Contentus menu

● Introductio ad Tungsten Carbide

>> Proprietatibus Tungsten carbide

● Coatings in Tungsten Carbide

>> I. Titanium Nitride (stannum) coatings

>> II. Aluminium Oxide (Al2o3) coatings

>> III. Chromium carbide (CR3C2) coatings

>> IV. CVD Tungsten Carbide coatings

>> V. Diamond Pectus, sicut Carbon (DLC) coatings

● Applications de iactaret tungsten carbide

● Beneficia de coatings in Tungsten Carbide

● Challenges et futurum developments

● Conclusio

● Faq

>> I. Quid sunt primaria beneficia applicandi coatings ad Tungsten carbide?

>> II. Quod coating est optimum ad altus-temperatus applications?

>> III. Can CVD Tungsten carbide coatings adhiberi in mordendo environments?

>> IV. Quam operor stagni coatings meliorem instrumentum perficientur?

>> V. Quid est typicam crassitudine CVD Tungsten carbide coatings?

● Citations:

Tungsten carbide est clarus est eius eximia duritia et gerunt resistentia, faciens illud crucial materia in variis industriae applications, de instrumenta ad aerospace components. Sed non obstante sua robust possessiones, Tungsten carbide potest prodesse ex additional coatings ad augendae eius perficientur, praesertim secundum corrosio resistentia et superficiem metam. Hoc articulum explorat genera coatings, quod potest applicari ad Tungsten carbide, applications et beneficia providere.

Introductio ad Tungsten Carbide

Tungsten carbide (WC) est a eget compositis composito de Tungsten et ipsum atomos, notum est summus duritia et liquescens punctum. Est saepe in forma cermet, ubi Tungsten carbide particulas sunt alligatus cum metallicis matrix, typice Cobalt vel nickel, ad augendae ductility et lenta.

Proprietatibus Tungsten carbide

- Durness: Tungsten carbide est unus de durissima materiae usus est in industriae applications, cum duritia, quae potest excedunt XC in Rockwell C.

- Gerunt resistentia: et offert optimum resistentiam ad induendum et abrasion, faciens idealis pro usu in altum gerunt ambitus.

- Thermal proprietatibus: Tungsten carbide habet altum liquescens punctum et bonum scelerisque conductivity, quae sunt utilis in summus temperatus applications.

Coatings in Tungsten Carbide

Dum Tunsten carbide se praebet optimum gerunt resistentiam, additional coatings potest augendae eius perficientur per meliorem corrosio resistentia, reducendo friction, aut assequendum specifica superficies finiatur.

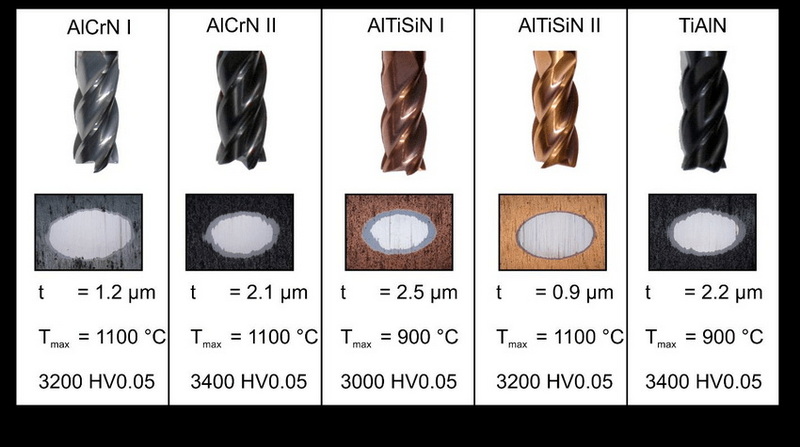

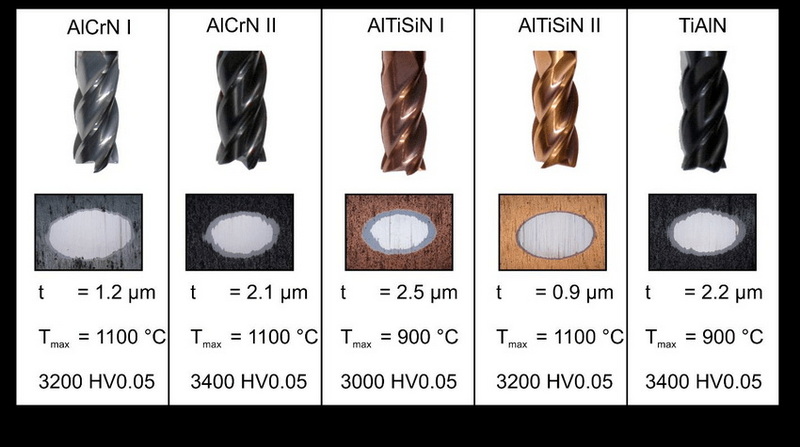

I. Titanium Nitride (stannum) coatings

Titanium nitride coatings sunt communiter applicantur ad Tungsten Carbide Tools ad amplio superficiem duritiam et redigendum friction. Tin coatings notum est in aureum color et saepe in cutting tools ad augendae gerunt resistentia et reducere instrumentum gerunt durante machining operationes.

II. Aluminium Oxide (Al2o3) coatings

Aluminium Oxide coatings sunt ad providere additional gerunt resistentia et scelerisque. Sunt praecipue utile in summus celeritas machining applications ubi calor build potest esse a significant exitus.

III. Chromium carbide (CR3C2) coatings

Chromium carbide coatings offerre optimum corrosio resistentia et saepe in environments in quo et lapsum et corrosio sunt. Haec coatings sunt praecipue utilis in eget dispensando et Marine Applications.

IV. CVD Tungsten Carbide coatings

Chemical vapor depositione (cvd) Tungsten carbide coatings provectus Nano-exstructa materiae quod providebit auctus duritia et lenta sine opus Cobalt et Nickel ligula. Haec coatings sunt specimen pro applications requiring altum gerunt resistentia et corrosio praesidio, ut in aerospace et oleum EXERCITATIO apparatu.

V. Diamond Pectus, sicut Carbon (DLC) coatings

Diamond Pectus, sicut carbonis coatings notum est humilis friction et altum gerunt resistentia. Sunt saepe applicari ad Tungsten carbide components in illapsum contactus aut ubi reducitur frictio est critica, ut in mechanica signacula et gestus.

Applications de iactaret tungsten carbide

Iactaret Tungsten carbide components sunt usus per varia industries ex eorum amplificata proprietatibus:

- Aerospace: coatings sicut stagni et al2o3 sunt in Turbine Laminae et engine components ut amplio gerunt resistentia et redigendum frictio.

- Oleum et Gas: CVD Tungsten Carbide coatings applicantur ad EXERCITATIO instrumenta ad augendae diuturnitatem in dura environments.

- Machining Tools: Tin et Al2o3 coatings sunt communia in cutting instrumenta ad extend tool vitae et amplio machining efficientiam.

- Automotive: DLC coatings sunt in engine components ad redigendum friction et amplio cibus efficientiam.

Beneficia de coatings in Tungsten Carbide

Et applicationem de coatings ad Tungsten carbide offert pluribus beneficia:

- Enhanced Corrosion resistentia: coatings sicut Chromium carbide providere additional praesidium contra corrosio.

- amplio superficies metam: coatings potest consequi specifica superficiem finiatur, reducendo friction et improving pars perficientur.

- Auxit Mors Principium Vita: Per reducendo gerunt et corrosio, coatings potest significantly extend in ministerium vitae instrumenta et components.

- Reducitur sustentationem, cum amplio diuturnitatem, iactaret Tungsten carbide components eget minus crebris sustentationem, reducendo downtime et costs.

Challenges et futurum developments

Quamvis commoda coatings in Tungsten carbide, ibi sunt challenges ut addressed:

- Adhaesiones exitibus: cursus fortis adhaesionem inter coating et subiectum est crucial pro maintaining perficientur.

- sumptus et complexionem: quidam coating processus potest esse pretiosa et complexu, limitando eorum lateque adoption.

- Environmental curam: usum quidam metallis in coatings elevat environmental curam, impartitum investigationis in magis sustineri alternatives.

Future developments in coating technology expectata ut focus in improving adhaesionem, reducendo costs, et developing environmentally amica coatings. Progressiones in Nanotechnology et usum Bio-inspiravit materiae sunt etiam promissum areas of investigationis.

Conclusio

Tungsten carbide est a versatile materia, quae potest esse adhuc amplificata variis coatings ad occursum propria applicationem requisita. Sive suus 'improving corrosio resistentia, reducendo friction, aut assequendum precise superficiem metam, coatings ludere a discrimine partes in maxima perficientur de Tungsten carbide components. Per intellegendum genera coatings praesto et applications, industries can optimize usum Tungsten carbide ad amplio efficientiam et redigendum sustentationem costs.

Faq

I. Quid sunt primaria beneficia applicandi coatings ad Tungsten carbide?

Et primaria beneficia includit amplificata corrosio resistentia, amplio superficiem metam, et auctus instrumentum vitae a reducendo lapsum et frictio.

II. Quod coating est optimum ad altus-temperatus applications?

Aluminium Oxide (Al2o3) coatings sunt utilis pro summus temperatus applications debitum ad scelerisque proprietates.

III. Can CVD Tungsten carbide coatings adhiberi in mordendo environments?

Etiam CVD Tungsten carbide coatings offerre optimum corrosio resistentia et apta usum in mordendo ambitibus.

IV. Quam operor stagni coatings meliorem instrumentum perficientur?

Tin coatings amplio tool perficientur per enhancing superficiem duritiam et reducing friction, quod adjuvat in extendendo tool vitae et improving machining efficientiam.

V. Quid est typicam crassitudine CVD Tungsten carbide coatings?

CVD Tungsten carbide coatings potest produci ad C microns densissima, quae est unique dura CVD coatings.

Citations:

[I] https://htscoatings.com/blogs/our-Craft-OrBoulture-Three-spray-CarBide-therMal-Spray-Coatings-and-Their-Uses

[II] https://www.thermalspray.com/need-tungsten-carbide-coatings/

[III] https://www.haydencorp.com/tungsten-carbide-coatings

[IV] https://www.precioncoatings.com/capabilities/Coatings/Carbide/

[V] httpsshsshsshsshssh.machinemfg.com/tung.com/StPs

[VI] https://www.industrialplating.com/materials/tungsten-carbide-coatings

[VII] https://www.asbindustries.com/coing-materials/carbide-coing-materials/tungsten-carbide-coatings

[VIII] https://hardide.com/wp-content/uploads/2020/05/corrosion_20101.pdf

[IX] https://htscoatings.com/pages/tungsten-carbide

[10] https://www.bruker.com/en/products-and-solutions/elemental-analyzers/eds-wds-ebsd-SEM-Micro-XRF/quantax-eds-for-sem/ticn-hard-coatings-for-tungsten-carbide-cutting-tools.html

[XI] https://www.linde-amt.com/resource-library/Articles/tungsten-carbide

[XII] https://www.samaterials.com/content/how-does-the-new-tungsten-carbide-coing-strengenthen-aircraarts.html

[XIII] https://ketico.com/coing-materials/tungsten-carbide-wc-co-coatings

[XIV] https://assets.linde.com/-/media/celum-connect/225/01/16/14/05/tungSten_Carbide_Calendar_roll_193694.jpg?impol glacialis = focal-punctum & C. = MCC & ch = DCXXX & fx = DLXXVI & FY = CL & R = B4085B0646 & SA = X & VED = 2ahukeWitWpNtcMaxwlk1ybhducngkq_b16bagiei

[XV] https://wwgineerlive.com/content/carbide-coatings

[XVI] https://www.ep-coatings.com/NEWS/Application-Of-TungSten-CarBide-Coatings-In-Aaerospace-INTRY.html

[XVII] https://www.atcgroup.com.au

[XVIII] https://www.oerlikon.com/metco/en/products-services/Materials/Carbides/

[XIX] https://www.sciendirect.com/science/article/abs/pii/s0263436821003048

[XX] https://www.arielcorp.com/support/application-manual/compride/cylinder/tungstencarbide.html

[XXI] https://ketico.com/wp-content/uploads/2016/11/hvobalt-prawco-tungsten-carbide-cobalt-strare-and-aplications.ppoperties-structure-and-Applications.png?sa=X&ved=2ahukewjcoumsntcaxvfcpuhhvl8i2cq_b16baghei

[XXII] https://www.gordonengland.co.uk/micRophotographs.htm

[XXIII] https://www.gettyimages.com.au/photos/tungsten-carbide

[XXIV] https://www.haydencorp.com/photo-gallery

[XXV] https://www.gordonengland.co.uk/pmg3.htm

[XXVI] https://www.alphatek.co.uk/what-is-hvof-tungsten-carbide-coating/

[XXVII] https://www.metalizingspecialists.com/past-projects-gallery/trymal-spray-tungsten-carbide-metallings-segs/

[XXVIII] https://www.hoganas.com/en/powder-technologies/surface-coing/products/hvof/carbides/

[XXIX] https://www.instagram.com/Quali.tech/reel/c9-vwrmoweg/

[XXX] https://www.thtray.com/hvaf-tungsten-carbide-throme-ping/

[XXXI] https://www.shutterstock.com/image-photo/spalling-tungsten-carbide-coing-on-planger-1434824261

[XXXII] https://www.nbcbearings.com/tungsten-carbide-carbon-coing-in-db/

[XXXIII] http://www.tungsten-carbide.com.cn/tungsten-carbide-coing.html

[XXXIV] http://www.wococarbide.com/uploads/2017-07-31/597edb1697a16.pdf

[XXXV] https://www.pcimag.com/articles/113102-new-tungsten-carbide-pders-for-hvof-applications