Contentus menu

● Introductio ad Tungsten Carbide

● Rudis materiae

● Manufacturing processus Overview

● Detailed gradus in vestibulum processus

>> I. Powder Praeparatio

>> II. Mixing

>> III. Compaction

>> IV. Deining

>> V. machining

>> VI. Finishing

● Quality imperium mensuras

● Applications of Tungsten Carbide

● Auctoria Tungsten Carbide

● Challenges in vestibulum Tungsten Carbide

● Future Trends in Tungsten Carbide Vestibulum

● Conclusio

● Frequenter Interrogata Quaestiones (FAQ)

>> I. Quid est Tungsten Carbide de?

>> II. Quam difficile est Tungsten carbide comparari aliis materiae?

>> III. Potest Tungsten carbide et Recycled?

>> IV. Quid industrias vulgo uti Tungsten carbide?

>> V. Quid sunt beneficia usus Cobalt sicut ligans in Tungsten carbide?

● Citations:

Tungsten carbide (WC) est valde durabile materia notum est eximium duritiam et gerunt resistentiam, faciens illud essentiale component in variis industriae applications, inter cutting instrumenta, metalla, et gerunt-repugnant. Hoc articulum DENDVS in intricate vestibulum processus Tungsten carbide, detailing uterque gradum a rudis materia praeparatio ad ultima uber.

Introductio ad Tungsten Carbide

Tungsten carbide est a eget compositis compositis ex Tungsten et ipsum atomorum. Est claretur pro duritia, ranking inter IX et 9.5 in Mohs scale, faciens ea fere ut difficile sicut adamantino. Typicam compositionem Tungsten carbide est circa XCIV% Tungsten et VI% carbonis per pondus. Hoc unique structuram concedit Tungsten carbide eius insigni mechanica proprietatibus, quos possidet princeps density (circiter 15.6 g / cm³) et optimum scelerisque stabilitatem.

Rudis materiae

Productio Tungsten carbide involves aliquot clavis rudis materiae:

- Tungsten ore: primaria fontem Tungsten est typically in ores ut Wolframite et Scheelite.

- Carbon Sources: Carbon est plerumque a Graphite aut ipsum nigrum.

- Metals, Cobalt vel Nickel saepe usus est in ligans ad augendae et roughness et ductility of ultima uber.

Manufacturing processus Overview

Vestibulum processus Tungsten carbide potest destructa in pluribus discrimine;

I. Powder Praeparatio

Primum scaena involves parare Tungsten Pulvis per varii modi:

- reductionem Tungsten cadmiae: Tungsten cadmiae (Wo₃) reducitur in hydrogenii atmosphaera ad producendum Tungsten metallum pulveris.

- Carburization: Tungsten metallum pulveris est ergo mixta cum carbon fontes et subiecta alta temperaturis (typice inter MCD ° C ° C) ad formare Tungsten carbide per eget elit.

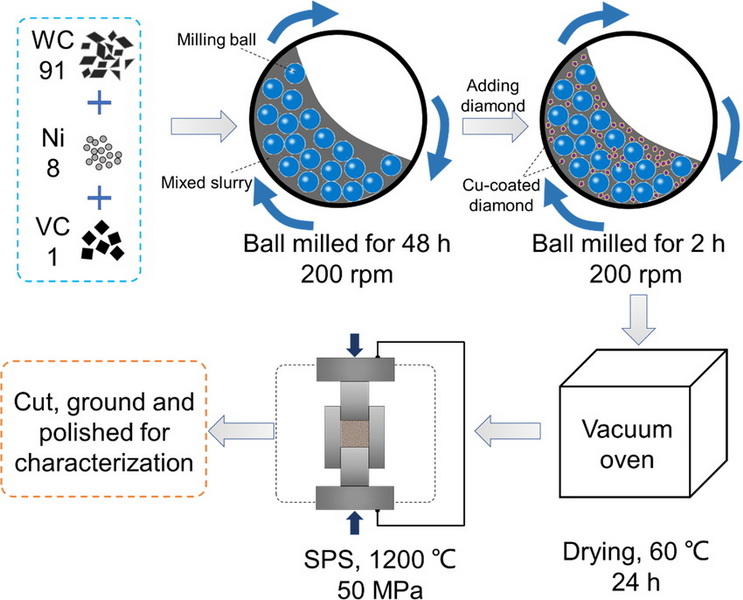

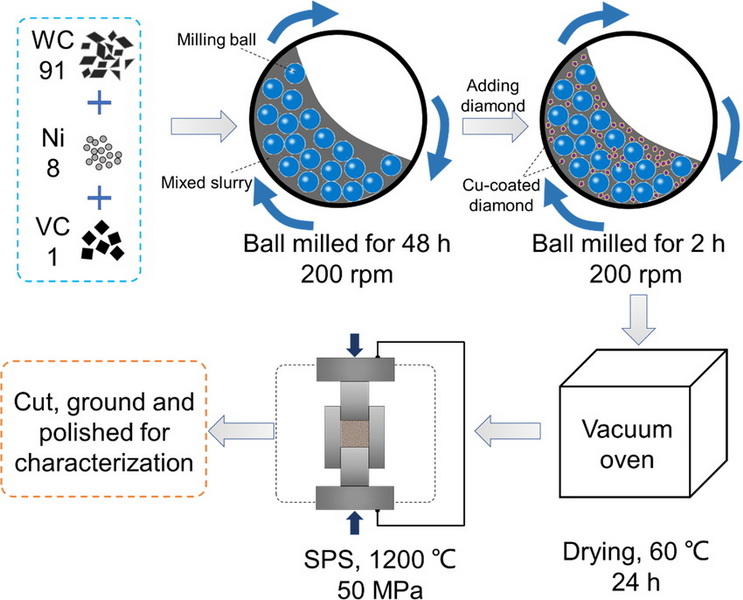

II. Mixing

In Tungsten carbide pulveris est mixta cum ligans metallis (sicut Cobalt) in pila molendini ut uniformis distribution. Hoc quoque mixtisque potest includere additives ad amplio specifica proprietatibus.

III. Compaction

Post miscentes, in pulveris mixtisque est coniuncta in figuras usura aut uniaxial urgeat aut Isostatic urgeat modi. Hoc gradum formae 'viridi ' partes qui sufficienti viribus tractantem sed nondum plene densa.

IV. Deining

Partes est crucial gradum ubi compactum partibus calefacti sunt in fornacem ad temperaturis vndique a MCD ° C ad MDC ° C in vacuo vel iners atmosphaera. Per hoc processus, in ligans et vincula in Tungsten carbide particulas simul, unde in solidum, densa materia.

V. machining

Post-Deining, in Tungsten Carbide components potest subire machining processus ut molere, milling, aut electrica missionem machining (Edm) ad consequi precise et superficies finiatur.

VI. Finishing

Denique, superficies treatments talis ut politur aut coating potest applicari ad augendae gerunt resistentia et amplio superficiem qualis.

Detailed gradus in vestibulum processus

I. Powder Praeparatio

Praeparatio Tungsten carbide pulveris involves plures modi

- Carburization reactionem: Tungsten metallum Reacts cum Carbon ad altum temperaturis ad formare WC:

W + c → WC

- temperatus potestate: et temperatus in hoc reactionem significantly afficit grano magnitudine et proprietatibus ex fit Tungsten carbide. Altior temperaturis tendunt ad producendum meliorem grana, quae potest augendae duritia sed etiam ad fragtileness, si non regitur proprie.

II. Mixing

In hoc gradu:

- pila milling, quod mixta pulveris positus in pila molendini additives sicut paraffin cera ad amplio vires vires.

- Uniformitatem reprehendo: cursus est mixtisque est homogenea est crucial pro consistent qualis in ultima uber. Insufficiens miscentes potest ad infirma maculis in ultima pars.

III. Compaction

Hoc processus involves:

- urgeat artes: usura mechanica aut hydrau premit ad pacto pulveris in desideravit shapes.

- Green Density Mensurae: Cras Green Density adjuvat praedicere quam bene pars erit Pirter. A superiore viridi densitas typice correlates cum meliorem peccating eventus.

IV. Deining

Key facies includit:

- Controllated atmosphaera: De Sinctering occurs in coerceri environment ne oxidatio et ensure propriis vinculum.

- Temperature Profile: A graduum incremento in temperatus iuvat adolebitque quisquam ligula prius pertingens sintoring temperaturis. Hoc diligenter imperium minimizes defectibus et ensures uniformis densitas in component.

V. machining

Ob extrema duritia:

- Specialized Tools: Diamond Pectus-praefixa Tools sunt saepe requiritur ad machining Tungsten carbide.

- Precision techniques: princeps praecisione est necessarium ad consequi stricta tolerances et desideravit superficies finiatur. Techniques ut CNC machining sunt communiter usus est.

VI. Finishing

Consummatione processibus ut involvere:

- Polising: Achieving lenis superficies consummavi per Diamond Polutio componit.

- coating treatments: Applicando coatings velut PVD (corporalis vapor depositione) Enhances gerunt resistentia longius.

Quality imperium mensuras

Qualis imperium est paramaunt per vestibulum processus Tungsten carbide. Variis artes sunt usus ut quisque batch occurrat restrictia cubits:

- Particle Size Analysis: ensures quod pulveris usus est ad vestibulum habet particulam magnitudinum, quae afficit peccating moribus et ultima proprietatibus.

- Density Testing: Tum viride density et Sinai density sunt metiri usura artes sicut Archimedes 'principle seu X-Ray computat Tomo (CT) scans.

- Microstuctural examination: Scanning Electron Microscopy (Sem) potest esse analyze frumenti structuram et deprehendere aliqua defectus in materia.

Applications of Tungsten Carbide

Tungsten Carbide scriptor unique proprietatibus idoneam variis applications:

- Cutting Tools: usus extensive in terebras, finis mola, et vidit laminas debitum ad duritiam.

- Mining Equipment: components sicut terebro bits et metalla tips prodesse ex eius gerunt resistentia.

- Industrial Machinery partibus: usus est in partes, qui requirere princeps diuturnitatem in extrema condiciones.

- Jewelry faciens: Tungsten Carbide scriptor scalpere resistentia facit eam popularibus ad nuptias vincula et aliis jewelry items.

Auctoria Tungsten Carbide

Et commoda usura Tungsten carbide super alia materiae includit:

I. Exceptional duritia: et duritia concedit ad iam tool vitae comparari ad vexillum ferro instrumenta.

II. Gerunt resistentia: Tungsten carbide components potest resistere significant gerunt ex abrasive materiae, faciens ea specimen pro dura environments.

III. High density: et princeps density confert ad stabilitatem in operationem, reducendo vibrationum in secandum applications.

IV. Thermal Stabilitatem: Tungsten carbide maintains suas proprietatibus ad elevatum temperaturis melius quam multis aliis materiae.

V. Versatility, quod potest esse in variis formis-puluerem, solidum caudices, aut iactaret superficies-faciens ut adaptabile pro numerosis applications.

Challenges in vestibulum Tungsten Carbide

Quamvis sua commoda, vestibulum Tungsten carbide munera challenges:

I. Integris Dum durum, Tungsten carbide potest fragile; Ita diligenter consilio considerari oportet vitare fracturae in usu.

II. Cost of Rudis Materials: et sumptus Tungsten ore potest fluctuare significantly secundum forum demanda et geopolitical factores.

III. Environmental de: et metalla procedit involved in extractionem Tungsten ore potest habere environmental impacts quod opus addressing per sustineri exercitia.

IV. Complex vestibulum processus: Quisque gradus requirit praecisione; Aliqua deviationis potest consequuntur in defectibus, qui compromissum perficientur.

Future Trends in Tungsten Carbide Vestibulum

Vultus praemisit, plures trends sunt emergentes in vestibulum Tungsten carbide:

I. Eminent Vestibulum (3D printing): Acta in additive vestibulum techniques sunt, initium patitur pro magis universa geometries, quae sunt ante difficile vel impossibile ad consequi cum traditional modi.

II. Sustainable Exercitia: nisus est facta ad magis sustineri mining exercitia et redivivus processus pro usus Tungsten Carbide Tools.

III. Nanostructured Materials: Research in Nanostructured versions of Tungsten Carbide potuit ducere usque ad etiam magis materiae cum improved lenta et gerunt resistentia proprietatibus.

IV. Dolor vestibulum Technologies: Integration IOT (Internet de rebus) Technologies in vestibulum processus posset augendae et imperium in productio parametri, ducens ad melius qualitas affirmatio.

Conclusio

In vestibulum processus Tungsten carbide combines Advanced materiae scientiae cum praecise ipsum artes. Ex rudis materia praeparatio per peccare et consummatione, quisque gradum ludit a vitalis munus in ensuring quod finalis productum occurrit rigorous perficientur signa requiritur a variis industrias. Sicut technology progreditur, innovations ut dictum est vestibulum incipit ut revolutionize quam Tungsten carbide components sunt produci, offering novum possibilities ad consilium et applicationem.

Frequenter Interrogata Quaestiones (FAQ)

I. Quid est Tungsten Carbide de?

Tungsten carbide est composito praesertim de partibus Tungsten (W) et ipsum (c), formatam a eget compositis eximia duritia.

II. Quam difficile est Tungsten carbide comparari aliis materiae?

Tungsten carbide ranks inter IX et 9.5 in Mohs duritiam scale, faciens illud unum de durissima materiae praesto, secundo modo adamantino.

III. Potest Tungsten carbide et Recycled?

Ita, Tungsten carbide potest esse recycled efficaciter; Exeo-ex tools potest reclaodie et reused in novus products.

IV. Quid industrias vulgo uti Tungsten carbide?

Industria ut fodienda, vestibulum (Cutting Tools), Aerospace et oleum EXERCITATIO frequenter utilitas Tungsten Carbide Ob suam diuturnitatem et perficientur sub accentus.

V. Quid sunt beneficia usus Cobalt sicut ligans in Tungsten carbide?

Cobalt enhances lenta et ductility dum maintaining princeps duritiam campester in cemented carbides, faciens eos magis resiliet contra fractura in usu.

Citations:

[I] https://heegermaterials.com/blog/90_how-is-tungsten-carbide-made-.html

[II] https://www.bangerter.com/en/tungsten-carbide/Manufacturing-Process

[III] https://www.carbide-part.com/blog/tungsten-carbide-machining-procascepess/

[IV] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide

[V] https://shop.Machinemfg.com/tungsten-carbide-an-overs

[VI] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[VII] https://www.zgccarbide.com/news/The-Manufacturing-Precess-of-Comented-Carbide-IsTs:-A-ComPisisting-Guide-39.html

[VIII] https://en.wikipedia.org/wiki/tungsten_carbide

[IX] https://www.kovametalli-in.com/manufacturing.html

[X] https://www.linde-amt.com/resource-library/Articles/tungsten-carbide

[XI] https://www.youtube.com/watch?v=95ys7W66-BI

[XII] https://eterterols.com/blogs/tutorials/tungsten-carbide-an-informive-guide

[XIII] https://www.tool-tool.com/news/201202/Cutting-Tool-Manufacturing-Process/index.html

[XIV] http://www.tungsten-carbides.com/news/carbide_manufacturing_press.html

[XV] https://todaysmachiningworld.com/magazine/how-it-works-making-tungsten-carbide-cutting-tools/

[XVI] https://Repository.Ap.Za/Bitstream/Handle/2263/24896/03Chapter3/24896/03Chapter3.pdf?sequence=4

[XVII] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/prascess.html

[XVIII] https://huanatools.com/how-to-make-tungsten-carbide-rods/

[XIX] https://patents.google.com/patent/us4008090a/en

[XX] https://www.xa-blt.com/en/news/revolutionizing-blten-carbide-manufacturing-blts-additive-manufacturing-technology-aproach-unveed-at-tct-asia-2023/

[XXI] https://ceramics.org/caramic-tech-today/tungnment-made-easy-government-industry-academia-investigate-Additively-Manufacturing-Cemed-carbide-parts/

[XXII] https://www.alamy.com/stock-photo/tungsten-carbide.html

[XXIII] https://generalcarbide.com

[XXIV] https://www.Evyrty-cemented-carbide.com/en/prascess/

[XXV] https://create.vista.com/photos/tungsten-carbide/

[XXVI] https://www.carbide-part.com/blog/tungsten-carbide-machining-procascepess/

[XXVII] https://consolidatedresources.com/blog/10-facts-about-tungsten-carbide/

[XXVIII] https://generalcarbide.com/pdf/general-carbide-designers-guide-tungsten-carbide.pdf

[XXIX] https://www.researchgate.net/topic/tungsten

[XXX] https://www.yatechmaterials.com/en/news/production-process-and-equipment-of-tungsten-carbide-power/

[XXXI] https://www.hit-tw.com/newsdetails.aspx?nid=298

[XXXII] https://www.tungco.com/insights/blog/frequently-asked-quests-ed-tungsten-carbide-inserts/