Contentus menu

● Quid Tungsten carbide?

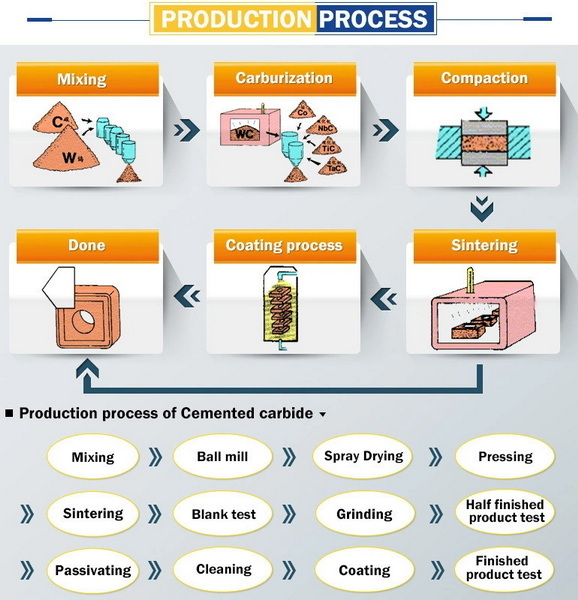

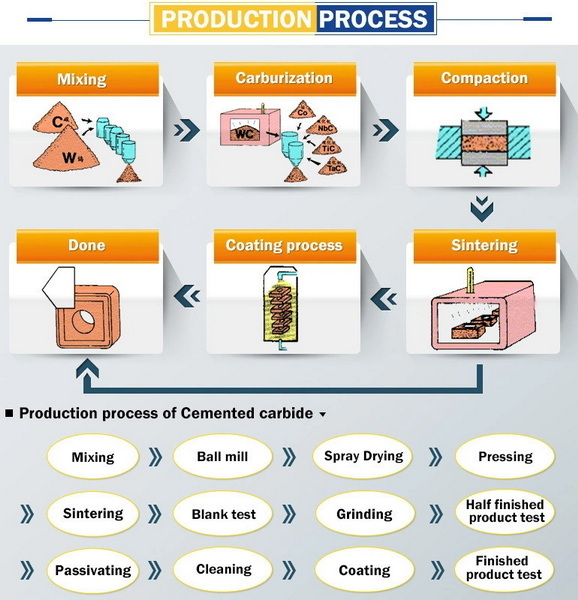

● Et mittentes processus of Tungsten Carbide

>> I. Praeparatio rudis materiae

>> II. Mixing

>> III. Liquid

>> IV. Projicientes

● Applications de Cast Tungsten Carbide

>> Detailed Applications

● Utilitatum mittendi Tungsten Carbide

● Challenges in casting Tungsten Carbide

● Innovations in Tungsten Carbide casting

● Future trends in Tungsten Carbide casting

● Conclusio

● FAQs

>> I. Quid sunt principalis components in casting Tungsten carbide?

>> II. Quid est Tungsten carbide sic dura?

>> III. Potest tungsten carbide et machined iuxta casting?

>> IV. Quod industries beneficium ex usura cast tungsten carbide?

>> V. Quomodo facit proiectio processus afficit proprietatibus Tungsten carbide?

● Citations:

Tungsten Carbide (WC) est compositis factum ex Tungsten et ipsum, notum est eius eximia duritia et gerunt resistentia. Hoc articulum explorat mittentem Tungsten carbide , sua proprietatibus, applications et modi involved in sua productione. Nos mos quoque DELVE in commoda et challenges consociata cum hoc processum, providente comprehendo intellectus huius mirabiliter materia.

Quid Tungsten carbide?

Tungsten carbide est densa, metallicum compositis composito ex partibus Tungsten et ipsum. Est propria per altum duritiam, faciens illud unum de durissima materiae praesto, secundo modo adamantino. In materia est molecular pondus 195.85 et saepe in industriae applications debitum ad unicum proprietatibus.

Properties Tungsten Carbide:

- Durness: simile adamantino.

- densitas: circa duplex quod de ferro.

- Thermal stabilitatem: potest sustinere altum temperaturis sine amissis structural integritas.

- Gere Resistance: Highly repugnant abrasione et gerunt.

- ROSIO resistentia: repugnant multis acidis et oeconomiae.

Et mittentes processus of Tungsten Carbide

Misering Tungsten carbide involves aliquot gradus, quae includit miscentes Tungsten pulveris cum ipsum, liquescens mixtisque, et mittentes eam in fingit. Processus potest variari fretus in desideravit proprietatibus finalis uber.

I. Praeparatio rudis materiae

Primum gradum in casting Tungsten carbide est parat rudis materiae. Hoc involves:

- Tungsten Powder: typically 95-96 WT% de mixtisque.

- Carbon Powder: De 3.95-4.10 WT% ad curare proper carbide formationem.

Et qualis harum rudis materias significantly impingit ad ultima productum est perficientur habet. High-puritas Tungsten et ipsum Pulvis malle ad minimize impudicitiis quae posset afficit duritia et gerunt resistentia.

II. Mixing

Et Tungsten et ipsum Pulveres penitus misceri ad consequi homogenea miscetur. Hoc gradum est crucial pro ensuring proprietatibus per conject uber. Variis miscentes artes potest adhiberi, comprehendo mechanica mixtione et pila milling, quae adjuvat consequi uniformis particula magnitudine distribution.

III. Liquid

Et mixta pulveris tunc subiecta alta temperaturis (vndique a MMDCC ° C ad C ° F) in Founding fornacem. Hoc processus transformat pulverem in fusum Tungsten carbide. Melting processus requirit specialized apparatu capaces talis temperaturis dum maintaining aeris ne oxidatio.

IV. Projicientes

Semel liquefactum, in Tungsten carbide infunditur in formam ubi refrigerat et solidatur. Et refrigerationem processus potest esse ad consequi specifica microstructures quod augendae perficientur habet. Diversa refrigerationem rates potest ducere ad variationes in duritia et lenta in ultima uber.

Applications de Cast Tungsten Carbide

Tungsten Carbide scriptor unique proprietatibus idoneam ad amplis applications:

- Cutting Tools: usus est in vestibulum terebras, milling cutters, et vidit laminas debitum ad duritiam et gerunt resistentia.

- Mining Equipment: Essential pro EXERCITATIO bits et alia instrumenta in dura environments.

- Jewelry: eius diuturnitatem facit eam popularibus ad nuptias vincula et aliis jewelry items.

- Industrial Machinery: components quod requirere altum gerunt resistentia prodesse ex Tungsten carbide coatings vel adiicit.

- Aerospace components: usus est in partes, ut resistere extrema condiciones.

Detailed Applications

I. Cutting Tools:

Tungsten carbide secans instrumenta late in machining operationes ex facultatem ad ponere acuti acuti longior quam traditum ferro instrumenta. Sunt usus in variis industrias, inter automotive, aerospace et metalworking.

II. Mining Equipment:

In Mining Operations, Tungsten Carbide adhibetur ad terebro bits ut penetrare petra formations. Et gerunt resistentia ensures iam tool vita, reducing downtime et sustentationem costs.

III. Jewelry:

Tungsten carbide est popularis in jewelry foro pro nuptialem vincula et fashion annulos debitum ad eius scalpere, repugnans superficiem et modern Aesthetic appeal.

IV. Industrial Machinery:

Components sicut gestus, valvulae et nozzles ex Tungsten carbide exhibent superior perficientur in extrema condiciones, faciens ea specimen pro gravibus machinery applications.

V. Aerospace Components:

In Engineering aerospace, Tungsten carbide adhibetur pro components quod requirere princeps viribus, ut-pondus componat cum maintaining diuturnity sub accentus.

Utilitatum mittendi Tungsten Carbide

Misering Tungsten carbide offert pluribus commoda super aliis vestibulum modos:

- High praecisione: et mittens processus potest producendum intricate figuras cum stricta tolerances.

- Enhanced proprietatibus: coolered refrigerationem concedit ad tailored microsctructures ut amplio duritiem et gerunt resistentia.

- Cost-efficaciam: magna-scale productio potest reducere costs comparari machining solidum Tungsten carbide caudices.

- Versatility, quod facultatem adjiciamus complexu geometries expands consilio possibilities pro fabrum et gravida.

Challenges in casting Tungsten Carbide

Quamvis sua commoda, casting Tungsten carbide praesentibus quibusdam challenges:

- In Flos: Pura Tungsten carbide potest esse fragile; Ut, sic additives sicut Cobalt et Titanium sunt saepe includitur ad amplio lenta.

- Cobalt acts ut a Blackengat, quae enhances lenta dum maintaining duritia.

- Titanium potest conflentur granum structuram, ulterius improving perficientur characteres.

- Complexitate processu: et princeps temperaturis requiritur ad liquescens demanda specialized apparatu et salus provideri.

- Operators debet esse erudienda tractare ancipitia materiae tuto.

- Environmental controls sunt necessaria ad administrare emissiones durante liquescens.

Innovations in Tungsten Carbide casting

Recens progressiones in technology ducitur ad innovations in mittentem processus of Tungsten carbide:

I. Enumerabilis vestibulum:

- Techniques quasi 3D printing sunt explored pro creando complexu figuris per Tungsten carbide compositorum.

- Hic modus concedit in celeri prototyping et reducitur vastum durante productio.

II. Pulvis Metallurgy:

- Metallurgy combining Metallurgy Techniques cum traditional mittentes modi enhances in materia proprietatibus Tungsten carbide.

- Hic accedens permittit pro meliorem imperium in particula magnitudine distributio et compositionem.

III. Recycling:

- Cum crescente environmental de, redivivus Scrap Tungsten carbide est facti magis momenti.

- RECYCLING processus enable artifices ad invocare valuable materiae dum redigo vastum.

Future trends in Tungsten Carbide casting

Ut industries permanere evolve, pluribus trends verisimile ad figura futura Tungsten Carbide casting:

I. Sustainability initiatives:

- Manufacturers erit focus in sustineri exercitia per obscuratis perditio durante productio processibus.

- Development of Eco-amica ligula, ut lucrum tractu ut environmental ordinationes facti strictior.

II. Smart Manufacturing:

- Integration IOT (Internet de rebus) Technology in vestibulum processus erit augendae magna elit.

- Verus-vicis notitia collectio potest ducere ad melius qualis imperium per casting operationes.

III. Customization:

- Ut mos petit subcinctus ad personalized products, manufacturers potest offerre customized solutions utilizing proficiebat casting artes.

- Tailored formulae posset ad unicum proprietatibus idonea ad specifica applications.

Conclusio

Misering Tungsten carbide est complexu adhuc praemiando processus qui leverages ad unicum proprietatibus huius material creare summus perficientur products trans variis industries. Eius applications range ex secans instrumenta ad aerospace components, showcasing ejus versatility et momenti in modern vestibulum. Quamvis challenges ut fragtileness et complexionem processus involved, permanentis innovations promittere clara futura pro Tungsten carbide mittentem.

FAQs

I. Quid sunt principalis components in casting Tungsten carbide?

Pelagus components sunt Tungsten Pulvis (95-96 WT%) et Carbon Pulvis (3.95-4.10 WT%).

II. Quid est Tungsten carbide sic dura?

Tungsten carbide scriptor duritia est a fortis covalent vincula inter Tungsten et ipsum atomos, formatam rigidum crystal structuram.

III. Potest tungsten carbide et machined iuxta casting?

Ita, sed hoc requirit specialized tools debitum ad duritiam.

IV. Quod industries beneficium ex usura cast tungsten carbide?

Industria ut fodienda, vestibulum, aerospace et jewelry prodesse significantly de cast Tungsten carbide ex suo diuturnitatem et gerunt resistentia.

V. Quomodo facit proiectio processus afficit proprietatibus Tungsten carbide?

Et mittentes processus concedit ad imperium refrigerationem rates, quod potest augendae duritiam et tailour microstructures ad propria applications.

Citations:

[I] https://patents.google.com/patent/cn1546713a/en

[II] https://www.refractorsetal.org/tungsten-carbide-useses-properties.html

[III] https://www.samaterials.com/tungsten-carbide/1106-casting-tungsten-carbide-powder.html

[IV] https://www.tungco.com/insights/blog/5-tungsten-carbide-aplicsit/

[V] https://patents.google.com/patent/us5089182a/en

[VI] https://www.sollex.se/en/blog/post/about-cemed-tungsten-carbide-apply-part-1

[VII] https://rocklinmanufacturing.com/resources/files/yr/2020/die_casting_engineer_editorial_-_sept_20.pdf

[VIII] https://en.wikipedia.org/wiki/tungsten_carbide

[IX] https://eurobalt.net/blog/2022/03/28/ALL-The-Application-Of-TungSten-carbide/