness: CBN (9.5 Mohs) WC (9-9.5 Mohs).

- Application: CBN maluit pro machining durior, cum suis eget stabilitatem.

V. Alumina (Al2o3)

- Durness: Alumina (IX Mohs) Vs. WC (9-9.5 Mohs).

- Sumptus: Alumina est magis frugi sed minus lenta quam WC.

Challenges et limitations of Tungsten carbide

Quamvis eius eximium duritiam, Tungsten carbide facies aliqua challenges:

I. INDIGNITAS

Excelsa duritia saepe correlates cum augeri fragtilitatem. WC potest chip vel fractura sub subito impingit, praesertim in humilis-Cobalt grades.

II. Cost

Tungsten est relative rara metallum, faciens WC magis pretiosa quam multis alternative materiae.

III. Processing difficultatibus

In princeps duritiam WC facit effingit et machining in ultima uber provocans, saepe requiring specialized techniques quasi electrica missionem machining (EDM).

IV. Environmental de

Tungsten Mining et Processing potest habere environmental impacts et redivivus WC products est essentiale ad sustineri.

Future Developments in Tungsten Carbide Technology

Research continues ad augendae proprietatibus et Applications of Tungsten Carbide:

I. Nanostructured WC

Developing Nanocrystalline Tungsten carbide poterat ultra emendare duritia dum maintaining lenta.

II. Composita materiae

Combining WC cum aliis durum materiae sicut adamas vel CBN potest creare synergistic melioramentis in perficientur.

III. Advanced coatings

Multi-iacuit coatings et nove depositione techniques aim ad augendae superficiem proprietatibus WC instrumenta et components.

IV. Vestibulum additive

3D printing of Tungsten carbide partes non patitur ad universa geometries et customized materiam proprietatibus.

Conclusio

Tungsten carbide scriptor unice delectatur duritia caulibus ex eius densa hexagonal crystal structuram et optimized vestibulum processus. Cum Mohs Rating de 9-9.5 et Vickers Durness usque ad 2,600 HV, quod outperforms Most metallis et LATERAMEN in abrasive applications. Balancing duritia cum lenta per frumenti magnitudine et ligans referendo permittit tailored solutions ad industries quasi aerospace, metalla et jewelry. Sicut technology progreditur, Tungsten carbide manet in angularem de summus perficientur ipsum, cum ongoing research promittens etiam maior capabilities in futurum.

FAQs

I. Quid est Mohs duritiam Tungsten carbide?

Tungsten Carbide Ordinum 9-9.5 in Mohs scale, faciens magis quam ferro leviter mollior quam adamas.

II. Quid est Tungsten carbide duritia metiri?

Communi modi includit Vickers (HV), Rockwell (Hra), et Knoop probat, quod uti adamas inditters ad assess resistentia.

III. Potest Tungsten Carbide Scratch Diamond?

No. Diamond Pectus (X Mohs) est durius et can scalps Tungsten carbide, sed WC est saepe solebat interficiam vel Polonica crystallini debitum ad suam affordability.

IV. Quid facit Cobalt contentus afficit duritia?

Superiore Cobalt reduces duritiam creando mollior ligans matrix inter WC grana. Humilis-Cobalt grades (3-6%) prioritize duritia.

V. Est Tungsten Carbide in Consumer products?

Ita. Commune Applications includit jewelry, felis vibrationis motores et summus finem vigilia components.

Citations:

[I] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[II] https://en.wikipedia.org/wiki/tungsten_carbide

[III] https://konecarbide.com/tungsten-vs-tungsten-carbide-diffferferences-explained/

[IV] https://create.vista.com/photos/tungsten-carbide/

[V] https://eterterols.com/blogs/tutorials/tungsten-carbide-an-informive-guide

[VI] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[VII] http://www.carbidechnologies.com/faqs/

[VIII] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[IX] https://www.retopz.com/57-freqrequently-asked-questions-faqs-about-tungsten-carbide/

[X] https://www.azom.com/article.aspx?articleid=2278

[XI] https://www.demetalloys.co.uk/what-is-tungsten-carbide

[XII] https://www.basiccarbide.com/tungsten-carbide-grade-chart/

[XIII] https://www.britannica.com/science/tungsten-carbide

[XIV] https://www.bladorums.com/threads/carbide-hardness-chart.1705186/

[XV] https://www.matweb.com/search/datasheet.aspx?matguidguid=e68b647b86104478A32012CBD5Ad3ea&ckck=1=1

[XVI] https://www.azom.com/properties.aspx?articleid=1203

[XVII] https://www.imetra.com/tungsten-carbide-material-properties/

[XVIII] https://www.shutterstock.com/search/%22tungsten-carbide%22?page=3

[XIX] https://tts://stock.adobe.com/search?k=tungsten+carbide

[XX] https://www.istiCKPHOTO.com/DE/Bot-Wall?RSURNL=%2FDE%2FPHOTOS%2FTungSten-Carbide

[XXI] https://periodictable.com/element/074/Pictures.html

[XXII] https://www.istiGockphoto.com/de/bot-wall?Retururn%2FDE%2FPHOTOS%2FTungSten-Carbide-Drill-Bits

[XXIII] https://www.hyperionmt.com/en/resources/materials/cemented-carbide/cemed-carbide-hardness/

[XXIV] https://www.shutterstock.com/search/tungsten-carbide

[XXV] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-designers_Guide_tungstencarbide.pdf

[XXVI] https://tock.adobe.com/search?k=carbide

[XXVII] https://www.syalons.com/2024/07/08/silicon-carbide-vs-tungsten-carbide-wear-aplicsit/

[XXVIII] https://eurobalt.net/blog/2022/03/28/ALL-The-Application-Of-TungSten-carbide/

[XXIX] https://www.ruihantool.com/technic-data/understanding-The-hardness-of-carbide-end-mills.html

[XXX] https://www.tungco.com/insights/blog/5-tungsten-carbide-aplicsit/

[XXXI] https://www.azom.com/article.aspx?articleid=4827

[XXXII] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[XXXIII] https://wwwj-tool.com/material

[XXXIV] https://www.industrialplating.com/materials/tungsten-carbide-coatings

[XXXV] https://www.ohiocarbonblank.com/metallic-materials/tungsten-carbide

[XXXVI] https://www.practalmachinist.com/forum/threads/carbide-hardness-of-drill-and-end-mills.294897/

[XXXVII] https://www.tungstenringscenter.com/faq

[XXXVIII] https://www.tungstenrepublic.com/tungsten-carbide-rings-faq.html

[XXXIX] https://www.larsonjewelers.com/pages/tungsten-rings-pros-cons-facts-myths

[XL] https://www.bladorums.com/threads/carbide-hardness-data.1514372/

[XLI] https://etertrungsten.com/frequently-asked-questions-faqs

[XLII] https://www.menstungstenonline.com/frequently-asked-questions.html

[XLIII] https://www.reddit.com/r/askscience/comments/f02z1/materials_science_question_why_does_an_exremely/

[XLIV] https://www.tungstenringsco.com/faq

[XLV] https://unbreakableman.co.za/pages/all-about-tungsten-carbide-faq

[XLVI] https://www.practalmachinist.com/forum/threads/hardening-tungsten.405013/

[XLVII] https://tuncomfg.com/bout/faq/

[XLVIII] https://www.reddit.com/r/metallurgy/coms/ub4dg9/question_about_tungsten_carbide_toxicity/

[XLIX] https://www.mitsubishicarbide.net/Contents/MMSubis/Information/Information/Harness.html

[L] https://www.carbideprobes.com/wp-content/uploads/2019/07/tungstencarbidedatasheet.pdf

[LI] https://www.vistametalsinc.com/tungsten-carbide-grade-chart/

[LII] https://en.wikipedia.org/wiki/tungsten_carbide

[LIII] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[LIV] https://www.alamy.com/stock-photo/tungsten-carbide.html

[LV] https://konecarbide.com/what-is-tungsten-carbide/

[LVI] https://www.bangerter.com/en/tungsten-carbide

[LVII] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[LVIII] https://www.demetalloys.co.uk/what-is-tungsten-carbide/tungsten-carbide-grades-applications

[LIX] https://www.tungstenman.com/tungsten-carbide-hardness.html

[LX] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-selection.html

[LXI] https://www.tungworld.com/pages/faq

[LXII] https://tungstentitans.com/pages/faqs

[LXIII] https://www.thermalspray.com/questions-tungsten-carbide/

[LXIV] http://www.machinetoolrecyclers.com/rita_hayworth.html